I glanced at the caller ID as I answered the phone, but I didn’t recognize the number. The man on the other end introduced himself. He was the president of a small manufacturing plant in Michigan, and he was looking for an engineering intern with a background in manufacturing and Lean experience to manage a Lean project next summer. Could we help him? Yes!

The Office of Continuous Improvement at Michigan Tech is creating an immersive environment for our students to learn about Lean to the mutual benefit of the university, students, employers, and the local community. The university uses Lean in its everyday operations, provides Lean education for students, and coaches students on using Lean in their student organizations and community service. Over the last eight years, Michigan Tech has held over 200 improvement events, all designed to get students in the classroom with calm minds, ready to learn and faculty in their labs with a calm mind, ready to do their research.

Michigan Tech students engage in Lean in many ways. There are several academic courses students can take on Lean principles, Lean culture, and Lean manufacturing, as well as courses on concepts related to Lean, like change management, teamwork, project management, and safety. As a member of the student organization Leaders in Continuous Improvement (LCI), students learn about Lean and practice their skills working with other student organizations and local non-profits. Students have opportunities on campus to attend Lean workshops, take online short courses on Lean principles, request facilitators for improvement events in their student organizations and enterprises, receive coaching on certification preparation, and participate on kaizen as customers or outside eyes. With many departments on campus actively practicing Lean, students with on-campus jobs are exposed to Lean tools and processes like daily huddles, standard work, and visual management. Finally, students encounter and practice Lean during internships and co-ops with industry.

Imagine a world where everyone understands the importance and benefits of quality! Our vision is for every student graduating from Michigan Tech to learn about quality and continuous improvement at some level. We want to meet students where they are at with a full range of engagement possibilities tailored to their unique needs. Look around our website to see how the Office of Continuous Improvement is engaging students, faculty, staff, and the local community in the learning and practice of Lean and continuous improvement. How can industry help? By increasing our students’ awareness of Lean practices in your organization, offering internships that require Lean skills, inviting our students for a tour of your facility or participation in your kaizen, and volunteering as a guest speaker at an LCI meeting.

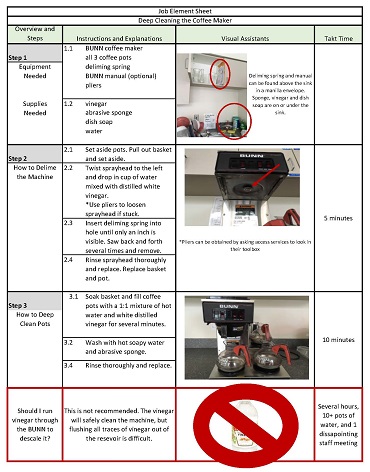

I formatted the job element sheet based on the one used by Catering Services for, coincidentally, making coffee. After picking out the steps involved and taking photos, I realized it would be easy enough to also create a sheet for how to brew a pot of coffee. Maybe it’s my love of the perfect cup of joe, the intimidating nature of a commercial coffee maker, or the fact that it can be difficult for many people to remember how much coffee to use, but for whatever reason I’m also the one who usually makes coffee for staff events. For being such a simple process, I know from experience that there are an outstanding number of ways it can go wrong! I tried my best to draw on this knowledge to help others avoid mistakes like pouring water into the machine without a pot underneath or forgetting to turn the burner off.

I formatted the job element sheet based on the one used by Catering Services for, coincidentally, making coffee. After picking out the steps involved and taking photos, I realized it would be easy enough to also create a sheet for how to brew a pot of coffee. Maybe it’s my love of the perfect cup of joe, the intimidating nature of a commercial coffee maker, or the fact that it can be difficult for many people to remember how much coffee to use, but for whatever reason I’m also the one who usually makes coffee for staff events. For being such a simple process, I know from experience that there are an outstanding number of ways it can go wrong! I tried my best to draw on this knowledge to help others avoid mistakes like pouring water into the machine without a pot underneath or forgetting to turn the burner off.

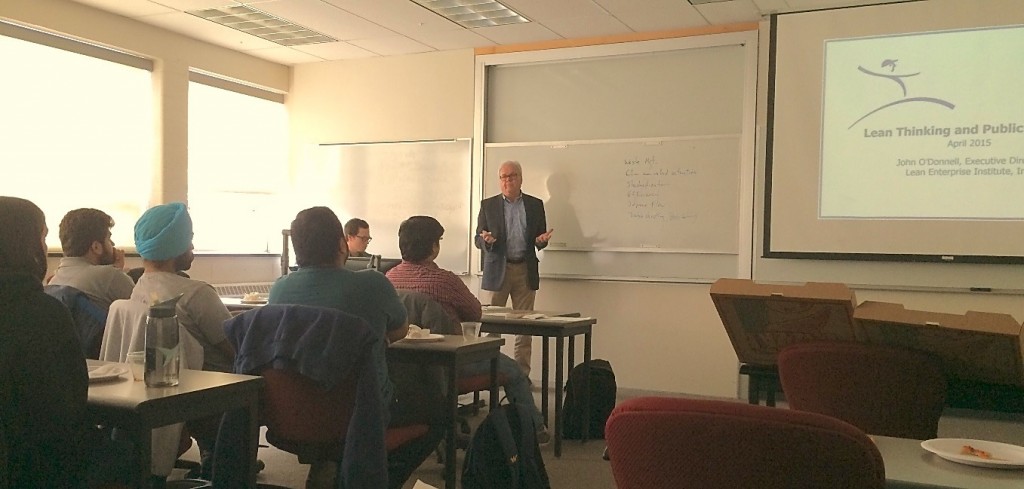

The two Lean fundamentals are respect for people and humility. Respect for people is more than just using your manners. In the workplace, it’s about valuing individuals and their knowledge about how the process actually works, coaching others to develop their problem-solving skills, and solving problems by focusing on the process, not the people. Humility comes when you admit that you don’t know how to solve every problem. This drives you to seek out the ideas of all the people involved in doing the work. Together these fundamentals create a blame-free environment where continuous improvement is the norm.

The two Lean fundamentals are respect for people and humility. Respect for people is more than just using your manners. In the workplace, it’s about valuing individuals and their knowledge about how the process actually works, coaching others to develop their problem-solving skills, and solving problems by focusing on the process, not the people. Humility comes when you admit that you don’t know how to solve every problem. This drives you to seek out the ideas of all the people involved in doing the work. Together these fundamentals create a blame-free environment where continuous improvement is the norm.