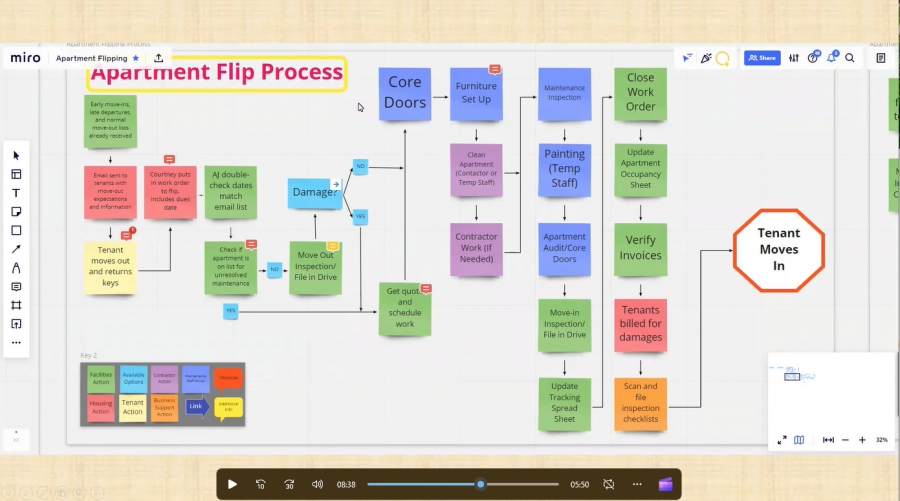

AJ Mikus is the Facilities Manager for the Daniell Heights apartment complex at Michigan Technological University. AJ led an improvement event designed to improve the student experience of checking out of their apartments, reduce the amount of repairs needed, and ensure all damages were properly accounted for. Watch AJ’s report out on his kaizen experience at our Lean at Michigan Tech YouTube channel.

It has been a great journey over the past two years as a process improvement coordinator (PIC) and as graduation is just two weeks away this will be my last post. I have really enjoyed working with so many different people and being a part of real changes across campus.

Since starting in July 2014, I have helped out by being a Lean facilitator for 3 on-campus events and a PIC for 14 campus improvement events across 5 departments at Michigan Tech. These events have helped campus save over 400 hours of time for Michigan Tech’s staff, and over $4,000.00 in waste, along with alleviating countless amounts of stress all around. The projects have ranged from helping employees 5S their workstation, to aiding the Van Pelt and Opie Library staff in standardizing the archive binder process, to helping student organizations like the MTU FilmBoard come up with standardized processes for their equipment set up. I have also been able to assist in 5 office projects ranging from informational wall posters which can now be seen outside our office, to marketing videos that including a cameo appearance by Michigan Tech’s President Glenn Mroz!

I first learned about Lean from my co-op with Kimberly-Clark in one of their manufacturing mills located in Ogden, Utah, and I have been able to take it with me as far as Boston when I met up with John O’Donnell for the second time at the Lean Enterprise Institute headquartered in Cambridge, Massachusetts. A selfie of that visit can be seen below (I have blogged about it before). I love Lean because it not only promotes order and information transparency, but also underlines having respect for people.

I would like to thank the entire Office of Continuous Improvement for the time and patience they poured into me upon my arrival, as I was becoming more fluent in my understanding of a what a Lean culture really is. After graduation I will be trading Houghton, Michigan for Seattle, Washington, all the while spreading the Lean spirit that I have learned to love over these past two years. Best of luck to the newly hired PICs–I have full trust that you’ll continue down the great pathway this office is on and fall in love with Lean as much as I have.

The Leaders in Continuous Improvement (LCI) student organization had the opportunity to visit Pettibone, LLC on Tuesday, October 13th. Pettibone, located in Baraga,MI, manufactures various “big” machines that aid in the construction of railroads, residential homes, and forestry projects.

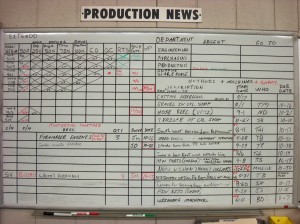

Throughout that past 10 years, Pettibone has implemented lean principles in many different areas of their business. It is extremely prevalent throughout their shop floor. The moment we walked through the doors we could see visual cues and signals; from the floor under our feet to the red “Fire” flags hanging all over the walls. The floor is marked with three different colors: yellow, green, and blue. Blue indicates a meeting space (where they have their daily huddles), Green is a walkway for employees and visitors, and Yellow representswhere the work is being done (or where the machines are being built). You can easily see the different colors in the photo below. Pettibone has a great space dedicated for their daily huddles where they discuss all of the production related items. The boards are easily readable to anyone and are colored coded (red=bad, green=good) so at a glance anyone can see how things are going.

These are just a few examples of how Pettibone utilizes lean principles in their every day work.

