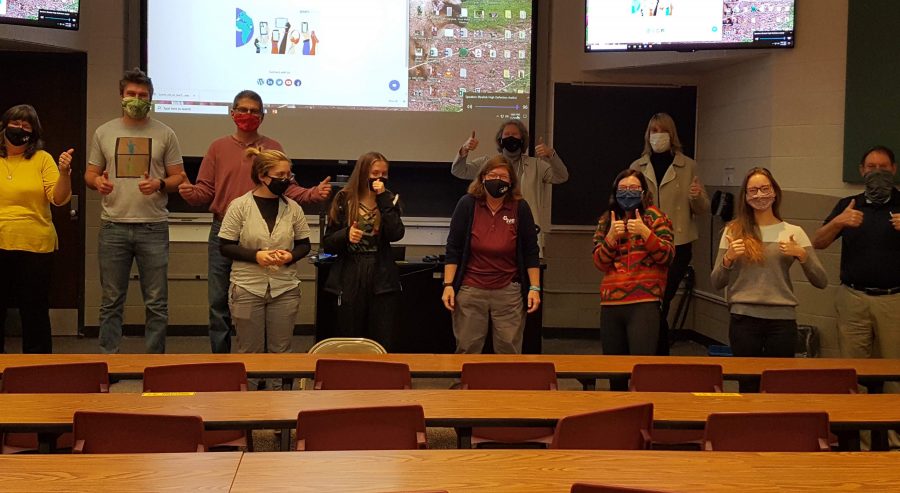

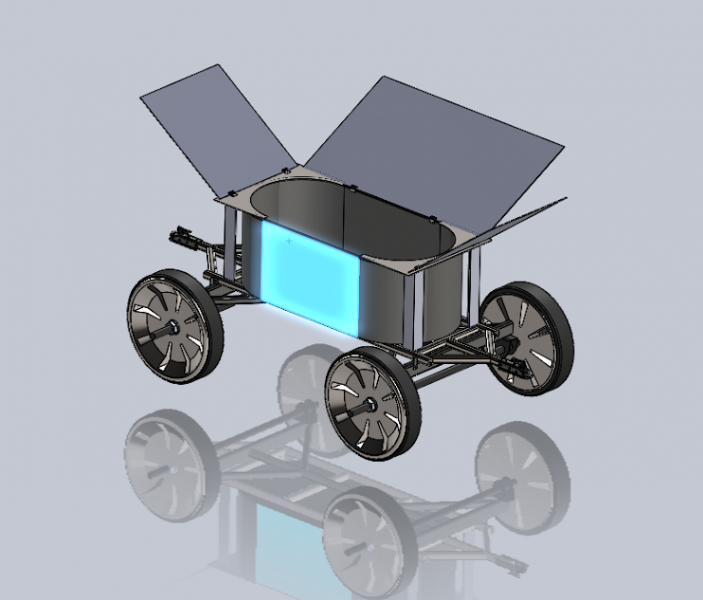

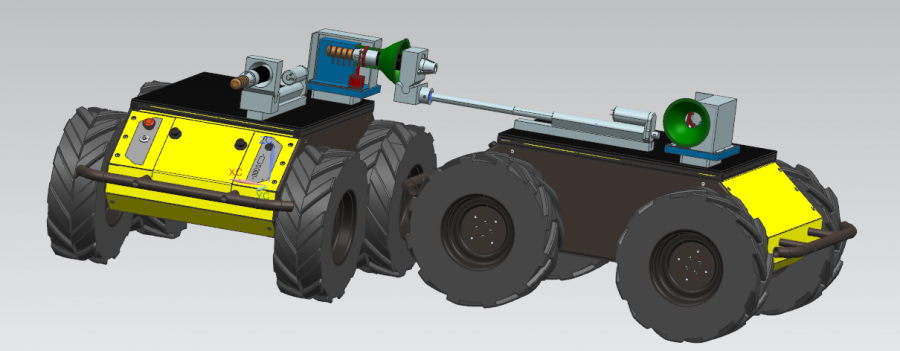

“We’re very excited about two sponsored projects that are underway this fall 2020,” says John Irwin, chair of the Department of Manufacturing and Mechanical Engineering Technology at Michigan Tech.

