More than 1,000 students in Enterprise and Senior Design showcased their hard work last Thursday at Michigan Tech’s 22nd Annual Design Expo event. As we’ve come to expect, the judging for Design Expo is often VERY CLOSE. This year we had several ties.

Teams competed for cash awards totaling nearly $4,000. Judges for the event included corporate representatives, community members and Michigan Tech staff and faculty.

The Enterprise Program and College of Engineering are proud to announce the award winners. Check them out here, or visit the Design Expo website, at mtu.edu/expo, where you can view videos and project info submitted by all the teams who took part. Congratulations and a huge thanks to everyone for a very successful Design Expo!

ENTERPRISE AWARDS (Based on video submissions)

First Place (2-way tie)

CinOptic Communication/Media

Team Leaders: Matthew Brisson, Communication, Culture, and Media; Julianna Humecke, Scientific and Technical Communication

Advisor Erin Smith, Humanities

Sponsors: Isle Royale National Park, NSF CAREER Grant

Video

Velovations

Team Leaders: Jorge Povich and Eamon McClintock, Mechanical Engineering

Advisor Steve Lehmann, Biomedical Engineering

Sponsors: Cleveland Cliffs, Senger Innovations, Enterprise Program

Video

Second Place (2-way tie)

Aerospace Enterprise

Team Leaders: Nolan Pickett and Kyle Bruursema, Mechanical Engineering

Advisor: L. Brad King, Mechanical Engineering-Engineering Mechanics

Sponsors: Auris: Air Force Research Laboratory, Stratus: NASA

Video

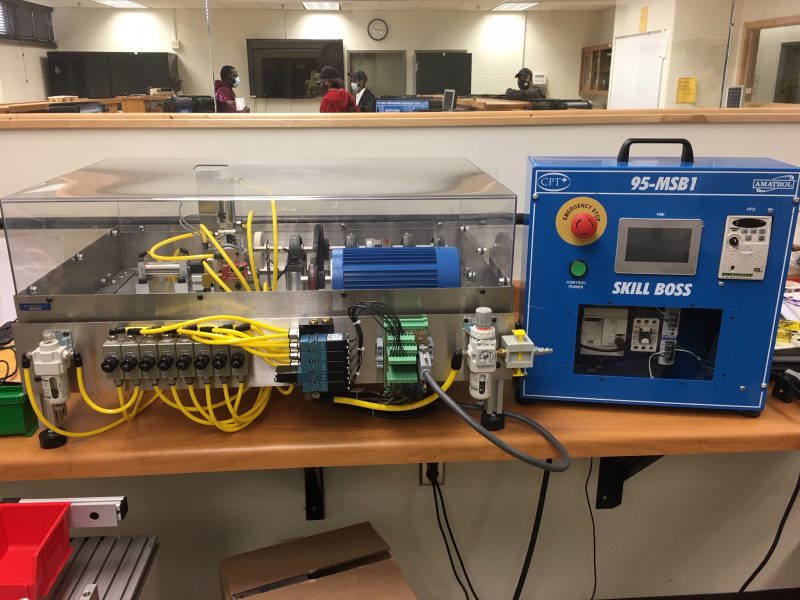

Supermileage Systems Enterprise

Team Leaders: Luis Hernandez, Mechanical Engineering and Olivia Zinser, Electrical Engineering

Advisor: Rick Berkey, Manufacturing and Mechanical Engineering Technology

Sponsors: General Motors, Aramco Americas, A&D Technology, Dana Inc., SAE International, Halla Mechatronics, Meritor, Oshkosh Corporation, Ford Motor Company, John Deere, Caterpillar, Henkel, BRP Inc., RapidHarness, Wetherington Law Firm, Danaher, Watermark, Top Flight Automotive, Shipley Energy, TEAMTECH, Gamma Technologies, Velocity USA, Enterprise Manufacturing Initiative funded by General Motors

Video

Third Place:

Clean Snowmobile Challenge

Team Leaders: Katy Pioch and Daniel Prada, Mechanical Engineering

Advisor: Jason Blough and Scott Miers, Mechanical Engineering-Engineering Mechanics

Sponsors: GM (General Motors), Aramco, A&D, Dana, Milwaukee Tool, Caterpillar, Meritor, Oshkosh, Ford, John Deere, BRP (Ski-Doo), Kohler, Mahle, Yamaha, Castle, Gamma Technologies, Quincy Compressor, Shipley Energy, Top Flight Automotive, Superior Graphics

Video

Honorable Mention:

Formula SAE

Team Leaders: John Herr and Luke Quilliams, Mechanical Engineering

Advisor: James DeClerck, Mechanical Engineering-Engineering Mechanics

Sponsors: General Motors, Aramco Americas, A&D Technology, Dana Inc., SAE International, Yamaha, Halla Mechatronics, Meritor, Oshkosh Corporation, Ford Motor Company, John Deere, Caterpillar, Henkel, BRP Inc., RapidHarness, Wetherington Law Firm, Danaher, Watermark, Top Flight Automotive, Shipley Energy, Superior Graphics, TEAMTECH, Gamma Technologies, Enterprise Manufacturing Initiative funded by General Motors

Video

SENIOR DESIGN AWARDS (Based on video submissions)

First Place

IoMT Device Security

Team Members: Jacson Ott, Stu Kernstock, Trevor Hornsby, and Matthew Chau, Cybersecurity

Advisor:Guy Hembroff, Applied Computing

Sponsor: Dept. of Applied Computing

Video

Second Place

MR Compatible Transseptal Needle with Integrated System for Confirming Left Atrial Access

Team Members: Lydia Ragel Wilson, Natalie Reid, Jared Martini, Braxton Blackwell, and Aydin Frost, Biomedical Engineering

Advisor: Hoda Hatoum and Jeremy Goldman, Biomedical Engineering

Sponsor: Imricor

Video

Third Place

Britten Water Filtration System

Team Members: Nika Orman and Nick Hoffebeck, Electrical Engineering, Matt Zambon, Kyle Clow, Luke Schloemp, and Gabby Sgambati, Mechanical Engineering, and Evan McKenzie, Computer Engineering

Advisor: Tony Pinar, Electrical and Computer Engineering

Sponsor: BoxPop powered by Britten, Inc.