Overall the trip was a great experience for all the members of Leaders in Continuous Improvement. I would recommend a trip to Pettibone to anyone who is interested in learning more about Lean and Continuous Improvement.

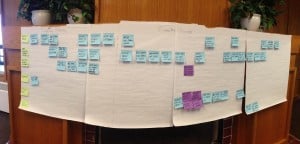

Last week, The Rozsa Center for the Performing Arts held a kaizen event to improve their rental processes. The current process is inconsistent and very confusing for all parties involved including the client, rental staff, administration, production staff, Ticketing Services, and Catering. In order to see what the current state of the process is, the team decided to map out the process by way of a swim lanes process map. Before the team began creating the process map, Bob Hiltunen-Director of Auxiliary Services, provided some great process mapping guidelines that really helped the team. They are:

- There is no right or wrong way to map

- You don’t learn how to process map, you process map to learn

- Process map what is, not what you would like it to be

With these guidelines in mind the team was able to create a process map that included each department/area that the process touches and all of the process steps from start to finish (see image below).

With the initial map created the team was then able to move forward in creating an “ideal state” process map. The ideal state captures the process in a perfect world with all the necessary resources available. The team was able to look back at the current state map to compare steps and people involved with the ideal state map. The team will continue to work on their ideal state in the next few weeks and then form a plan to move from current to the ideal. Check back to see the final results in a future post.

Leaders in Continuous Improvement (LCI) recently had the opportunity to go on an industry tour to Parker Hannifin’s Manitowoc Wisconsin facility. With the help of a Michigan Tech Alum who is now a Value Stream Team Leader at this plant, the students in LCI were able to see first hand what a Certified Lean Model Plant (Parker’s Manitowoc facility became Lean Certified in April 2013) looks and feels like.

From the moment you walk through the doors you can see how truly “Lean” this plant is. From the visual signs and lights, to the tape outlines all across the plant floors, to their daily huddle area they call their “board walk,” Lean is definitely a theme at this plant.

The tour began with everyone becoming equipped with the proper safety equipment. Each individual was given a bright orange safety vest, protective eye goggles, and a head set with a walkie-talkie so we could hear our guide properly once on the plant floor. It was exciting to see how valuable a safe working environment was for the Parker Hannifin team.

Once everyone was suited up, we were able to attend their daily board walk. Within the huddle space there are nine different white boards that represent a different team or topic. There is a representative for each board that gives an update to the team. What I found so great about this style of daily huddle is that they did some actual problem solving on the spot. One team was having an issue so they started asking questions and brainstorming different improvements. In addition to the white boards themselves, Parker utilizes visual cues in the form of plastic solo cups. On top of the boards are stacks of red and green solo cups. If there is a problem or issue the team will place a red cup on a peg, indicating a problem. If the team has no issues they will place a green cup on the peg. This was just the beginning of the visual cues throughout the facility.

Once we began walking through the facility we really began to see just how deeply rooted Lean is in the Parker Hannifin culture. Each team at Parker Hannifin uses a team communication board. This board contains the different metrics the team tracks, daily audit sheets, a 5S checklist, the different job description sheets needed for all the different tasks, and a space for various communications. In addition to the communication boards, many teams use a kanban board that allows the team members to see exactly what materials/tools they will need for the current job and the job “on deck.”

All in all, the industry trip was beyond what we expected. It was a great opportunity for the students to learn more about continuous improvement tools and concepts and see what a lean culture truly is. A special thanks to Megan Mattila, who helped to coordinate everything and was our fantastic tour guide.

One of the initiatives that the office of continuous improvement has for fiscal year 2015 is to incorporate more Kaizen events into student organizations. As president of Michigan Tech’s American Society of Mechanical Engineers (ASME) student chapter I was having frustration regarding the current state of our process of supporting the annual Student Design Competition (SDC). In this process a group of students builds a robot to go through an obstacle course. Trouble lied in communication and failure to compete in the competition even after thousands of dollars was vested in the activity. It then struck me that I could integrate my two activities, my work at the Office of Continuous Improvement and also ASME to be mutually beneficial.

To help launch the Lean mindset in the student organization I invited Ruth Archer, Manager of Process Improvement, to introduce at a very basic level some tool they could integrate into their daily life. This helped show the members common industry practices of Lean, and continuous improvement. Ruth also spoke to them about how Michigan Tech works to make sure that there are continuous improvement efforts being done on current processes through the office of continuous improvement. This gave the students new insights into how the university was working at improving their experience as students of Michigan Tech.

