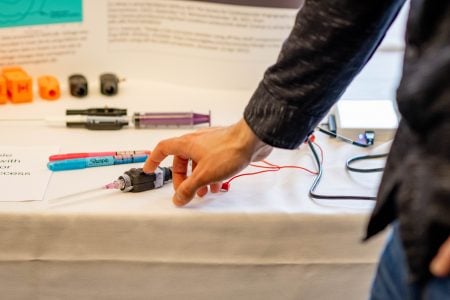

Interested in supporting Michigan Tech students as they engage in hands-on, discovery-based learning? Volunteer to serve as a judge at Design Expo 2023.

“We welcome judges from various professions, disciplines, and backgrounds to serve as judge,” says Briana Tucker, Enterprise Program associate director at Michigan Tech.

Now is the time to register to serve as a distinguished judge at Design Expo, coming up on Tuesday, April 18, 2023 from 10 am to 2 pm. This year the annual event will be held in person in two locations on campus at Michigan Tech: the J. Robert Van Pelt and John and Ruanne Opie Library, and the Memorial Union Ballroom.

Hosted by the Enterprise Program and the College of Engineering, Design Expo highlights hands-on, discovery-based learning at Michigan Tech. More than 1,000 students in Enterprise, Senior Design, and other Student Project teams will showcase their work and compete for awards.

In-person judging on the day of the event usually takes about an hour, depending on the number of volunteers.

Who should judge?

- Anyone with interest in supporting our students as they engage in hands-on, discovery-based learning

- Alumni

- Industry representatives

- Faculty and staff

- Community members

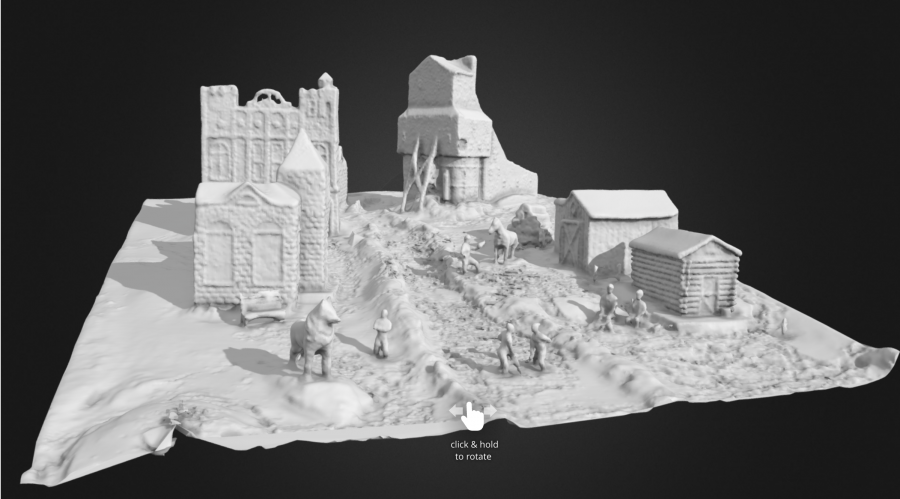

This year, prior to the event on April 18, judges will gain access to a digital gallery of student-created videos, in order to preview the videos prior to judging.

Design Expo 2023 is generously supported by industry and University sponsorship, including over 100 project and program supporters who make a strategic investment in our educational mission at Michigan Tech.

Sign up here to serve as a Distinguished Judge

at Design Expo on April 18, 2023.

Please visit Michigan Tech’s Design Expo Judges and Guests page for more information and to register to judge as soon as possible.

The Duties of a Design Expo Judge:

- Attend Design Expo for about an hour, sometime between 10 a.m. and 2 p.m. on April 18, 2023, to visit assigned teams.

- Review and score assigned team videos via RocketJudge, an online platform prior to the start of Design Expo.

- Each judge will be assigned 3-5 teams to score throughout the judging period.

“Whether a judge or simply a guest, your involvement in Design Expo is greatly valued by our student teams.”

Questions?

Feel free to contact Briana Tucker, Associate Director, Programming and Campus Engagement

The Enterprise Program at bctucker@mtu.edu