The Socratic Method, or Socratic Questioning, is a type of questioning used to encourage critical thinking, analyze assumptions, determine knowns and unknowns, and help stimulate open discussion.

There are six main types of Socratic questions:

- Clarifying the question

- Challenging assumptions

- Evidence as a basis for argument

- Alternative viewpoints

- Implications and consequences

- Question the question

As a student, I have frequently experienced Socratic questioning firsthand in the classroom. Using Socratic questions furthers understanding by helping us as students think more deeply about what we’re learning, challenge the concepts, and be more involved in discussion.

For example, let’s say a professor is explaining an equation used to model a phenomenon; perhaps the flow of blood through a vessel or analyzing the forces acting on an object. Often when modeling a behavior we make assumptions about variables that we can neglect to simplify the equation, and these assumptions can lead to Socratic questions:

- Why are we assuming we can neglect this variable? (Challenging assumptions)

- Can we always neglect that variable? When can’t we neglect that variable? (Asking for evidence as a basis for argument)

- How does that variable affect the model? (Implications and consequences)

- Why is learning this model important? (Question the question).

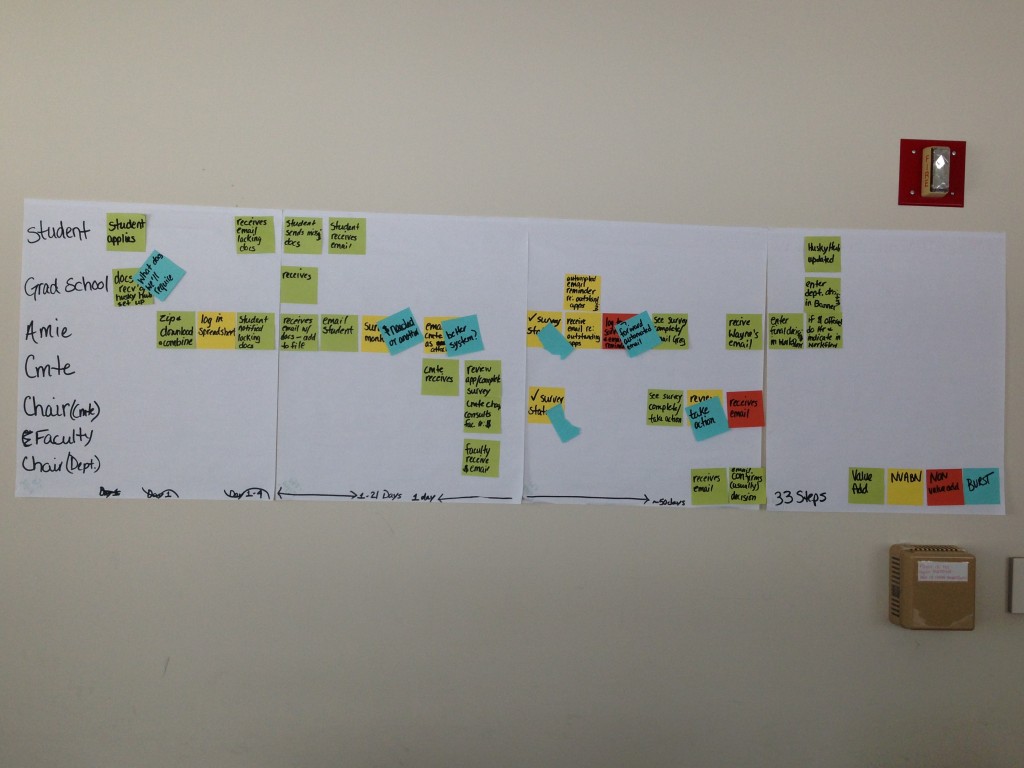

While Socratic Questioning is a useful practice in the classroom, it’s also a great tool for problem solving in Lean processes. Using Socratic Questioning can help a kaizen team with opening up problems, analyzing the process, and engaging in discussion.

(Image from: http://crescentok.com/staff/jaskew/WebBased/questions.htm)

(Image from: http://crescentok.com/staff/jaskew/WebBased/questions.htm)