The Auxiliary Services Customer Appreciation Week was held at Michigan Tech a few weeks back. One event that we’d like to highlight today was the tours in the MUB which featured Lean improvements.

Heidi Reid, the Facilities and Events Coordinator at the MUB shared a bit about the tours: “The Lean tours consisted of several “day to day” continuous improvements that take place in our office and building.” The tour started off with their 5S improvement project for their inventory of office supplies. The 5S improvements to the supply closet and ordering system have been sustained for over 4 years and counting.

Standardized work was also covered on the tour, “We used standardized work for many areas including managing our guest room reservation/check-in procedure. We utilize a practice of standardized work called knowledge folders, which are step by step instructions for many routine operations. If a student worker needs to perform a duty they are not familiar with, they can use these folders to complete the task” stated Reid.

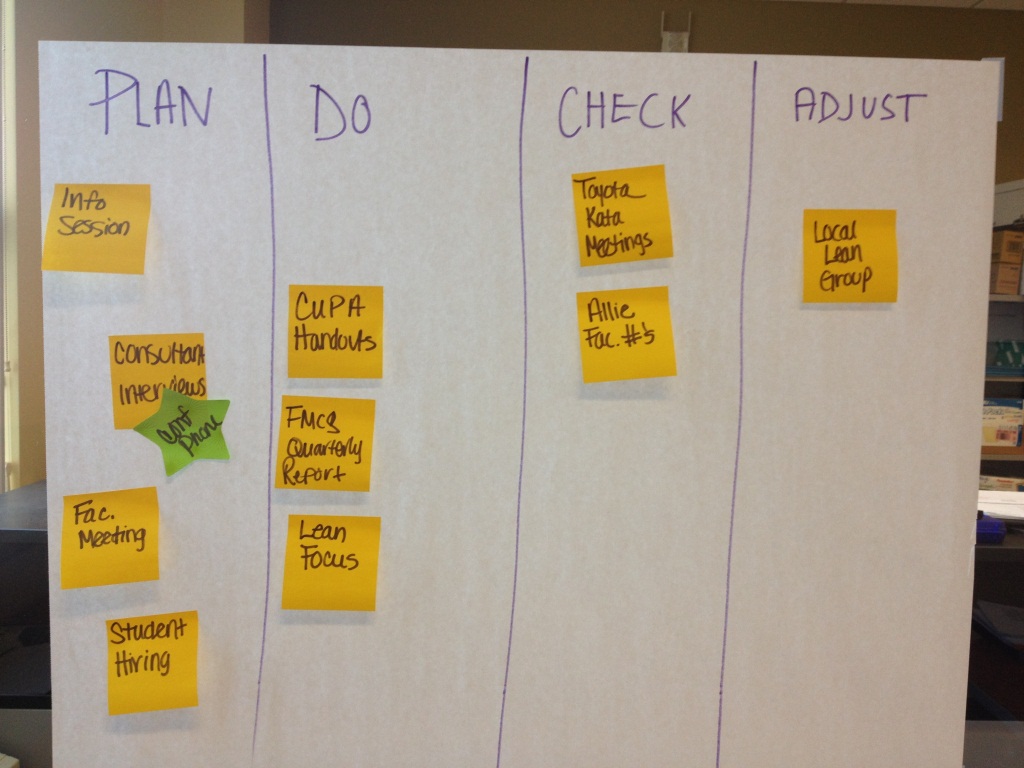

Other Lean improvements and tools covered on the tour were the value of auditing, daily team meetings , and visual controls. Reid added “our office staff are working every day to improve our processes and streamline daily work, in an effort to satisfy our customer’s needs.”

The tour sparked new interest in Lean practice to those who participated. Karen Patterson, new to the University and the Center of Diversity and Inclusion, had a positive experience on the tour. Karen came from Portage Health, where many of the nurses are practicing Lean. When asked about her overall impression of the tour Karen said she was very excited to hear about all of the improvements. Karen has taken the next steps to bring Lean to her new role and will be presenting some ideas to her office at their May department meeting.