A Note from the Chair

I hope you have stayed healthy and safe during these unusual times.

Spring has finally arrived at the Keweenaw after a long winter! As the cycle of Nature starts anew, so too does the process of regular Departmental Newsletters. This newsletter reaches you after a long hiatus, but the dormancy does not mean that progress ceased behind the scenes; on the contrary, we have been keeping busy, and many new exciting developments have occurred.

Any attempt to recap all the news and excitements over the last decade in a single letter would be impossible, so I encourage you to visit our Departmental News blog to read more about the achievements of our faculty, students, and staff in research and education. You may also want to check out our faculty and staff directories to see some new and not-so-new faces and learn more about our people and their activities.

An achievement that cannot go unmentioned is the reinstatement of our Bachelor of Science in Mining Engineering program in 2019. This success came through the dedicated and indefatigable efforts by Professor John Gierke, who served as department chair from 2014 to 2020, and our superb mining engineering faculty, Associate Professor Snehamoy Chatterjee and Senior Lecturer Nathan Manser (an MTU alumnus BSME ‘01), who joined the Department in 2014 and 2018, respectively. Several faculty from outside the department generously contribute their expertise in the education of our mining engineering students. I am delighted to report that, in spring 2020, we celebrated our first graduating class of mining engineers since 2004!

Our faculty and staff have worked tirelessly to keep our department moving forward positively through the global pandemic crisis. Our achievements and the success of remote and socially distanced learning and research are sources of pride for the department and the wider GMES community. Despite unprecedented challenges, our students and faculty performed extraordinarily well, especially since experiential geology learning is not easily amenable to virtual instruction. Their flexibility, resourcefulness, and perseverance have been exemplary.

Also deserving of praise are our 2020 and 2021 graduates and the student recipients of recognitions and awards.

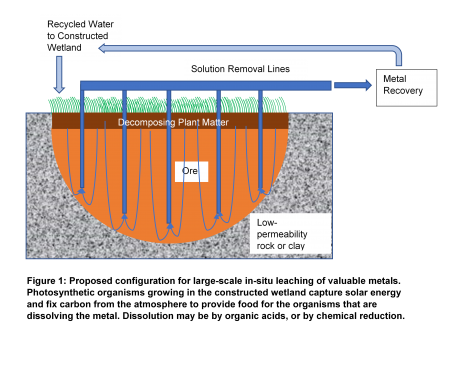

Our faculty and research scientists have stayed very active in cutting-edge and societally relevant research, collaborating around the globe and providing hands-on, real-world experience for our students.

Many of these achievements have been possible only with your continuing support, encouragement, and interest in our efforts and accomplishments.

Your impact on the world is a great motivator for our students.

On behalf of our students, faculty, and staff, I would like to express my deepest gratitude to our alumni and friends who have donated to our department; this support has allowed us to keep offering the best instruction and resources to our students during these difficult times.

One of my overarching goals as chair is to maintain and expand a strong and committed alumni base. If you are ever back in town, I hope you will stop by to say hello and share your story. In the meantime, please don’t hesitate to email me any time at asmirnov@mtu.edu, or use this link to share your successes and achievements or offer suggestions. Your impact on the world is a great motivator for our students.

Finally, I invite you to stay connected to the department via Twitter, Instagram, Facebook, and our website.

Best wishes,

Aleksey Smirnov