Video

Honorable Mention 1

Locomotive Pinion Cutter Feed System

Team Members: Seth Jensen-Younk, Sam Barwick, Matt Krause, Nick Sand, and Stephen Mleko, Mechanical Engineering

Advisor: Cameron Hadden, Mechanical Engineering-Engineering Mechanics

Sponsor: Dr. Pasi Lautala, Civil, Environmental, and Geospatial Engineering

Video

Honorable Mention 2

Rapid Corrosion Screening of Engineered Structural Fastener Coating Systems for Treated Lumber

Team Members: Sophie Mehl, Isabelle Hemmila, and Kendal Kroes, Materials Science and Engineering and Luke Owens, Mechanical Engineering

Advisor: Paul Sanders, Materials Science and Engineering

Sponsor: Altenloh, Brinck & Company US, Inc

Video

Honorable Mention 3

Cycle Time Improvements in Medical Device Manufacturing – Laser Welding

Team Members: Abigail Martin, Hannah Loughlin, Zachary Alesch, and Megan Cotter, Biomedical Engineering

Advisors: Jeremy Goldman and Chunxiu (Traci) Yu, Biomedical Engineering

Sponsor: Boston Scientific (BSC)

Video

Honorable Mention 4

Stromberg Carlson Electric Tongue Jack Redesign Phase 2 Application Development

Team Members: Dustin Duclos, Sean Parker, and Shane O’Brien, Computer Engineering

Advisors: Trever Hassell and Mark Sloat, Electrical and Computer Engineering

Sponsor: Stromberg Carlson

Video

DESIGN EXPO IMAGE CONTEST (Based on image submitted by the team)

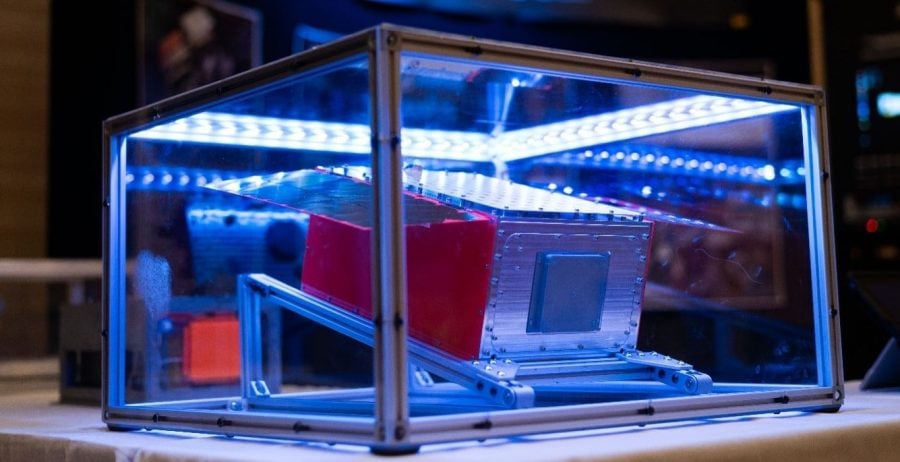

First Place:

Aerospace Enterprise — “Physical Model of Auris Spacecraft.”

Second Place:

Blizzard Baja Enterprise — “Blizzard Baja Competition Vehicle.” Photo credit: Andrew Erickson

Third Place

Dollar Bay School SOAR — “A member of the SOAR team troubleshoots one of the service grade ROVs.”

DESIGN EXPO INNOVATION AWARDS (Based on application)

First Place

Lydia Ragel Wilson, MR Compatible Transseptal Needle with Integrated System for Confirming Left Atrial Access, Department of Biomedical Engineering

Sponsor: Imricor

Second Place

Veronika Orman, Britten Water Filtration System, Department of Electrical and Computer Engineering

Sponsor: Britten, Inc.

Third Place

Jerod Warren, HACK Cybersecurity Kit, Department of Applied Computing

DESIGN EXPO AUDIENCE CHOICE AWARD (Based on receiving most text-in voting during Design Expo)

Enterprise

Consumer Product Manufacturing

Video

Senior Design

Britten Water Filtration System

Video

ENTERPRISE STUDENT AWARDS

Rookie Award: Brian Geiger, CFO, Multiplanetary Innovation Enterprise (MINE)

Innovative Solutions: Pete LaMantia, ITOxygen

Outstanding Enterprise Leadership: Brooke Bates, Consumer Product Manufacturing

ENTERPRISE FACULTY/STAFF AWARDS

Behind the Scenes Award: Tania Demonte Gonzalez, PhD Student Researcher, Department of Mechanical Engineering-Engineering Mechanics.

Outstanding Enterprise Advisor: Tony Rogers, Associate Professor and Faculty Advisor, Consumer Product Manufacturing, Department of Chemical Engineering