More than 1,000 students in Enterprise and Senior Design showcased their hard work last Thursday, April 16 at Michigan Tech’s first-ever virtual Design Expo. Teams competed for cash awards totaling nearly $4,000. Judges included corporate representatives, community members and Michigan Tech staff and faculty.

The College of Engineering and the Pavlis Honors College are pleased to announce award winners, below. Congratulations and thanks to ALL teams for a very successful Design Expo 2020. But first, a few important items:

Design Expo Video Gallery

Be sure to check out the virtual gallery, which remains on display at mtu.edu/expo.

20th Anniversary of Design Expo

This year marked the 20th anniversary of Design Expo. Read the Michigan Tech news story here.

Special Note:

In addition to all the Michigan Tech teams, SOAR, a high school Enterprise from Dollar Bay High School in Michigan’s Upper Peninsula, also took part in this year’s virtual Design Expo. Advised by teacher Matt Zimmer, the team designs, builds, and deploys underwater remote operated vehicles (ROVs). SOAR partners with local community organizations to monitor, research, and improve the local watershed. Their clients include Isle Royale National Park, Delaware Mine, OcuGlass, and Michigan Tech’s Great Lakes Research Center. Check out the SOAR video here (SOAR is team 124).

Now, without further ado, here are the Design Expo award results!

ENTERPRISE AWARDS

Based on video submissions

First Place – $500

Blizzard Baja Enterprise

Team Leaders: Olivia Vargo, Mechanical Engineering, and Kurt Booms, Mechanical Engineering Technology

Advisor: Kevin Johnson, Mechanical Engineering Technology

Sponsors: General Motors, Aramco Americas, DENSO, SAE International, Magna, Fiat Chrysler Automobiles, Halla Mechatronics, Meritor, Oshkosh Corporation, Ford Motor Company, John Deere, Nexteer, IPETRONIK, FEV, Milwaukee Tool, Altair, Henkel, ArcelorMittal, TeamTECH, and Keysight Technologies

Overview: Building and innovating a single-seat, off-road vehicle for the SAE Collegiate Design Series-Baja events is the team’s focus. After passing a rigorous safety and technical inspection, they compete on acceleration, hill climb, maneuverability, suspension and endurance. The team also organizes and hosts the Winter Baja Invitational event, a long-standing university tradition dating back to 1981.

Second Place – $300

Mining INnovation Enterprise (MINE)

Team Leaders: George Johnson, Mechanical Engineering; and Breeanne Heusdens, Geological Engineering

Advisor: Paulus Van Susante, Mechanical Engineering-Engineering Mechanics

Sponsors: Cignys, Cummins, General Motors, MEEM Advisory Board, Michigan Scientific Corporation, Michigan Space Grant Consortium, Milwaukee Tool, MISUMI, NASA, Raytheon, Wayland Wildcats

Overview: MINE designs, tests, and implements mining innovation technologies—in some hard-to-reach places—for industry partners. The team is developing a gypsum process to mine water on Mars funded by a grant from NASA. Gypsum is 20 percent water by weight and is found abundantly on the surface of Mars. A geological sub-team is developing methodology for deep sea mining research. Last but not least, MINE is creating a robot for the NASA Lunabotics competition, held every year at the Kennedy Space Center with 50 university teams in attendance.

Third Place – $200 (tie)

Innovative Global Solutions (IGS)

Team Leaders: Nathan Tetzlaff, Mechanical Engineering; Marie Marche, Biomedical Engineering

Advisors: Radheshyam Tewari, Mechanical Engineering-Engineering Mechanics; and Nathan Manser, Geological and Mining Engineering and Sciences

Sponsors: Cummins, Milwaukee Tool, and Enterprise Manufacturing Initiative funded by General Motors

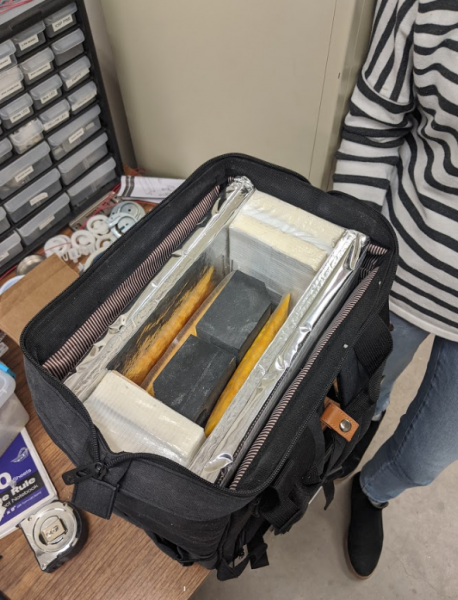

Overview: IGS pursues solutions for the needs of developing countries, making contributions toward solving the Grand Challenges, an initiative set forth by the National Academy of Engineering. The team has designed, built and tested an innovative vaccine container to improve the transport of viable vaccines and increase accessibility. They have developed a low-cost, multifunctional infant incubator to help decrease infant mortality rates. They are also working on an open-source-based 3D printer that can recycle plastic to meet basic community needs.

