The Michigan Tech Formula SAE Car Team finished 23rd out of 110 teams at the 2015 Society of Automotive Engineers International Competition at the Michigan International Speedway in Brooklyn, Michigan. The Team took 25th in Acceleration, 26th in Endurance, 31st in Design and 31st in Business Presentation. They also won the 2015 MacLean-Fogg Fastening Challenge earning them a trophy and $1000. Way to go!!

The Michigan Tech Formula SAE Car Team finished 23rd out of 110 teams at the 2015 Society of Automotive Engineers International Competition at the Michigan International Speedway in Brooklyn, Michigan. The Team took 25th in Acceleration, 26th in Endurance, 31st in Design and 31st in Business Presentation. They also won the 2015 MacLean-Fogg Fastening Challenge earning them a trophy and $1000. Way to go!!

From Tech Today May 12, 2015

Dozens if not hundreds of area homes can be made cozier, thanks to a gift from Dow Corning.

The Midland-based company has donated 1,200 tubes of clear silicone sealant to the Efficiency Through Engineering and Construction Enterprise (ETEC) at Michigan Tech. The gift will be used to weatherize area homes as part of the Houghton Energy Efficiency Team (HEET) effort.

“We did it because we’ve always had strong ties to Michigan Tech, and because it’s an excellent program,” says Bob Schroeder, global procurement director for Dow Corning.

ETEC advisor Lynn Artman, a lecturer in Michigan Tech’s School of Technology and a HEET member, says the gift would be put to good use sealing leaks that let cold air into houses. “We focus on weatherizing homes for low-income residents,” she says. “That not only makes their homes more comfortable, it slashes their utility bills. I’m so grateful to Dow Corning for their support.”

HEET is a local volunteer group dedicated to helping Houghton County residents reduce their utility bills and to compete for the $5 million Georgetown University Energy Prize.

The Georgetown University Energy Prize challenges communities to rethink their energy use and implement creative strategies to increase energy efficiency.

Award Winners of the 2015 Design Expo at Michigan Tech have been announced and are listed below. A summary of links to photos, videos and news articles is also included.

Award Winners of the 2015 Design Expo at Michigan Tech have been announced and are listed below. A summary of links to photos, videos and news articles is also included.

The Design Expo highlights hands-on, discovery-based learning at Michigan Tech. More than 600 students in Enterprise and Senior Design teams showcase their work and compete for awards. A panel of judges, made up of corporate representatives and Michigan Tech staff and faculty members, critique the projects.

Many of them are sponsored by industry, which allows students to gain valuable experience through competition at the Expo, as well as direct exposure to real industrial problems. The fourteenth annual Expo is a combined effort of the College of Engineering and the Pavlis Honors College. The 2015 Expo was held in the Ballroom of the Memorial Union Building.

Meritor: Running Strong. Building Momentum. Looking Forward. Enterprise Awards

Based on poster and presentation

Enterprise –

1st Place Award – 215- IBV

Team Leaders: Leslie LaLonde and Andrew Clark, Biomedical Engineering

Advisors: Robert Warrington, Pavlis Honors College

Sponsor: Pavlis Honors College

Project Overview: The Infant Heart Annunciator is a small, BandAid-shaped device that detects an infant’s electrocardiogram, producing a visible flash and audible tone. Often in developing countries, those present at birth do not have the training or equipment needed to determine if an unresponsive infant is alive. Our goal is to eliminate this unnecessary loss of life. Our team is also designing a simple, yet reliable, ventilator that can be stockpiled by hospitals. Typically, hospitals maintain sufficient numbers of ventilators; however, an increase of patients resulting from a pandemic could create a shortage of ventilators. The current high cost of most ICU ventilators prevents hospitals from stockpiling these machines.

2nd Place Award – 212 – CPM

Team Leader: Paul Hagadone, Chemical Engineering

Advisors: Tony Rogers and Sean Clancey, Chemical Engineering

Sponsors: AFI, BASF Corporation, City of Midland, nanoMAG, Razor Edge Systems, Wisconsin and Southern

Railroad

Project Overview: CPM aims to exceed the expectations of company sponsors, improve the lives of consumers through innovation, and develop students into highly marketable professionals. The project goals for our

team include improving runoff models to provide advanced flood warning in Midland, designing a kiln

for cleaner charcoal production in Benin, using food waste as an alternative energy source at Michigan

Tech, developing a water filtration system to cool industrial process streams, curing coatings at lower

temperatures using catalysts, integrating hightech materials into athletic equipment, designing

collapsible packaging for a large volume of liquid product, and conceiving and testing an innovative

product idea from within CPM.

