MMET Lecturer Kevin Johnson and MMET Department Chair John Irwin teamed up to raise funds to enhance fluid power offerings in the MMET department, with great success.

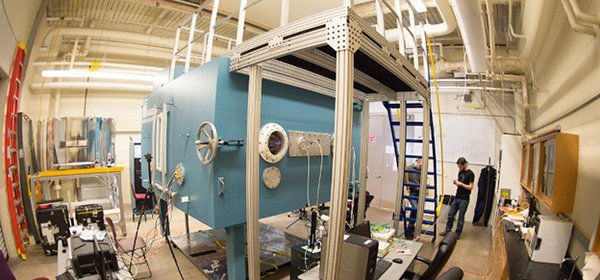

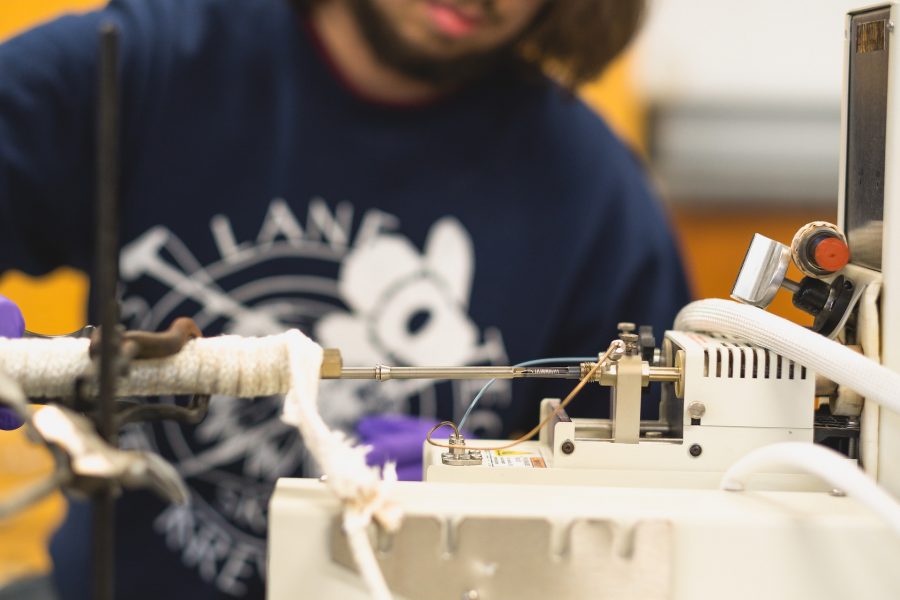

The two were awarded generous grants from the National Fluid Power Association (NFPA) and from the Parker-Hannifin Foundation to develop curriculum and provide hydraulic equipment to support the department’s Parker Motion and Control Laboratory at Michigan Tech.

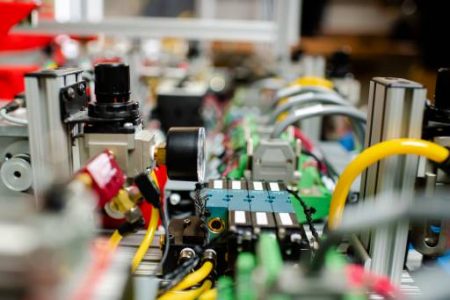

There are two fluid power courses available for MET and/or Mechatronics students at Michigan Tech. Those are MET4377 – Applied Fluid Power, and MET4378 – Advanced Hydraulics: Electro- hydraulic Components & Systems. “The second course incorporates Industry 4.0 concepts used in automated manufacturing,” notes Irwin.

“There is an emphasis in the MMET department to incorporate Industry 4.0 concepts in the curriculum,” he adds.

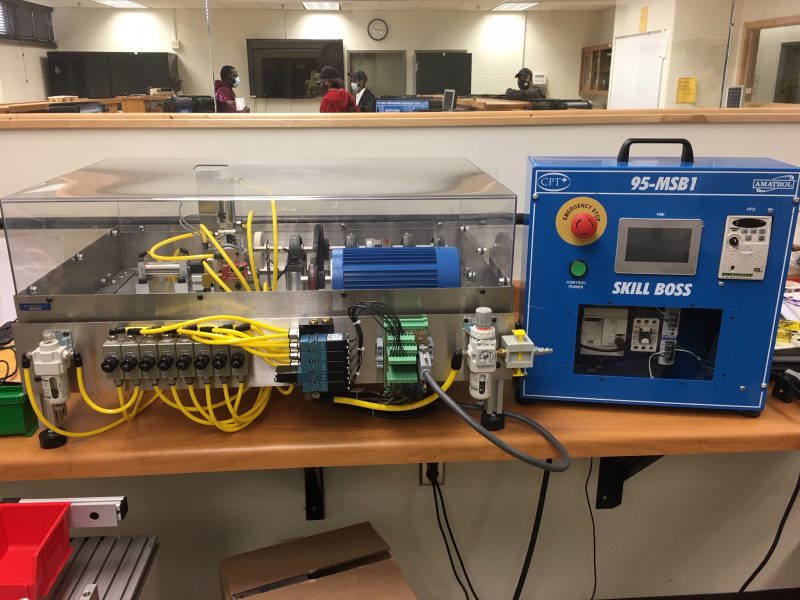

“The MMET department is cooperating with Michigan Tech’s College of Computing to teach MS Mechatronics courses, utilizing the Electrical Engineering Technology (EET ) PLC and Robotics lab. Another example of this synergistic partnership is the delivery of a new Career and Technical Education course in Mechatronics offered by the MMET department for high school juniors and seniors. Implementation of this program included generous start-up funding from the Copper Country Intermediate School system to provide equipment for the high school students—both an Amatrol Skill Boss unit and additional Parker-Hannifin basic and advanced hydraulic training equipment.

In addition, the MMET department has invested in additional Amatrol pneumatic training equipment to supplement the current capabilities in power systems.

“The MMET department is clearly the leader on the Michigan Tech campus for fluid power.”