We are pleased to present this guest blog post by Heather Dunne, Digital Services Specialist for University Marketing and Communications at Michigan Technological University.

One of the common tools in Lean and continuous improvement is error proofing, or poka-yoke. Poka-yoke is a Japanese term that was developed and classified by Shigeo Shingo; that helps someone avoid (yokeru) mistakes (poka).

The concept is simple: Create countermeasures that guard against and prevent errors and mistakes from occurring in a process. If mistakes are avoided, the product quality is high, the customer is happy, and money is saved. Workers, engineers, and managers all must work together to write procedures and design devices to prevent errors from occurring at their source. Errors made within any process can lead to problems, including multiple wastes such as defects, overproduction, waiting, not utilizing people, transportation, inventory, motion, and excess processing.

Error proofing is implemented to prevent human error, but human error cannot be accepted as the cause of an error. The blame game does not apply. Humans make mistakes typically because there is a flaw in the process, itself. There are standard steps that can be taken when error proofing a process. First, take a first-hand look at the process, walking the gemba. Secondly, learn exactly where the error occurred. Then, conduct some problem solving analysis to uncover the root cause. Finally, develop countermeasures to prevent that error from happening again.

Some examples of real-world poka-yokes are the sensor in the gas nozzle that clicks when your tank is full, the ice maker in your freezer shutting off when the bucket if full, and your washing machine stopping when it is out of balance.

Michigan Tech’s Housing and Residential Life developed some poka-yokes for summer conferences:

- A reference visual for staff who are setting up linens for a room. It lists exactly what linens are needed and shows how they should be placed on the bed. This saves staff time when gathering linens to distribute and reduces error in forgetting to place an item in the room.

- Signage informing guests about areas they have access to and areas they do not. Limiting access to certain floors used the ERA principle–Eliminate Replacement Alternatives. If the task that is creating the error is eliminated, then the error will disappear too.

- A kanban board for management of the many groups that stay as guests. By arranging items, information, and people according to a sequence, they developed a good mistake proofing solution.

What are some ways you can apply this simple lean concept in your area?

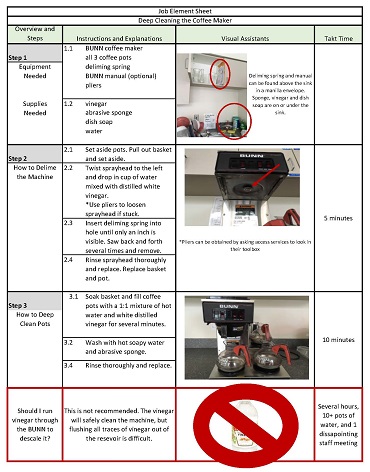

I formatted the job element sheet based on the one used by Catering Services for, coincidentally, making coffee. After picking out the steps involved and taking photos, I realized it would be easy enough to also create a sheet for how to brew a pot of coffee. Maybe it’s my love of the perfect cup of joe, the intimidating nature of a commercial coffee maker, or the fact that it can be difficult for many people to remember how much coffee to use, but for whatever reason I’m also the one who usually makes coffee for staff events. For being such a simple process, I know from experience that there are an outstanding number of ways it can go wrong! I tried my best to draw on this knowledge to help others avoid mistakes like pouring water into the machine without a pot underneath or forgetting to turn the burner off.

I formatted the job element sheet based on the one used by Catering Services for, coincidentally, making coffee. After picking out the steps involved and taking photos, I realized it would be easy enough to also create a sheet for how to brew a pot of coffee. Maybe it’s my love of the perfect cup of joe, the intimidating nature of a commercial coffee maker, or the fact that it can be difficult for many people to remember how much coffee to use, but for whatever reason I’m also the one who usually makes coffee for staff events. For being such a simple process, I know from experience that there are an outstanding number of ways it can go wrong! I tried my best to draw on this knowledge to help others avoid mistakes like pouring water into the machine without a pot underneath or forgetting to turn the burner off.