The Michigan Tech Alumni Board of Directors is proud to recognize outstanding alumni and friends with their 2021 awards program. The following are engineering alumni recognized this year:

Outstanding Young Alumni Award

Presented to alumni under the age of 35 who have distinguished themselves in their careers. The award recognizes the achievement of a position or some distinction noteworthy for one so recently graduated.

Electrical Engineering

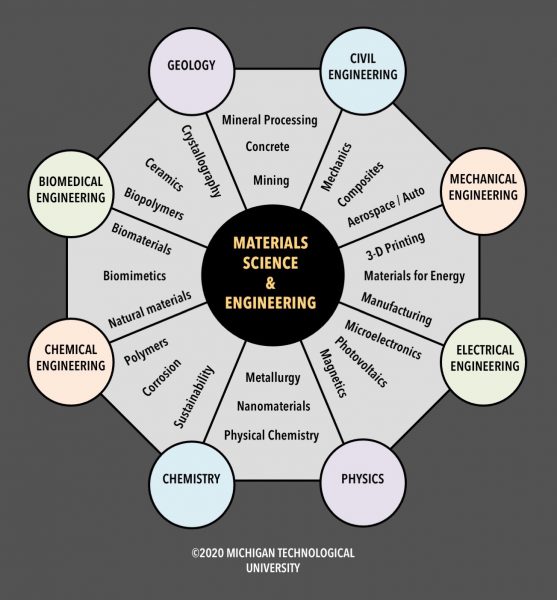

Mathematics and Materials Science and Engineering

Outstanding Service Award

Presented to alumni and friends making significant contributions to the success of the Board of Directors and/or the University.

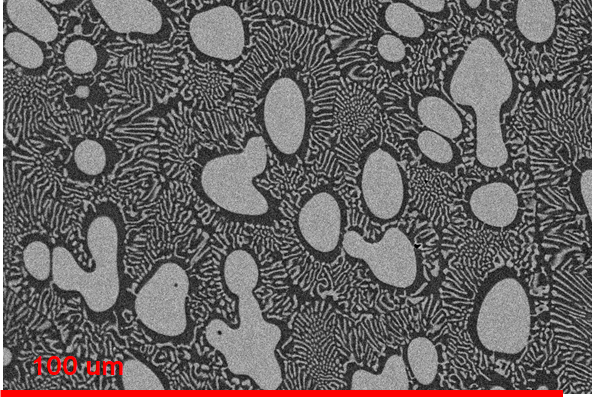

Metallurgical Engineering

Distinguished Alumni Award

Presented to alumni who have made outstanding contributions both in their career and to Michigan Tech over a number of years.

Chemical Engineering