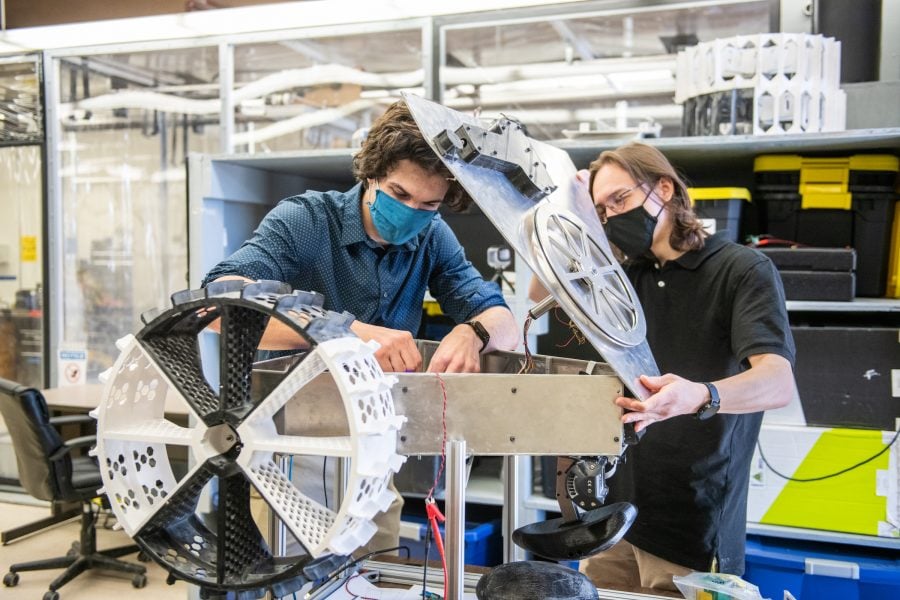

WLUC TV6 and the Daily Mining Gazette covered Engineering Day at Lake Linden Elementary School. The event was hosted by Michigan Tech’s Society of Women Engineers and Engineering Ambassadors Program on October 28, 2022.

Gretchen Hein (MMET) and undergraduate students Audrey Levanen and Julia Westfall (both mechanical engineering) were quoted by TV6.

Hein and undergraduate students Natalie Hodge (electrical and computer engineering) and Sam Jager and Robert Eckright (both mechanical engineering) were quoted by the Gazette.

Jaclyn Johnson (ME-EM) was mentioned in both stories.

The combined group engaged students with a variety of engineering activities. This included using tin foil boats to showcase buoyancy, making small-scale roller coasters, and even using batteries to make “robots” jump.