The following guest post was written by Kaylee Betzinger, a former student process improvement coordinator here at Michigan Tech and currently an intern at Amway in their Enterprise Excellence Department.

For the past 13 weeks I’ve been interning with Amway in their Enterprise Excellence Department. While in this position I’ve gotten to partner with a variety of cross functional teams throughout the business and within the West Michigan community. One project in particular is a non-profit venture with Mel Trotter Ministries. Mel Trotter Ministries exists to demonstrate the compassion of Jesus Christ toward the hungry, homeless and hurting of the greater Grand Rapids area (www.meltrotter.org/mission). They are able to provide a variety of services to these people in need because of their 4 thrift shops located throughout West Michigan. I’ve been working closely with Greg Alvesteffer, Assistance Vice President of Retail, on their donation process.

Before I began working with Greg and his team, their donation processes were quite a mess. First and foremost, there was no standard process spanning all of the stores (yikes!), making it difficult for the store managers and Greg to share ideas with one another. We also found numerous wastes in their process, the biggest being over processing. Multiple employees were touching the same donation multiple different times which was resulting in huge batches (they would create a batch of 50 donated clothing articles, then push them down an “assembly line” for the next employee to work on). While observing at the Gemba, we asked the question “Why do you create these batches?” That got me a variety of answers and a few weird looks, but ultimately the answer was “that’s just how it’s always been,” a typical answer in non-continuous improvement environments.

After multiple days observing and a few hundred questions we began to experiment and change things around a bit. My Amway mentor, Steve Sweers, and I explained the value of one-piece flow in what Steve calls the OHIO method (Only Handle It Once). This really seemed to resonate with Greg and the employees we were working with.

After a few weeks of experimentation, I did some time study evaluations to compare the old process with our new process and the results were astounding! By eliminating the batching process and installing a one-piece-flow production we were able to decrease space requirements by 70%, reduce labor requirements in that area by 83% (they were able to reallocate several employees to other departments within the store), and ultimately increased productivity by 480% (yes, that is possible!). It’s incredible to know that we were able to get these results without any capital investment. All we needed was to apply some continuous improvement principles in their processes and presto, huge improvements!

Being able to share this knowledge with a business like Mel Trotter has been such a rewarding experience. I will be continuing this partnership this fall where we plan to continue to make improvements throughout their retail stores.

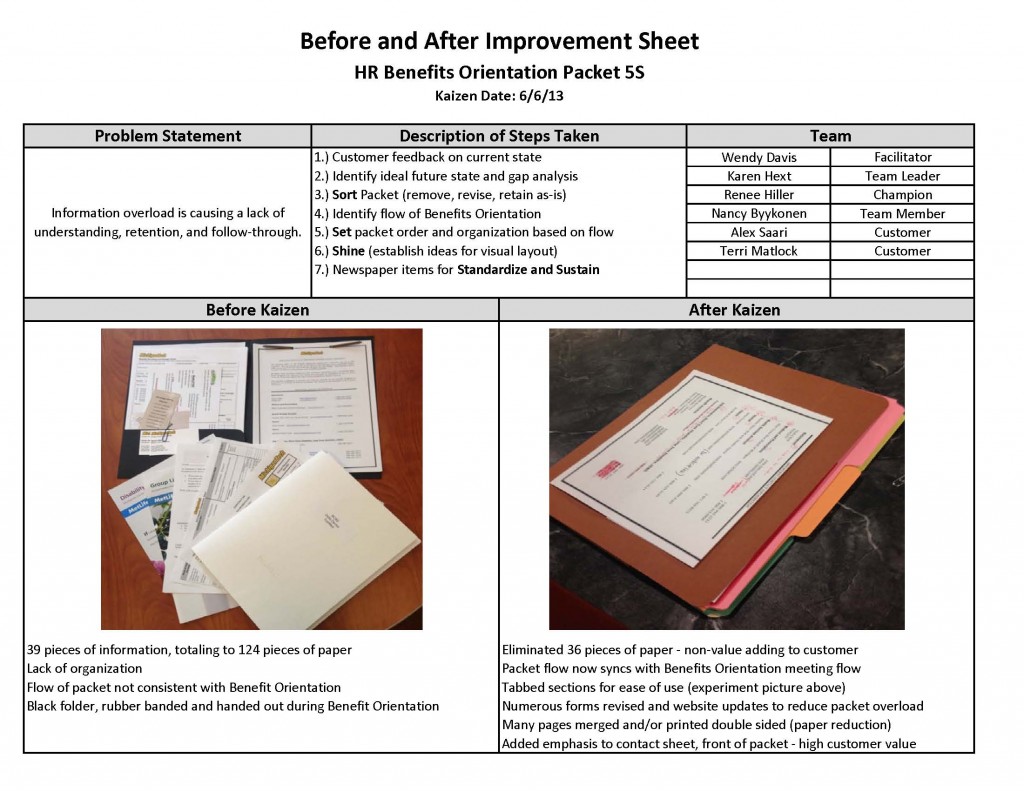

to ensure the gains made with the 5S activity are maintained.

to ensure the gains made with the 5S activity are maintained.