Third Place – $200 (tie)

Aerospace Enterprise

Team Leaders: Troy Maust, Computer Engineering; and Matthew Sietsema, Electrical Engineering

Advisor: L. Brad King, Mechanical Engineering-Engineering Mechanics

Sponsors: Air Force Research Laboratory, NASA

Overview: Space mission design and analysis, vehicle integration, systems engineering, and comprehensive ground-testing and qualification are all going on within the Aerospace Enterprise at any given time. All members contribute toward achieving specific project goals. The Auris mission demonstrates the technical feasibility of a CubeSat to provide situational data, in collaboration with the Air Force Research Laboratory (AFRL). The Stratus mission involves collecting atmospheric and weather data from a CubeSat in collaboration with NASA—a pathfinder toward developing new, complex space systems leveraging the low-cost and small size of CubeSats to achieve the performance of traditional, monolithic systems.

Honorable Mention – $100

Husky Game Development (HGD)

Team Leaders: Colin Arkens and Xixi Tian, Computer Science

Advisor: Scott Kuhl, Computer Science

Sponsor: Pavlis Honors College

Overview: Developing video games is the name of the game for HGD. Each year, the Enterprise breaks up into subteams of around six students who experience a full game development cycle, including ideation, design, and end product. HGD explores a wide variety of video game engines and platforms, including Windows, Android, Xbox, and an experimental Display Wall.

SENIOR DESIGN AWARDS

Based on video submissions

First Place – $400

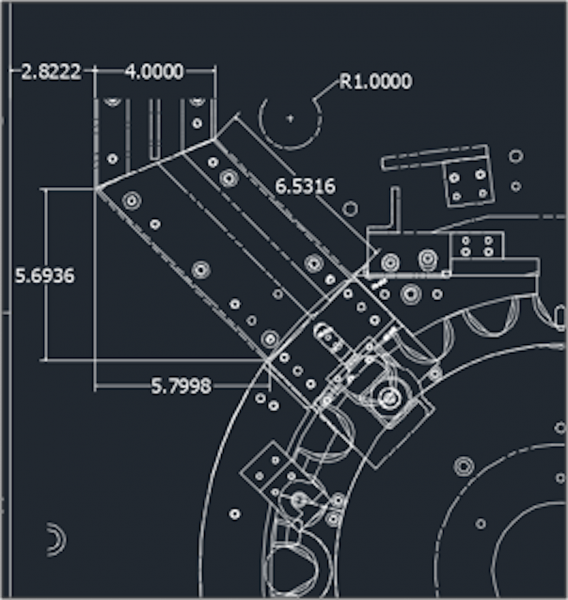

Eddy Current Inspection In-line Integration

Team Members: Brett Hulbert, Austin Ballou, Britten Lewis, Nathan Beining, Philip Spillman and Sophie Pawloski, Mechanical Engineering

Advisor: Wayne Weaver, Mechanical Engineering- Engineering Mechanics

Sponsor: MacLean-Fogg Component Solutions-Metform

Overview: Eddy current testing (ECT) is a non-destructive method for testing metal surfaces for defects using electromagnetic induction to detect surface flaws in conductive materials. The team was tasked with developing an eddy current tester that would non-destructively test a washer for surface cracks and flaws before it is assembled with a nut. They created a testing operation that spins, tests, and ejects washers based on whether they pass or fail, all within the existing assembly cell.