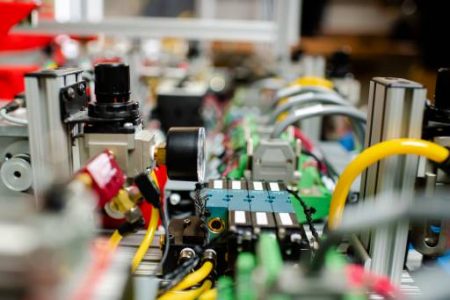

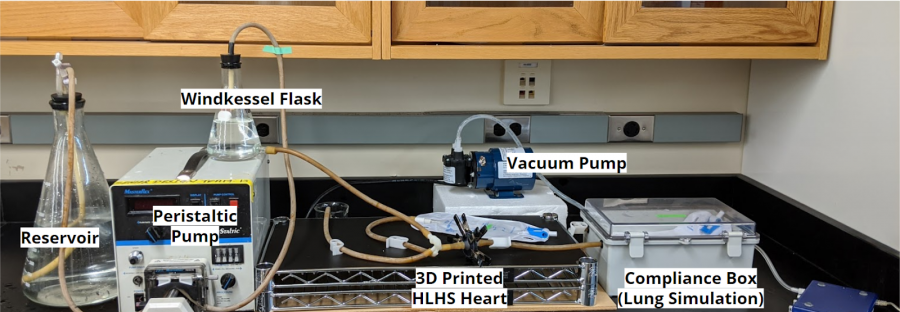

“Members of our MMET Industrial Advisory Board from three different companies supported projects, providing two student groups with a scope of work to research solutions, develop alternatives to design and then manufacture prototypes of those solutions. We are very thankful for the support of Kohler, Balluff and Pettibone for the sponsorship of the fall 2020 projects.”

Be sure to check out the student presentation videos for the Balluff/Pettibone project and the Kohler project.

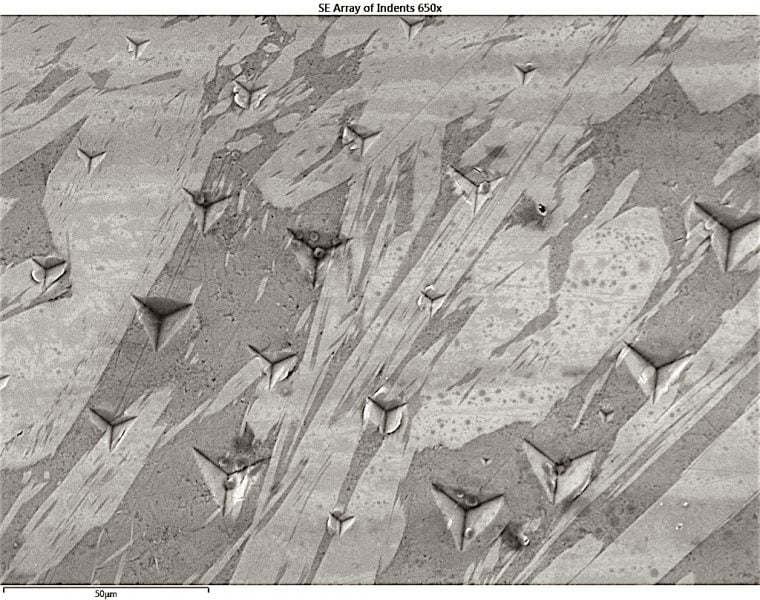

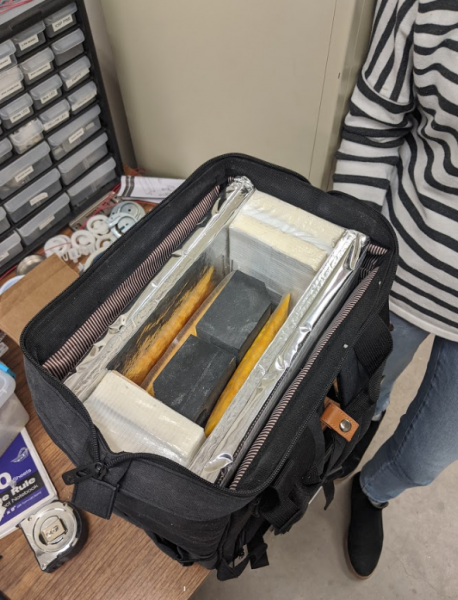

“The MMET Machine Shop remains extremely busy delivering courses that utilize the machine shop facility, generating parts and designs for research projects, machining and fabrication for enterprise projects, and of course the fabrication of MET senior capstone projects,” adds Irwin.

