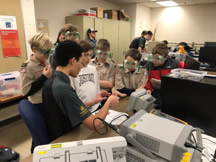

Shane Oberloier (ECE), Ian Raymond (HU) and undergraduate student William Forney (robotics engineering) were quoted by the Daily Mining Gazette in a story about the 2024 Maker Fest, held March 23 at Houghton High School. This was the second year for the event, put on by Superior Fab Lab.

“It’s the chance to show off the tools we use in the enterprise, show how they can be used and generate interest in it that way.”

The event celebrated the process of making and offered nearly 30 hands-on activities. Raymond let visitors engage in stop-motion filmmaking. Forney, an Open Source Hardware Enterprise member, offered 360-degree 3D scans of people’s heads. Also mentioned was the Society of Women Engineers, which ran a booth on building paper circuits.

Read more at the Daily Mining Gazette, by Garrett Neese.

Michigan Technological University’s

Michigan Technological University’s