Prasad Soman will graduate soon with his PhD in Materials Science and Engineering. But instead of walking down the aisle and tossing his cap in Michigan Tech’s Dee Stadium, this year he’ll take part in Michigan Tech’s first-ever outdoor graduation walk.

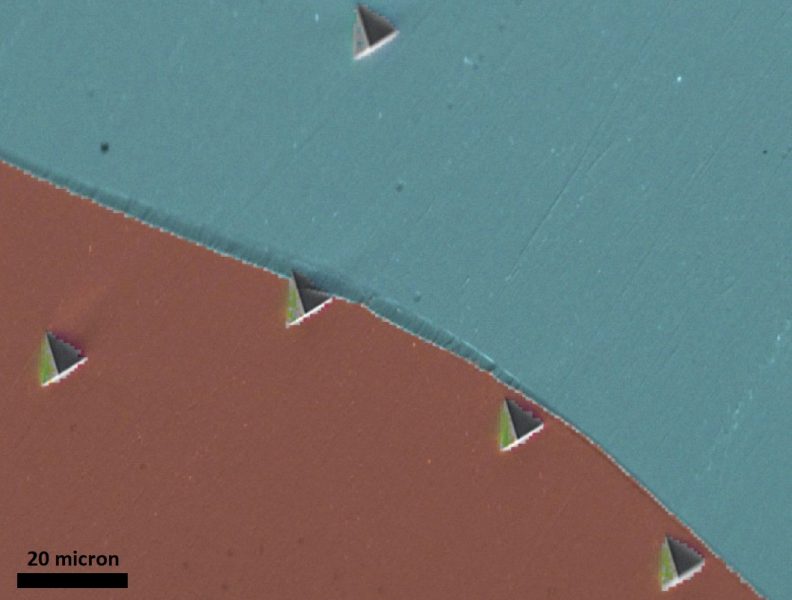

“My PhD research goal was to better understand how the addition of carbon affects the strengthening mechanism of iron—by looking to see what happens at the nanoscale,” he explains.

Soman studied the mechanisms of grain boundary strengthening by using an advanced and challenging technique known as nanoindentation to get “up close and personal” to the interfaces between individual crystals within a material. Just last week Soman successfully defended his PhD dissertation: “Study of Effects of Chemistry and Grain Boundary Geometry on Materials Failure.” The research was sponsored by the US Department of Energy.