At the Research Development Day held Jan. 11, 2018, the following individuals were recognized for their research contributions in calendar year 2017.

College of Engineering

Top research expenditures: Jeff Naber (ME-EM), Greg Odegard (ME-EM), Paul Sanders (MSE)

Related:

NASA Taps Tech Professor to Lead $15 Million Space Technology Research Institute

Chemical Engineering

Lei Pan received his first external funding as a principal investigator at Michigan Tech.

Civil and Environmental Engineering

Hui Yao (formerly CEE) received his first external funding as a principal investigator at Michigan Tech.

David Watkins received an award of more than $1 million.

Related:

Household Sustainability: Consuming Food, Energy, Water

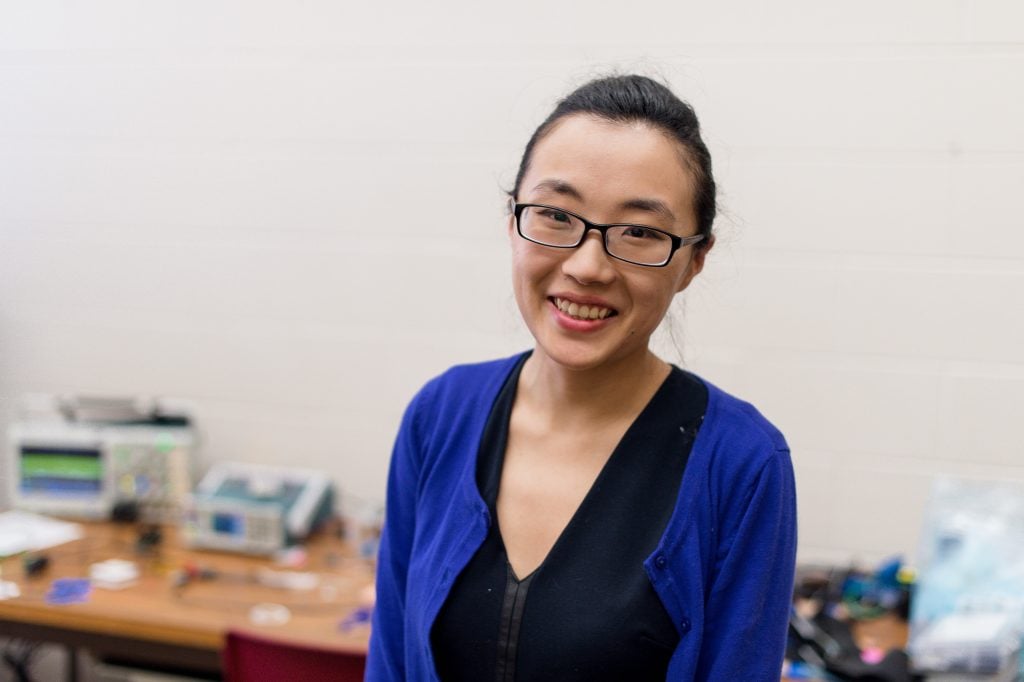

Electrical and Computer Engineering

Jeremy Bos, Lucia Gauchia, and Tony Pinar each received their first external funding as a principal investigator at Michigan Tech.

Geological and Mining Engineering and Sciences

Snehamoy Chatterjee, James DeGraff, Mark Kulie, and Matthew Portfleet each received their first external funding as a principal investigator at Michigan Tech.

Materials Science and Engineering

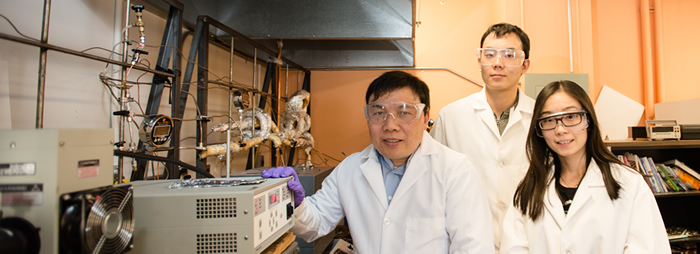

2017 Michigan Tech Research Award: Yun Hang Hu

Bhakta Rath Research Award: Yun Hang Hu and Wei Wei

Joe Licavoli received his first external funding as a principal investigator at Michigan Tech.

Related:

Yun Hang Hu Wins Both Research Award and Bhakta Rath Award

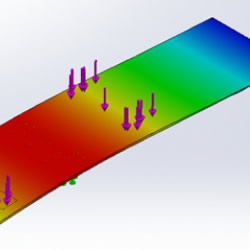

Mechanical Engineering-Engineering Mechanics

Parisa Abadi, Chunpei Cai, Hassan Masoud, and Ye Sun each received their first external funding as a principal investigator at Michigan Tech.

Jeff Naber and Greg Odegard each received awards of more than $1 million.

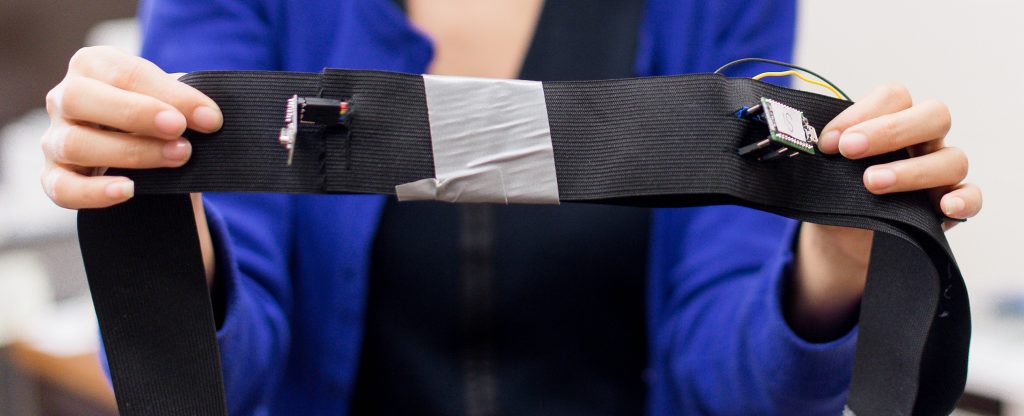

The Fifth Annual Rekhi Innovation Challenge kicked off on Friday Nov. 10, 2017. Three Enterprise teams are competing for funding this year: Blue Marble Security, BoardSport Technologies and Velovations. The Rekhi Challenge is a crowdfunding competition to help promote and support student innovation and entrepreneurship through Michigan Tech’s crowdfunding site, Superior Ideas. The team that raises the most money will receive a monetary match of up to $5,000.

The Fifth Annual Rekhi Innovation Challenge kicked off on Friday Nov. 10, 2017. Three Enterprise teams are competing for funding this year: Blue Marble Security, BoardSport Technologies and Velovations. The Rekhi Challenge is a crowdfunding competition to help promote and support student innovation and entrepreneurship through Michigan Tech’s crowdfunding site, Superior Ideas. The team that raises the most money will receive a monetary match of up to $5,000.

The

The