This past week Theresa Coleman-Kaiser was informed that she will be a Greenbelt Coach for the third cohort of State of Michigan employees to go through a Lean Greenbelt certification program. She volunteered through the Michigan Lean Consortium. From a press release on May 20th, 2013, “Good Government is about achieving best-in-class public service through empowered and innovative employees. Elements of good government are service and process optimization, employee engagement, change management, and performance management.” Below is a video clip of Lt. Governor Brian Calley at the project orientation in June of 2012.

Hello Michigan Tech Staff and Faculty,

If you are interested in expanding your continuous improvement knowledge, consider checking out a book from the “Lean Library“, located in the Continuous Improvement Office .

At the end of April I was part of a project to 5S a shelf in the MUB kitchen. The blog post for the first shelf can be found here. The next step at the time was to do the same process to a similar shelf of catering platters and trays.

Initially we were going to simply 5S the second shelf. However, after some discussion during the Sort phase we realized that it might be worthwhile to take a look into what was truly value-add that should remain on the shelf. Originally there were two levels of platters and trays. One called “copper” and the other called “silver.” The copper level of service consisted of plastic items. These platters and trays were prone to being scratched and losing aesthetic appeal, therefore requiring frequent replacement. The silver level of service, though more expensive, did not require as frequent replacement.

We began asking why we had two levels of service. At first we thought that having two levels of service gave the customer options and control over what their food was served on. However, it was found that very rarely did anybody request the plastic level of service. After performing this informal 5 Why exercise we decided to standardize from two levels to just the silver. This resulted in

- Decreasing inventory (increasing shelf space, decreasing capital invested in non-value add items)

- Improving flow in other catering processes

- Eliminating the risk of customers having a poor experience with plastic platters and trays

How many meetings do you go to each week? What percentage of your typical day is tied up in meetings? Are these meetings adding value to your work and to your customers? Lean practice is about eliminating waste, non-value adding activities. Since knowledge based work and service driven processes seem to require more meetings than a manufacturing environment it is important to identify the value of a meeting as a lot of waste can be hidden within them. Here are some tips to help you hold a effective and valuable meeting:

- Identify the purpose of the meeting and why it needs to be held.

- Identify what objectives or decisions need to be met in the meeting.

- Create a schedule that includes the meeting purpose, objectives and decisions to share with those invited. This does not have to be a formal agenda, it can simply be within an email of invitation request.

- Determine the length of the meeting based on it’s purpose and objective. Schedule shorter or longer increments of time, do not feel fixated on the one hour meeting.

- Stick to the meeting agenda and record follow-up tasks and action items that are a result of discussion.

- Relay decisions made and assign the follow-up tasks and action items at the end of the meting so that all attendees know what is expected at the meetings close.

