After a volcanic eruption, it can take years for vegetation to recover, and landscapes are often forever changed. But well before any eruption takes place, the assemblage of plant species on and around the volcano show signs of stress, or even die off.

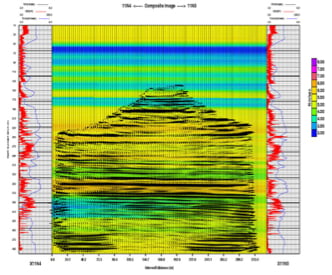

Chad Deering, a volcanologist in the Department of Geological and Mining Engineering and Sciences at Michigan Technological University uses hyperspectral remote sensing data, acquired during an airborne campaign over Hawaii, to predict future volcanic eruptions on the Big Island. Deering and his team of graduate students from Michigan Tech are collaborating with scientists from the NASA Jet Propulsion Laboratory (JPL), and the University of New Mexico.

“The replenishment of a shallow magma reservoir can signal the onset of an eruption at a dormant volcanic system, such as at Mauna Loa. It can also indicate significant changes in eruptive behavior at an already active volcano, as in what occurred at Kīlauea,” Deering says.

“Rising magma ultimately results in a flux of volatiles through the ground, including carbon dioxide and sulfur dioxide. Active vent plumes of those same gases include particulate matter, even thermal energy, and those often enter the atmosphere, as well. “

By detecting and characterizing those fluxes and their effects on the health and extent of local vegetation, Deering is able to recognize significant changes in a volcano’s behavior. The result: a new, cost-effective way to forecast volcanic hazards and events.

“Monitoring vegetative stress on a volcano can potentially provide a much-needed early warning system for those living near and around volcanoes,” adds Deering. An estimated 500 million people are living in danger zones around the world.

“Our preliminary results indicate a strong correlation between emissions of carbon dioxide and hydrogen sulfide gas from soil—as well as the thermal anomalies—and different aspects of vegetative stress.”

Deering’s team uses highly sensitive hyperspectral analysis to distinguish between effects of different gas species and thermal anomalies on variations in vegetative stress. “This is important as CO2 and H2S have different solubilities in magma. That allows us a semi-quantitative measure of the depth of magma as it rises.

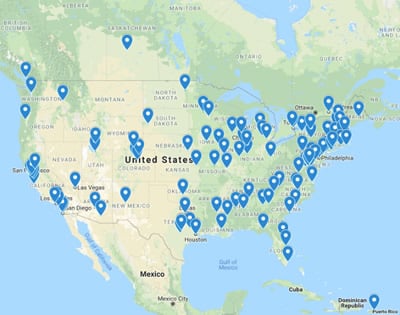

With the results of their study, the team developed a remote-sensing automated detection algorithm that can be used in satellite-based platforms to detect volcanic unrest at volcanoes worldwide.

“In particular, this tool will allow the scientific community to monitor volcanoes that are otherwise inaccessible due to heavy vegetation and/or their remote locations,” adds Deering. “It will also remove technical barriers such as establishing extensive and expensive seismic arrays that are difficult to maintain.”

NASA gathered the hyperspectral data over the course of a year, starting in 2017. Deering and his team are now analyzing more recent data, collected last year. “We want to determine whether we could have predicted the recent volcanic fissure emergence and activity taking place in Hawaii.”

A total of 48 nominations have been submitted for the 2019

A total of 48 nominations have been submitted for the 2019