One of the most important aspects of any workplace is the safety of its workers. When most people think of safety in their workplace they envision long boring safety videos and training every so often, but shouldn’t we empower our workers to want to be safe? This is one of the ways that lean can be brought to safety to further improve it. Actually lean has a lot to offer safety in all of its different aspects.

One of the biggest things lean does to change the environment of safety at the workplace is the safety professionals will treat the workers as their costumers. This is different from the average environment because normally safety professionals will view the upper management or board of directors as their customer. When shifting it from “what does management want in safety” to “what do the workers want in safety”, it allows the workers to have more control of how and what they are learning about safety at their workplace. It enables them to learn in a way they want to, and makes them more apt to be engaged during those training sessions.

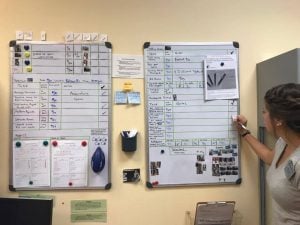

Another way lean changes the environment of safety is it can help to make safety more apparent and visual. This can be done through the use of visual management. By creating visual cues and diagrams of the right and safe way to do something it will give the employees something to refer to and model after. Visual management in this situations also allows anyone who is walking around to determine if the act is right or wrong or safe or not. This allows for anyone to identify an unsafe action and help to correct it before it turns into an injury.

Another aspect that goes along with Visual Management that can improve the safety of workers is the 5S workplace organizational tool. During a 5S, an area or process gets sorted, set, shined, standardized, and sustained. This improves safety in many ways. Some of these ways include the removal of clutter, ensuring spills get cleaned up quickly, having necessary tools close to where they are needed, and the elimination of unsafe practices through standardization. All of these aspects of 5s help to ensure workers are doing their jobs in the safest way possible.

These are just a few ways that lean can change the environment of safety in the workplace for the better. Lean has a lot to offer safety and on the other hand safety has a lot to offer lean. These two concept go hand in hand and when used together can drastically improve the well-being of the workers and the culture of a workplace.