Every project should start in the work area where improvement is expected. As improvements are implemented, additional visits to the area are in order to ensure that employees in the area understand and benefit from the improvements. At the end of the project another visit is needed to ensure that the control plan is fully implemented and effective.

Bonus: Ineffective control plan

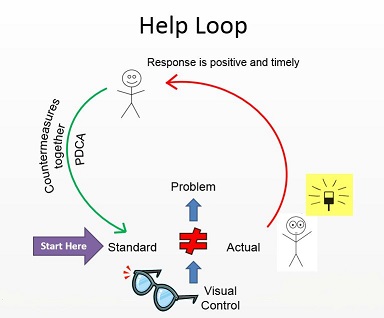

Unless something is put into place to prevent returning to “the way it has always been done,” the process will slide back to what it was. The tendency is to put in more instructions, signoffs, control charts, etc., in an attempt to control the process. But this is not the way to go. The new process must be easier to run than the old. It must make the operator’s job simpler, better, faster. It must make going back to the old way undesirable or hard to do and the new way pleasant and a joy. This requires careful thought and ingenuity from the team, and close involvement and feedback from the workers in the process. But please don’t jump to an engineering solution involving capital. There are other, cheaper, ways to accomplish this — you just have to dig them out.

Looking at these various pitfalls, it seems that they are often inter-related and linked. As a result, like a set of dominos, one problem leads to another, leads to another, often exponentially. If you need to improve your process improvement process, make it a project. Get a team of the right people together, charter the project, and use the tools to make improvements. Look at potential (or existing) problems as opportunities for improvement — and go after them.