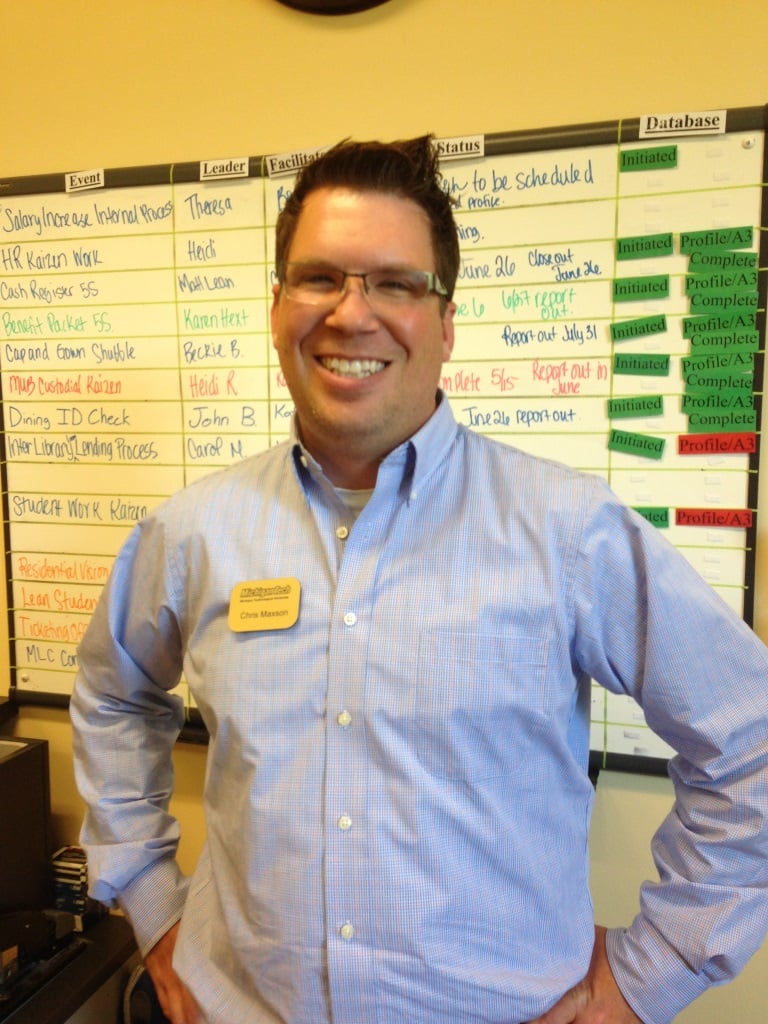

Chris Maxson has joined the Office of Process Improvement as an interim manager and will be assisting the office through September. Chris serves as the Skier Services Manager for Mont Ripley, which is owned and operated by Michigan Tech. Previous to MTU, Chris worked as a robotic technician on a start-up team for a company with a deeply rooted culture of continuous improvement.

Here Chris will introduce himself and share some thoughts about his new role:

By this time of the year, normally my work at Mont Ripley has drawn to a close and I’m off to some summer adventures before getting back to work in the fall. But this summer I’ve been given an exciting opportunity to work with Michigan Tech’s Office of Continuous improvement as interim manager. I have always enjoyed assisting with improvement projects, so a summer to continue my Lean journey will be great.

I have been getting the question, what is the Office of Continuous Improvement? What do they do? The first time I got this question, I thought the answer was obvious. I mean, we help us all work better, right? But after the fifth question, I began to wonder: wait, what does the Office of Continuous Improvement really do?

As it turns out, we not only improve processes; we are in the empowerment business. The role of Continuous Improvement is to share knowledge and spirit with the students, faculty, and staff of Michigan Tech, placing them on a path of eliminating extra, unnecessary steps in processes making room for more capacity and value every day for all of us. Michigan Tech’s Office of Continuous Improvement is an investment into its true assets, its people.

Last week I was involved in a kaizen event that was organized to counteract problems within the ordering and distribution of caps and gowns for graduation. Issues the team worked through were the logistics of the sporadic influx of inventory (40-60 large boxes that flood the inventory space twice per year) and the long lines customers dread to obtain their cap and gown. One important concept I learned from this kaizen was the importance of going to the gemba. To fully understand the issues and problems, we found ourselves taking many trips to the gemba – the place where the work happens.

As noted by Wikipedia, problems are visible at the gemba, and the best improvement ideas will come from going to the gemba. For this kaizen, we spent some time in the inventory room of the Michigan Tech Campus Bookstore to take a look at the current situation. The picture below shows discussion during one of our gemba visits (note the large boxes that don’t even fit on the shelf). Each time we went to the inventory room we were better able to understand the limitations of the space and brainstorm countermeasures.

“Gemba walks” are not just for kaizen events. Ideally they should be done as often as possible to provide supervisors and management with a true picture of what workers are experiencing on a day-to-day basis. Mark Graban, a lean consultant with a focus on healthcare, recently wrote about an article by Delos Cosgrove, President and CEO of Cleveland Clinic, and his experience with going to the gemba. These walks are not only important in industries or businesses with physical inventory such as manufacturing, merchandising, or healthcare. In a knowledge-based industry it is still effective to go to the place where work is being done on a regular (though unscheduled) basis to “go see, ask why, [and] show respect.”

