The Applied Chemical and Morphological Analysis Laboratory (ACMAL) is a shared facility located in the Minerals and Materials building on Michigan Tech’s campus. ACMAL has a wide range of electron microscope and x-ray analysis instruments available to the Michigan Tech community and guest researchers.

Over the past year, several ACMAL labs have been equipped with new software and cameras for improved remote teaching and research! These new remote capabilities allow for live/recorded demonstrations to be shared with large classes or for research clients and to view live data collection.

Below are descriptions of these instruments and laboratories affected:

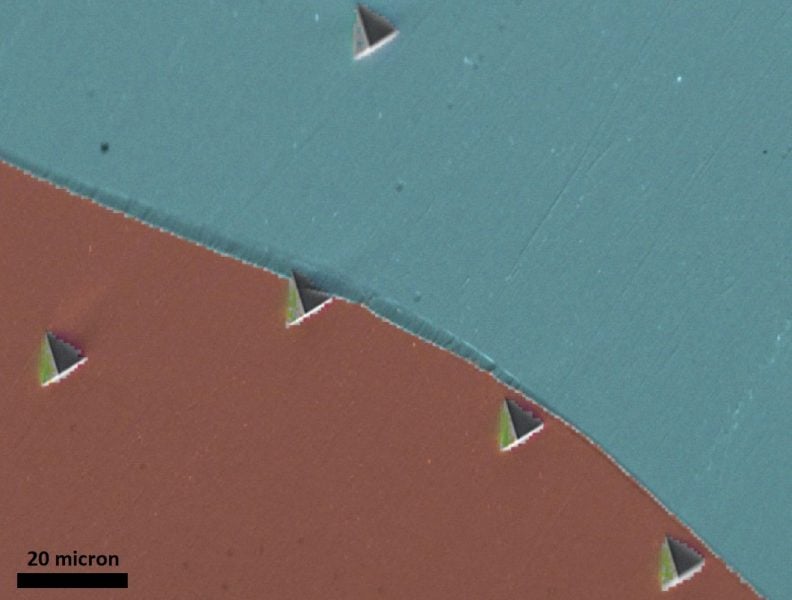

FEI 200kV Titan Themis Scanning Transmission Electron Microscope (STEM)

The STEM is Michigan Tech’s newest electron microscope addition that has atomic resolution imaging capabilities. The instrument has the following capabilities and modes: conventional TEM mode, scanning TEM mode, electron energy loss spectroscopy, energy filter TEM, high angle annular dark field, ChemiSTEM, Super-X Energy Dispersive X-Ray, and nanometer scale tomography.

New remote capabilities include:

- Zoom screen-share from both the TEM laboratory web camera and instrument control monitors

- Huskycast (Panopto) recording of lab space, TEM lab camera, and instrument control monitors

Learn more about the STEM: ACMAL – FEI 200kV Titan Themis STEM

Contact Elizabeth Miller (eafraki@mtu.edu) for more information.

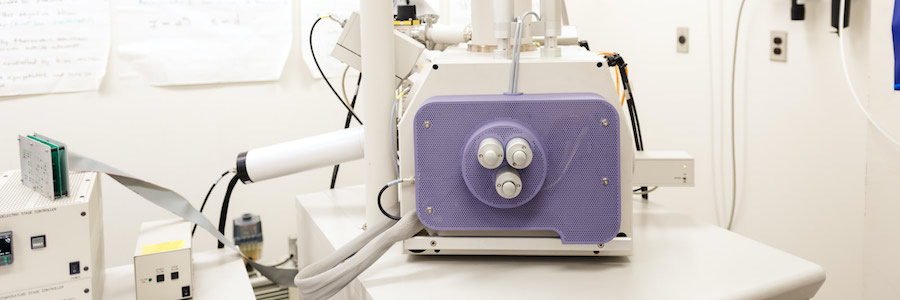

FEI Philips XL 40 Environmental Scanning Microscope (ESEM)

The ESEM can be used to image a wide range of material types at a microscale including hydrated, contaminated, organic, or inorganic samples. This microscope itself has several modes and features that make it a flexible instrument for any research needs: SE/BSE imaging, thin window EDAX EDS, electron backscatter diffraction, high and low vacuum modes, and hot or cold stage options.

New remote capabilities include:

- New laboratory web camera

- Zoom screen-share abilities from both the microscope control and AzTEC analysis computers

- Remote technical assistance with Raritan DKX4-101 KVM-over-IP

- Remote operation with Raritan DKX4-101 KVM-over-IP

Learn more about the ESEM: ACMAL – FEI Philips XL 40 ESEM

Contact Elizabeth Miller (eafraki@mtu.edu) for more information.

X-Ray Facilities: Scintag XDS2000 Powder Diffractometer and Scintag XDS-2000 PTS

ACMAL’s X-ray facilities (XRF) has instruments capable of performing x-ray diffraction (XRD) analyses on both powder and solid samples. Sample data such as present phases, lattice parameter, percent crystallinity, and texture analysis can all be found using MTU’s Scintag XDS2000 Powder Diffractometer and Scintag XDS-2000 PTS XRD instruments. These instruments have the following features to expand the types of samples that can be analyzed: zero background sample holder, custom powder sample holders, custom irregular shaped solid holder, custom liquid holder, ICDD-JCPDS database, and Anton-Paar high temperature stage.

New remote capabilities include:

- New cameras installed in both the instrument lab and sample preparation lab.

- Huskycast (Panopto) recording for both cameras and lab computer monitors.

- Zoom sharing available in both labs and computer monitors.

Learn more about X-ray facilities: ACMAL – X-Ray Facilities

Contact Dr. Edward Laitila (ealaitil@mtu.edu) for more information.