Written by Rylie Kostreva

We’re almost half way through the summer, and boy has it been a busy one. We PIC’s like to use the summer months to dive into projects and practice our lean thinking outside of the kaizen realm. This summer we’ve been working on a total of seven projects, all with one center subject, alignment. From better improving our personal task flow, to creating new processes to aid our lean practitioners on campus. We’ve been challenged, and inspired, to take our processes and align each towards one another, as well as to the goals of the Office of Continuous Improvement.

The first lengthy project that we’ve been working on is one that was initiated back in March and has just reached completion. We titled it, “Professional Writing Workshop.” This project was launched after recognizing that all the PICs wrote in a different format and had a different understanding of what “professional” writing meant. On day one we sat down and started our workshop with an affinity diagram, answering the question, “What does professional writing mean?” This helped us to identify our current state, where we all aligned, and where we were different. Then we researched professional opinions on what it actually means to write professionally. From there we evaluated our historical standards, made changes, executed a kata run, and finally decided on a new standard.

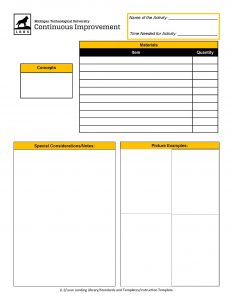

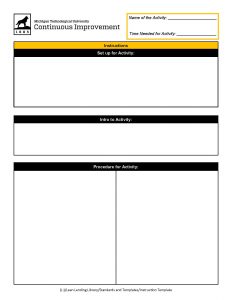

The second project that we’ve been working on as an entire office is the Lean Lending Library. This was initiated back in February and was our first project that strives to practice incremental improvements. This brand new resource is a library of activities. Ones that our office has hosted in the past, and are available to be checked out by other people to host the activity themselves. The library consists of an activity instruction sheet that guides the borrower through the entire activity by providing preparation considerations, materials, and instructions. We completed an inner-office kata run and now we are in the process of having a handful of volunteer facilitators run through a kata.

The third big project that is on-going, is really two that became sisters, PIC board Breakdown and PIC standards. After noticing some disturbances in flow that kept repeating, we decided it was time to reevaluate our PIC processes, these processes were homed by two whiteboards. Dominique and I sat down for a few hours one day and walked through all of the pieces of the board, taking careful note of areas that we identified as being difficult, unclear, or unnecessary. From there we asked, “What items would be better? What things do we do regularly practice that aren’t captured here?” Then we drew up specific things we’d like to add and ideas we wanted to explore. We requested a single, larger whiteboard to create a more friendly canvas and rearranged our board categories into a more thought-out way. The items we look at daily were moved to eye level, our metrics became the center focus, the items we look at monthly moved slightly above eye level, and we created a larger area to note action items. This dissection of flow lead into questioning our current standard practices, and from there we followed a similar process to that of the professional writing workshop and have been working on developing better, more accurate written standards of the PIC duties.

These are just a few of the projects we’ve been working on this summer to create a better experience for the employees and the guests of the office of continuous improvement. Not only has the process become more effective and efficient, but there’s also been an unexpected, yet positive, result from it. Our communication skills amongst one another have increased drastically and our comradery has grown immensely.