Who doesn’t love spaghetti? It’s one of the most iconic pastas out there! Spaghetti is easy to make and tasty to eat, what could be better? Here at the Office of Continuous Improvement, not only do we like our spaghetti in pasta from, but even more so in diagram form: a Spaghetti Diagram!

Ever do something every day and suddenly realize it takes you way longer than you expected to, or that it took longer than it should? I came to this realization the other day while packing my backpack up to leave for school. I recognized it was taking me 10 minutes to put some binders, pencils, and other common school supplies into my bag, when really it should only take about 5 minutes. I thought what better way to map out my process then a Spaghetti Diagram!

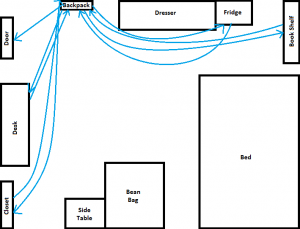

A Spaghetti Diagram is a map that used lines to show the different paths you are taking when you are completing a process. At first glance a Spaghetti Diagram sounds strange and chaotic, but it is actually a very helpful Lean tool. You first map the normal process that you do every day, then you look at the paths that over cross or are unneeded and change them or take them out. This results in a streamlined process. Below you will see my first spaghetti diagram of the steps I take to get my backpack ready on a normal day.

- Open backpack

- Grab supplies such as pens, pencils, and notepads

- Put these supplies into backpack

- Grab books and binders from book shelf

- Put these supplies into backpack

- Grab water bottle and lunch from fridge

- Put those into backpack

- Grab coat and shoes from closet and put them on

- Grab backpack from hook

- Leave for school

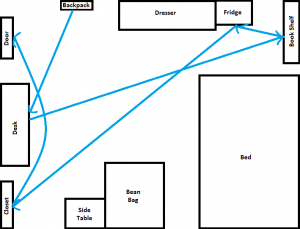

After looking at the diagram and the steps I take every morning, I could see that by carrying my backpack around throughout the process and not returning to it every time I retrieved something to put in it I would save multiple steps. Below is the updated diagram and steps.

- Grab backpack

- Grab supplies such as pens, pencils, and notepads and put them in backpack

- Grab books and binders from book shelf and put them in backpack

- Grab water bottle and lunch from fridge and put them in backpack

- Grab coat and shoes from closet and put them on

- Leave for school

As you can see the steps in the process reduced from 10 to 6, and all I needed was a little help from the Spaghetti Diagram to see the root cause of my problem. By mapping out my steps and the process, all the extra work became visible. This lean tool and many more can be very helpful in situations not only at work but also at home! And who doesn’t love spaghetti?