Second Place – $250

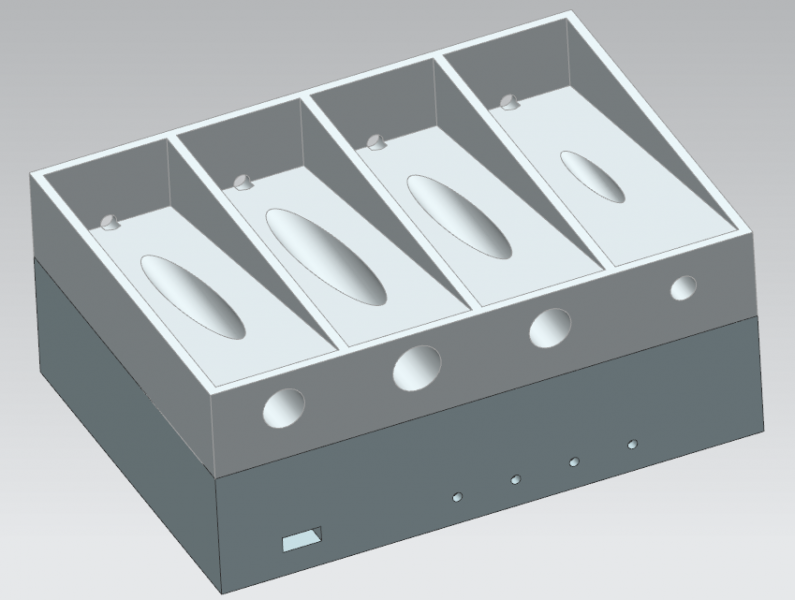

Hospital Washer Auto Sampler Usage & Data Optimization

Team Members: Nick Golden and Jeremy Weaver, Biomedical Engineering; Jack Ivers, Mechanical Engineering

Advisors: Bruce Lee and Sangyoon Han, Biomedical Engineering

Sponsor: Stryker

Overview: Hospitals use wash systems to clean and sterilize instruments after use. Factors of the wash environment can harm surgical instruments. To solve this problem, the team designed a device that actively senses conditions inside a hospital washer to provide information on the effects of the wash environment, allowing for wash cycle optimization.

Third Place – $150

Direct Casting with Additive Manufactured Patterns

Team Members: James Driesenga, Riley Simpson, Camden Miner, Zach Schwab, TC Swittel, and Sean Frank, Mechanical Engineering

Advisor: Bob Page, Mechanical Engineering-Engineering Mechanics

Sponsor: Mercury Marine

Overview: The team developed a lost-foam style casting process that uses a 3D printed pattern instead of expanded polystyrene in metal casting. The use of expanded polystyrene allows for complete part filling, but cost and time required to create a new pattern are high. The 3D printing of patterns eradicates the need for pattern tooling and significantly reduces the time required to produce a pattern.

Honorable Mention (1) – $100

Radiofrequency Ablation Modeling and Validation of Cannula Designs

Team Members: Clare Biolchini, Matthew Colaianne, and Ellen Lindquist, Biomedical Engineering; Samuel Miller, Electrical Engineering

Advisor: Jeremy Goldman, Biomedical Engineering

Sponsor: Medtronic

Overview: Predictable lesion formation during radiofrequency (RF) ablation for pain control is a function of many factors and the subject of decades of research. Of specific interest to Medtronic is lesion formation in non-homogeneous tissues and structures. The team developed mathematical models and physical model validation for treatment scenarios, including knees and shoulders. Photo courtesy of Medtronic.

Honorable Mention (2) – $100

Airport Needs Design Challenge

Team Members: Derek Cingel, Jared Langdon, Bryce Leaf, Ruth Maki, and Douglas Pedersen, Mechanical Engineering

Advisor: Paul van Susante, Mechanical Engineering-Engineering Mechanics

Sponsor: Airport Cooperative Research Program

Overview: To help reduce the contamination of deicing fluid in small airports, the team developed a cart specially designed to collect a significant amount of the fluid that comes from the wings. Saving and reusing deicing fluid will save money, and reduce the runoff into streams and waterways.

Honorable Mention (3) – $100

Validation Test System for Boston Scientific IPP

Team Members: McKenzie Hill, Ahmed Al Dulaim, Nathan Halanski, and Katherine Wang, Biomedical Engineering

Advisors: Orhan Soykan and Sangyoon Han, Biomedical Engineering

Sponsor: Boston Scientific

Overview: Performing analyses, simulations, and engineering calculations, the team was able to estimate and predict the movement of IPP cylinders and resulting stress/strain. They designed new test procedures to perform physical testing and fabricated a physical test system.

Honorable Mention (4) – $100

Road Marking Reflectivity Evaluator

Team Members: Brian Parvin, Mechanical Engineering; Paul Allen, Electrical Engineering; and David Brushaber, Kurtis Alessi and Alex Kirchner, Computer Engineering

Advisor: Tony Pinar, Electrical and Computer Engineering

Sponsor: SICK, Inc.