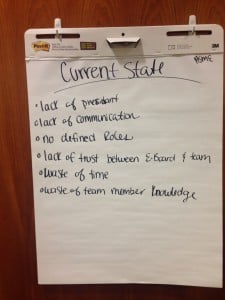

A few days after this presentation the pre- meeting for the ASME SDC team Kaizen event. I was put on as the team leader with Laura Henry and Jim DeRochers acting as co- facilitators and Kaylee Betzinger acting as the student process improvement coordinator. The current state was outlined and can be seen in the image below. Items included the lack of definite rolls and lack of time.

A week later the actual Kaizen event was held with the team members of the design team, the executive treasurer of ASME, as well as all support persons facilitating the Kaizen present.

Some images of the current state were taken from the Kaizen event and can be seen below.

The competition took place on April 10th and I look forward to seeing how integrating Lean practices helps the team in years to come as the most use from this event will come in this years preparation for the competition. One of the major outcomes is that Kaizen communication has been streamlined between the team and the executive board and an increased amount of documentation though Google Drive.

If your student organization is having trouble with a current process contact the Office of Continuous Improvement at: 906-487-3180, e-mail improvement@mtu.edu or request a Process Improvement Event here.

A recent partnership has been formed between the student organization Leaders in Continuous Improvement (LCI) and local non-profit 31 Backpacks. 31 Backpacks is a non-profit organization that sends food home in backpacks every Friday and school breaks for eligible children. The teachers, principals, and counselors at each school identify the children who need assistance and aid in the giving of the food bags.

Laurel and Melissa Maki, the founders of 31 Backpacks, were very enthusiastic about partnering with Leaders in Continuous Improvement (LCI) and a game plan was formed right away. It was decided that LCI would begin with a storeroom 5S.

5S is a workplace organization methodology used to eliminate waste, organize a workplace, and create a system to sustain improvements. The 5 S’s stand for Sort, Set in order, Shine, Standardize, and Sustain. The members of LCI were able to completely re-vamp the existing storeroom (as you can see in the pictures). In order to properly sustain this improvement, a weekly audit was created. This will allow various volunteers to “audit” the

storeroom to ensure sustainment of the improvements.

Although we haven’t fully implemented the new process, this is still a huge improvement from where we were at the beginning. This is a great starting place for a hopefully long partnership.

Be on the lookout for future improvements from the LCI and 31 Backpacks partnership!

During a recent Auxiliary Services Report Out, Bob Hiltunen gave an incredible teachback demonstrating the benefits of one-piece flow over traditional batch and queue. He was able to do this through an exercise we call “The Quarter Pounder.” One-piece flow refers to the concept of moving one work piece at a time between operations. This may also be referred to as the OHIO method (only handle it once).

To learn more about The Quarter Pounder activity, read a previous blog post by fellow Process Improvement Coordinator Nate Hood by clicking here.

The group of participants really enjoyed this fun, hands on exercise. It was great to see the mental light-bulbs going off when each participant saw the difference between batching and one-piece flow.

No matter who is participating in this activity, the results are always the same. By eliminating the batching and implementing one-piece flow, the team is always able to decrease the total process time, and the time it takes for the customer to get their first item plummets. During this round of the exercise, the team was able to decrease total processing time by 289%!! How can implementing one-piece-flow in your organization benefit you?

Often times you can’t help but overhear conversations between your fellow classmates, and regularly the topics of interest revolve around two things–how tough our winters are, and how bad our dining halls are. This unfortunate perception held by some students has sparked a flurry of improvement events currently being held on campus. The one I would like to highlight is the Residential Dining Blueprint kaizen that was conducted this week.

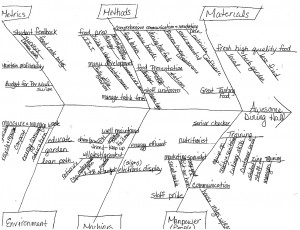

The cries have been heard and the dining hall managers spent 12 long hours over the course of three days creating a blueprint for “what makes an awesome dining hall.” As a student playing the “customer” role on the kaizen team it was very refreshing to see just how much each and every manager is devoted to improving the residential dining experience. In creating the blueprint the team took advantage of a great organizational tool: the Fishbone diagram (click on the diagram to enlarge it).

The dining hall managers and staff definitely have their work cut out for them, but that isn’t going to stop them in their pursuit of creating the greatest possible dining experience. I look forward to seeing the improvements in the coming years.

The Office of Continuous Improvement has begun a Lean Workshop series on campus. Thus far in the series we’ve held a 5S workshop, and another one is ready for you to sign up. The Office and the Lean Facilitators are working hard to plan regularly scheduled workshops throughout the year.

The next event in the series will be on Process Mapping. Process Mapping is a way to define the purpose of a process, who is responsible for each step, to what standard a business process should be completed, and how success can be determined. The workshop will take about 6 hours total on June 10th and June 12th. You can choose blocks of time that are convenient for you. For more information you can visit the Process Mapping Workshop page. Sign-up closes on Friday, May 23rd., because the facilitators need time to plan.