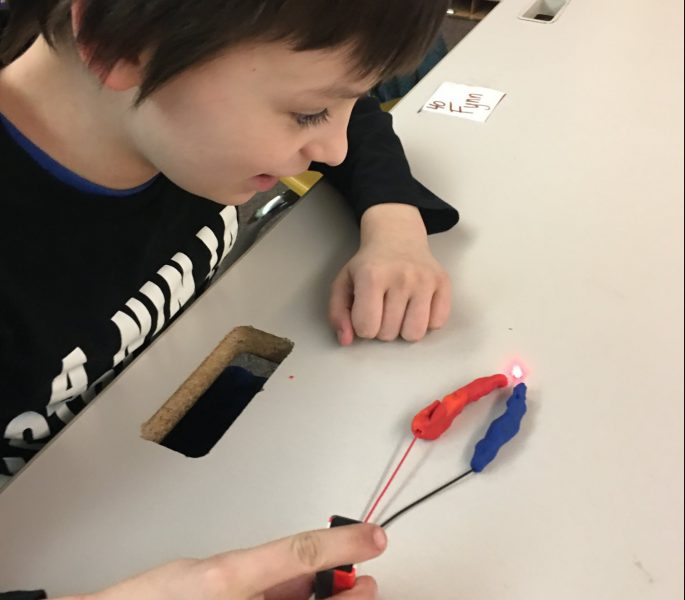

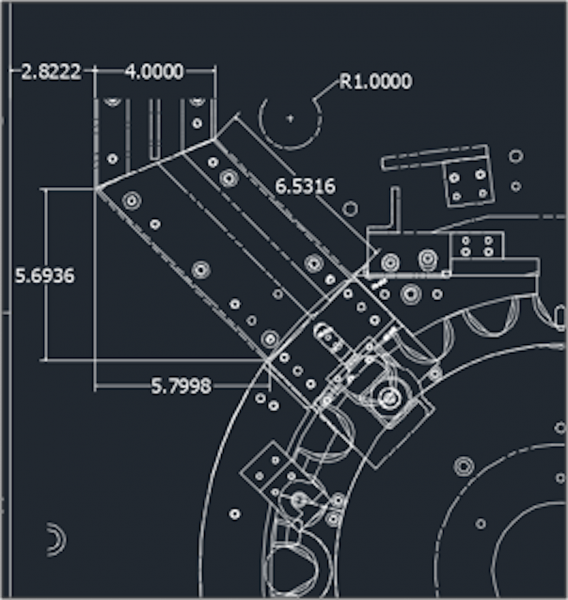

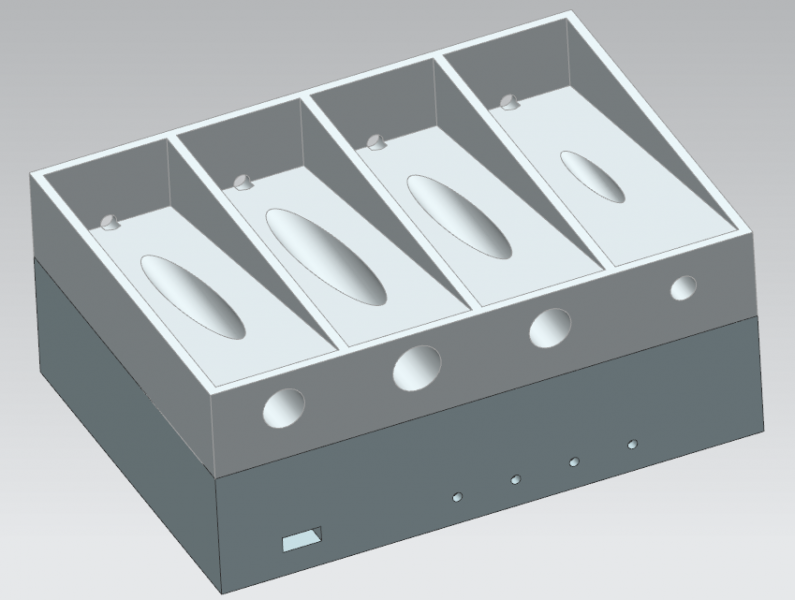

One of the recent additions to the machine shop are two CNC Tormach Lathes with an 8-station turret, and a full enclosure with coolant nozzle.

MET students are using the new equipment to develop a Tailstock redesign as a capstone senior project. The project started last spring. Check out their senior design video for full details

Read about previous MMET senior projects in greater detail here.