When Lean principles are fully understood and Lean tools are correctly applied, the opportunities for improvement and growth are endless. I have been a part of the Office of Continuous Improvement for almost a year and a half, and I have witnessed, numerous times, the benefits of successful Lean implementation. What I want to talk about today is why some organizations fail at becoming Lean.

Why is it that some organizations, or even some functional units within an organization, are able to successfully implement this methodology while others fail miserably? Short answer: Culture. The greatest mistake you can make on a Lean journey is taking a shortcut down Tool Avenue. Often times, in unsuccessful attempts at spreading Lean, one entity assumes it can achieve the same results as another simply by applying the same tools that the other has gotten positive results from. “Continuous Improvement” is therefore reduced to an “improvement project” and concern then arises when the improvement is not sustained.

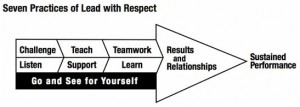

Lean will never be something you do, it is something you become. In order to truly become Lean, the entire value system of the organization must change. Commitment to Lean thinking and the establishment of a Lean culture give birth to successful Lean “implementation.” An organization’s culture and the principles that drive people’s behaviors ultimately determine the degrees of an organization’s performance, quality, and success. There is no concrete definition of what a “Lean culture” is, however there is one principle that all Lean enterprises do follow: respect for people.

In a 2007 eLetter, James P. Womack, Ph.D., founder and senior advisor to the Lean Enterprise Institute, Inc, describes how the best managers at Toyota show respect for people:

- Managers begin by asking employees what the problem is with the way their work is currently being done.

- They challenge the employees’ answer and enter into a dialogue about what the real problem is. (It’s rarely the problem showing on the surface.)

- Then they ask what is causing this problem and enter into another dialogue about its root causes. (True dialogue requires the employees to gather evidence from the Gemba for joint evaluation.)

- Then they ask what should be done about the problem and ask employees why they have proposed one solution instead of another. (This generally requires considering a range of solutions and collecting more evidence.)

- Then they ask how they – manager and employees – will know when the problem has been solved, and engage one more time in dialogue on the best indicator.

- Finally, after agreement is reached on the most appropriate measure of success, the employees set out to implement the solution.

“The manager challenges the employees every step of the way, asking for more thought, more facts, and more discussion. This problem solving process actually demonstrates the highest form of respect.

The manager is saying to the employees that the manager can’t solve the problem alone, because the manager isn’t close enough to the problem to know the facts. He or she truly respects the employees’ knowledge and their dedication to finding the best answer. But the employees can’t solve the problem alone either because they are often too close to the problem to see its context and they may refrain from asking tough questions about their own work.

Only by showing mutual respect – each for the other and for each other’s role – is it possible to solve problems, make work more satisfying, and move organizational performance to a higher level.”

References

Womack, James P., Ph.D. “Respect for People.” Letter to LEI. 20 Dec. 2007.Jim Womack’s ELetters & Columns. Lean Enterprise Institute, n.d. Web. 10 Apr. 2015. <http://www.lean.org/womack/DisplayObject.cfm?o=755>.

Henderson, Bruce A., and Jorge L. Larco. Lean Transformation: How to Change Your Business into a Lean Enterprise. Richmond, VA: Oaklea, 1999. Print.

Great post! I really like the focus on the “thinking” behind building a Lean culture. It’s not all about the tools.