Overview: When road stripes wear off, auto accidents increase. To solve this problem, the team developed software that uses reflectivity values obtained using a SICK lidar unit. Their new software identifies deterioration of road stripes and recommends timely repainting, which will also aid in the safety and reliability of self-driving vehicles on roadways. The team constructed a prototype to demonstrate functionality–a pushable cart that evaluates road markings. An intuitive user interface displays the markings being evaluated, and indicates if they meet necessary levels of reflectivity. With their project, the team is taking part in the TiM$10K Challenge, a national innovation and design competition.

20th Anniversary “People’s Choice” Award – $100

Based on receiving the most text-in votes during Design Expo

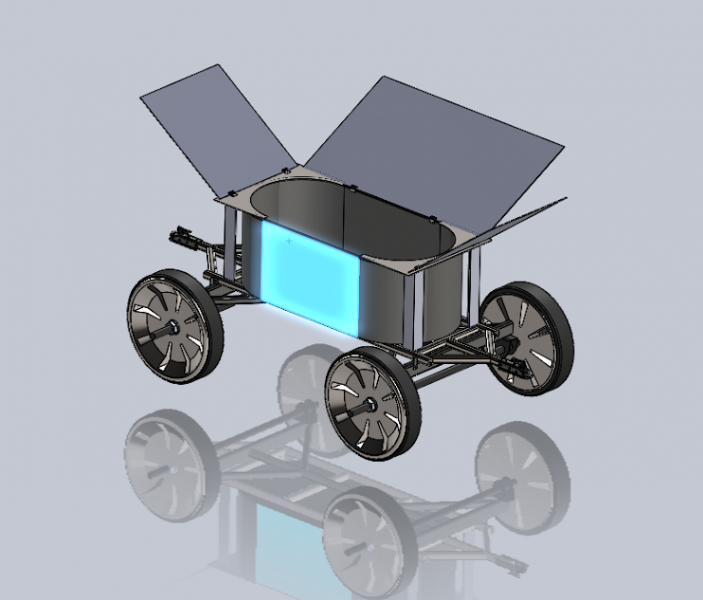

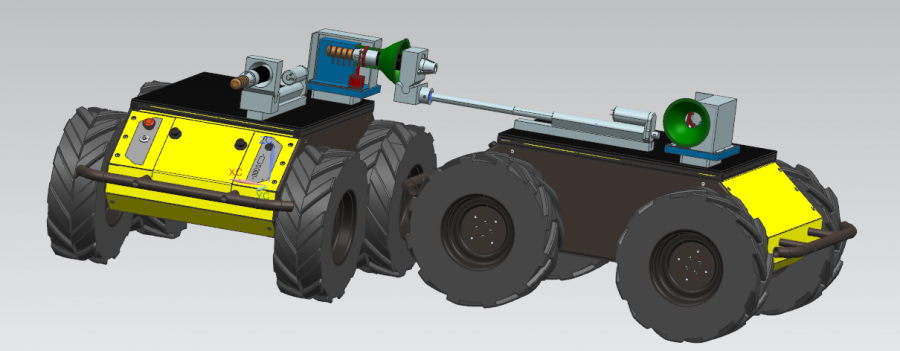

Connector and Coupling Actuator for Mobile Electrical Microgrids

Team Members: Trevor Barrett, Nathan Bondi, and Sam Krusinski, Mechanical Engineering; Travis Moon, Electrical Engineering

Advisor: Cameron Hadden, Mechanical Engineering-Engineering Mechanics

Sponsor: Center for Agile and Interconnected Microgrids

Overview: Imagine how someone living through a natural disaster like Hurricane Katrina or Hurricane Dorian must have felt—scared and helpless, with no way to call for assistance or let loved ones know they were okay. It could be days or weeks before first responders are able to restore power to the area. That is where our project comes in. Our team was tasked to design, prototype, and test a connector and coupling actuator that can establish an electrical connection between two unmanned ground vehicles that will be used to build temporary microgrids in areas that desperately need it.

