We are pleased to present this guest blog post by Mark Randell, Director of Rehabilitation and Sports Medicine at UPHS Portage.

Yes, we tried Lean.

I was fortunate to start my Lean journey and see success first hand with very little knowledge of Lean principles. We solved an inventory management problem at my work using visual management tools and Kanban cards. This small event saved us a ton of time and frustration. We no longer run out of patient supplies or overstock our supply closets. The pivotal event for me was participating in a week long kaizen at Pettibone. The thing that amazed me was the entire company was involved in the event and the organization made the changes suggested by the team the following Monday. I’ve sat in numerous meetings over the years talking about what we’re going to do and not really accomplishing anything. The Lean-thinking folks at Pettibone implemented improvements on Monday!

I started this blog post with my early success because it didn’t take long before I ran into a ton of fun wreckers. The comments I heard were:

- Lean has a life cycle.

- We tried Lean many years ago; it didn’t really work.

- This is another fad.

- It didn’t work at Toyota–look at their recent recalls.

If I would not have seen the early success of Lean/continuous improvement and met my coaches, Ruth Archer and Jim Manley, I would have focused my efforts back to return on investment and efficiency training. The question is, then, why does Lean/continuous improvement fail?

Jim Manley, a former executive at GM, believes they struggled at GM because they didn’t change the organizational culture to lean thinking. Art Byrne, in his book The Lean Turnaround, did not appear to be satisfied with the Lean implementation at IBM because IBM did not change the culture. Many of the MBA programs across the country were built on GM and IBM business principles and focused on return on investments and productivity. I believe the only way a company can successfully implement Lean is by changing the culture to Lean thinking. Lean is about changing the process by creating Lean thinkers, using Lean tools, and following Lean principles. If your goal is to decrease expenses by using Lean tools you will fail.

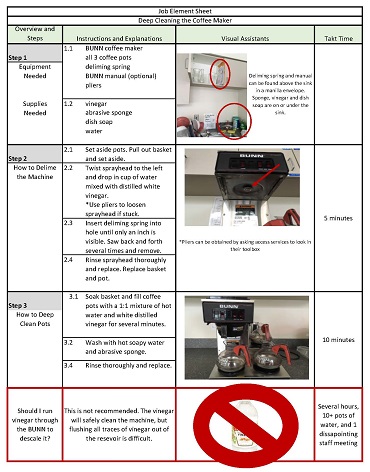

I formatted the job element sheet based on the one used by Catering Services for, coincidentally, making coffee. After picking out the steps involved and taking photos, I realized it would be easy enough to also create a sheet for how to brew a pot of coffee. Maybe it’s my love of the perfect cup of joe, the intimidating nature of a commercial coffee maker, or the fact that it can be difficult for many people to remember how much coffee to use, but for whatever reason I’m also the one who usually makes coffee for staff events. For being such a simple process, I know from experience that there are an outstanding number of ways it can go wrong! I tried my best to draw on this knowledge to help others avoid mistakes like pouring water into the machine without a pot underneath or forgetting to turn the burner off.

I formatted the job element sheet based on the one used by Catering Services for, coincidentally, making coffee. After picking out the steps involved and taking photos, I realized it would be easy enough to also create a sheet for how to brew a pot of coffee. Maybe it’s my love of the perfect cup of joe, the intimidating nature of a commercial coffee maker, or the fact that it can be difficult for many people to remember how much coffee to use, but for whatever reason I’m also the one who usually makes coffee for staff events. For being such a simple process, I know from experience that there are an outstanding number of ways it can go wrong! I tried my best to draw on this knowledge to help others avoid mistakes like pouring water into the machine without a pot underneath or forgetting to turn the burner off. The two Lean fundamentals are respect for people and humility. Respect for people is more than just using your manners. In the workplace, it’s about valuing individuals and their knowledge about how the process actually works, coaching others to develop their problem-solving skills, and solving problems by focusing on the process, not the people. Humility comes when you admit that you don’t know how to solve every problem. This drives you to seek out the ideas of all the people involved in doing the work. Together these fundamentals create a blame-free environment where continuous improvement is the norm.

The two Lean fundamentals are respect for people and humility. Respect for people is more than just using your manners. In the workplace, it’s about valuing individuals and their knowledge about how the process actually works, coaching others to develop their problem-solving skills, and solving problems by focusing on the process, not the people. Humility comes when you admit that you don’t know how to solve every problem. This drives you to seek out the ideas of all the people involved in doing the work. Together these fundamentals create a blame-free environment where continuous improvement is the norm.

Take a look at the list of our

Take a look at the list of our

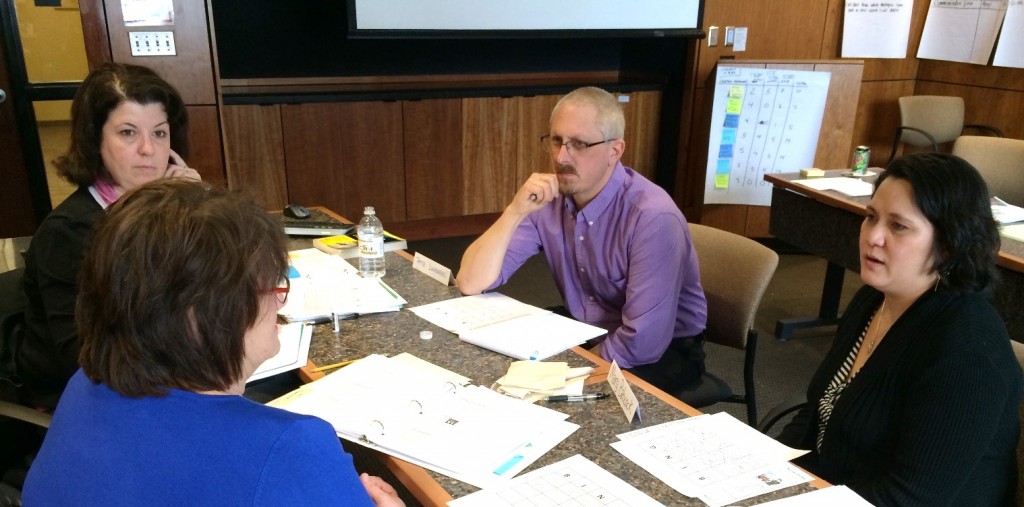

telling me other things that can be done with Lean on campus. It was a great experience for me and opened my eyes to other possibilities with Lean and left me wanting to know more.

telling me other things that can be done with Lean on campus. It was a great experience for me and opened my eyes to other possibilities with Lean and left me wanting to know more.