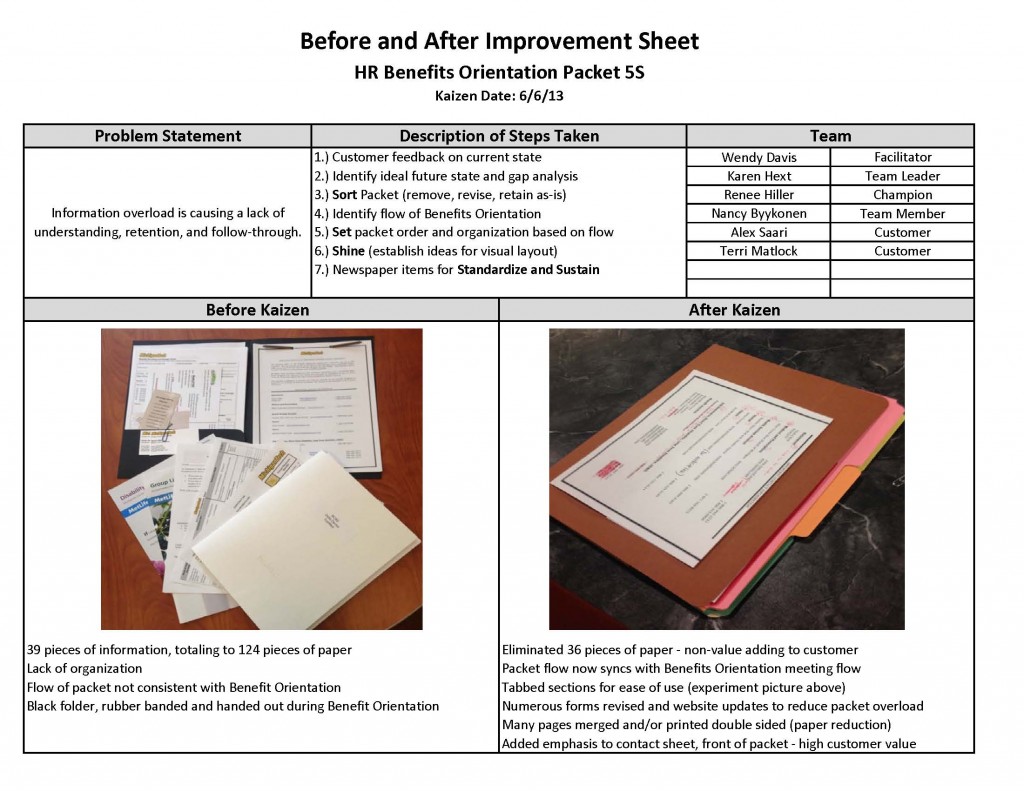

A short improvement event (utilizing 5S methodology) occurred today to solicit feedback from recently hired employees on the value adding (and non-value adding) items in the Benefits Orientation Packet. The packet is designed to provide resources for new staff to make decisions on benefits such as medical, dental and vision insurance, retirement, etc. The packet has collected information and resources over time and through many benefit changes – which has resulted in a lack of organization, duplicate and redundant information, and non-value added information to the customers. Check out the Before and After sheet of the improvements the team made in just a few short hours.

A recent kaizen event addressed a couple problems in residential dining: unauthorized access into the dining halls, and theft of food and utensils. One tool that we used to drive each day’s discussion was a Fishbone Diagram. After determining what was currently happening in contrast to an ideal state, a fishbone diagram was created to understand what problems stood in the way of reaching the future state.

The team brainstormed these problems and listed them on the diagram under headings (see picture below). The diagram aided in creating good discussion and exploration of the problem, the team members were able to piggy-back ideas that related to each other.

After the brainstorming cooled down and the team felt the diagram was complete, various techniques were used to prioritize the issues to see which ones will be tackled and in what priority. Common themes easily emerged showing where the team should focus their efforts. At the end of the kaizen event the team had a clear understanding of the problem, its causes, and where to go with countermeasures to improve the problems.

Former Michigan Tech Lean consultant, Mike Taubitz, is featured in a podcast on Leanblog.org. Check it out HERE!

Last week, I was fortunate to be granted the opportunity to participate in an improvement event at ThedaCare in Appleton, Wisconsin. I was a “fresh eyes” participant on a team that was looking to make improvements in the outpatient lab scheduling process at ThedaCare hospitals. As someone who has interests in both healthcare and Lean, participating in this event was a fantastic opportunity to see firsthand how the two work together.

The biggest “a-ha!” moment I had during my week at ThedaCare was the use of a SIPOC Process Map. I only had a vague understanding of what SIPOC was and did not really know the value or purpose of the tool prior to this event. The SIPOC map, in addition to showing the suppliers, inputs, process, outputs, and customers, identifies the “trigger” for the process to start and the signal that the process is complete.

A SIPOC map can be used to provide a high-level overview of the process and define the scope. The well-defined “trigger” and “done” signals in a SIPOC map help prevent “scope creep” from occurring. “Scope creep,” is when the team widens their improvement discussion beyond the goals of the project. In the ThedaCare kaizen event, any issues the team identified that were outside of the scope (not on the SIPOC diagram) were put into an Out of Scope Parking Lot for future referral. This allowed the team to focus on our scope, but ensured that the other ideas for future improvements wouldn’t be lost.