DESIGN EXPO IMAGE CONTEST

Based on team photos submitted during Design Expo registration

First Place – $200

Formula SAE Enterprise

Second Place – $100

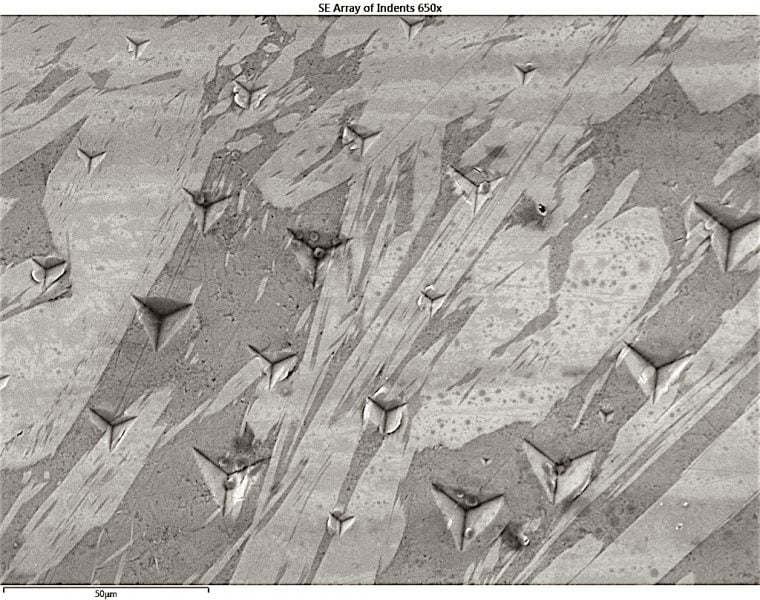

Flammability Reduction in Magnesium Alloys for Additive Manufacturing

Third Place – $50

Velovations Enterprise

DESIGN EXPO INNOVATION AWARDS

Based on application. Learn more here.

First Place – $250

Increasing the Young’s Modulus of Cast Aluminum for Stiffness-Limited Applications

Team Members: Joel Komurka, Ryan Lester, Zeke Marchel, and

Wyatt Gratz, Material Science and Engineering

Advisor: Paul Sanders, Materials Science and Engineering

Sponsor: Eck Industries

Second Place – $150

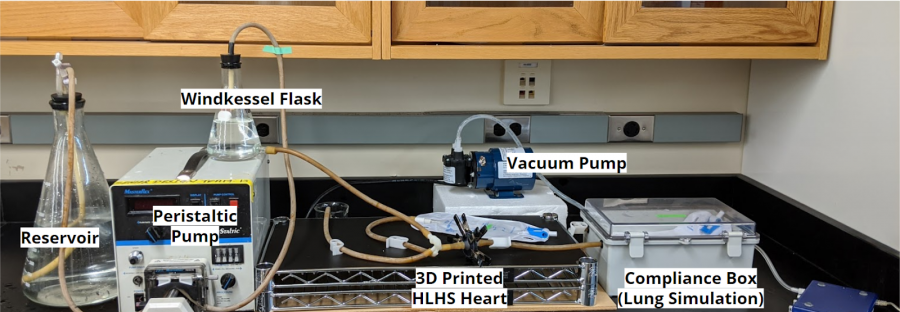

Transcatheter Sign Ventricle Device (BME)

Team Members: David Atkin, Kelsey LeMay, and Gabrielle Lohrenz, Biomedical Engineering

Advisors: Smitha Rao and Jeremy Goldman, Biomedical Engineering

Sponsor: Spectrum Health—Helen DeVos Children’s Hospital

Third Place – $100

Innovative Global Solutions (IGS)

Team Leaders: Nathan Tetzlaff, Mechanical Engineering; Marie Marche, Biomedical Engineering

Advisors: Radheshyam Tewari, ME-EM and Nathan Manser, Geological and Mining Engineering and Sciences

Sponsor: Enterprise Manufacturing Initiative funded by General Motors, Cummins, Milwaukee Tool

2020 ENTERPRISE AWARDS

Based on student, advisor, faculty and staff nominations.

Student Awards

Outstanding Leadership: Allysa Meinburg, Consumer Product Manufacturing

Rookie Award: Bryce Traver, Alternative Energy Enterprise

Innovative Solutions: Travis Wavrunek, Alternative Energy Enterprise

Industry/Sponsor Relations: Jordan Woldt, Blue Marble Security/Oshkosh Baja Suspension Team

Faculty/Staff/Sponsor Awards

Outstanding Enterprise Advisor: Dr. Tony Rogers, Consumer Product Manufacturing

Outstanding Enterprise Sponsor: Michael Bunge, Libbey Inc.

Behind the Scenes: Steven Lehmann, Biomedical Engineering

THANKS TO ALL!

Now, be sure to check out all the awesome Enterprise and Senior Design team projects at mtu.edu/expo.