3rd Place Award – 224 – Velovations

Team Leaders: Ian Connick, Mechanical Engineering and Kyle McGurk, Electrical Engineering

Advisor: Steve Lehmann and Paulus Van Susante, Mechanical Engineering-Engineering Mechanics

Sponsors: Specialized, Thomson, Department of Kinesiology and Integrative Physiology

Project Overview: Our team is dedicated to working on bicycle and bicycling industry related projects. For the 2014-2015 academic year, Velovations has more than twenty-five students from various majors divided

into four projects. The projects are: a pedal that offers the ability to transition from clipped in to

a platform and back at the push of a button; a system to allow tire pressure change on the fly;

an inexpensive winter commuting tire; and an innovative exercise system for wheelchair users that will allow further physical research. Velovations projects cover the complete product development

range, from idea conception, research, and development, to customer communication, testing, and ultimately manufacturing.

Black and Veatch: Building a World of Difference® Senior Design Awards: Based on poster

Senior Design –

1st Place Award – 145 – Aluminum Corrosion Study

Team Members: Annie LeSage, Jacob Gerdt, Kyle Myszka, and Alexandra Glover, Materials Science and Engineering

Advisor: Steve Kampe, Materials Science and Engineering

Sponsor: Yazaki North America

Project Overview: The switch from copper to aluminum in automotive electrical systems is advantageous to U.S automakers and automotive component suppliers because it has the potential to decrease vehicle weight and raw materials costs. This switch also poses several challenges. This senior design project characterizes the galvanic corrosion rate of an aluminum substrate with a metallic plating when exposed to an electrolytic solution. This mimics the exposure of electrical components to a fluid containing salts or automotive chemicals. The results of this testing are critical to the success of the copper-to-aluminum substitution in automotive electrical systems. This is because they inform automotive component designers about the expected lifetime of such systems when exposed to a corrosive environment.

2nd Place Award – 130 – Front End Protection for Data Aquisition

Team Members: Sylvia Ferragut, Caleb Wright, and Ben Veltman, Electrical Engineering; Matthew Zawisza, Computer Engineering

Advisor: Duane Bucheger, Electrical and Computer Engineering

Sponsor: Department of Electrical and Computer Engineering

Project Overview: Often devices under test can behave in erratic ways, resulting in catastrophic damage to expensive test equipment. By designing specifications based on National Instruments’ limitations and typical automotive testing requirements, the team created a buffer box to protect from over-voltage and add layers of isolation. The buffer box, used in conjunction with the $50k–$500k tools being regularly used by the automotive industry, is a simple tool, which can be used by a wide range of people with varying levels of expertise to keep expenses down.

3rd Place Award – 110 – Design and Development of an Automated Stacker for Highway Products of Nucor Steel Corporation

Team Members: Logan Edwards, Sean Hayes, Stephen Penny, Electrical Engineering Technology; and Shashank

Lakshmikanth, Mechanical Engineering

Advisor: Seyyedmohsen Azizi, School of Technology

Sponsor: Nucor Steel Corporation

Project Overview: In this project, a robotic stacker is designed to enable precise stacking of highway sign posts produced by Nucor Steel Corporation, while complying with the required stacking pattern as

well as time constraints. Currently this process relies heavily on a manual work force, introducing

many safety hazards as well as inefficiencies and inconsistencies. This project offers a robotic

stacker solution using Fanuc robot manipulators, custom-built end-effectors, and a programmable

logic controller (PLC) integrated with human machine interface (HMI). This will result in smaller

and organized stacks as compared to the current disorganized bundles and removal of a worker from

the hazardous position in the process. Organized stacks will also allow for further downstream

automation processes.

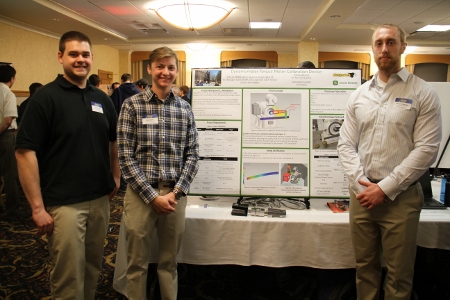

Honorable Mention 1 – 104 – Dynamometer Calibration Device

Team Members: Kristopher Benaglio, Christopher DeGroot, Adam Deibler, Kenneth Smith, Mechanical Engineering

Advisor: Paul van Susante, Mechanical Engineering-Engineering Mechanics

Sponsor: John Deere

Project Overview: This design team is working with John Deere to develop a new dynamometer torque meter calibration device. A dynamometer, commonly referred to as a dyno, is a popular test instrument used to measure variables such as torque, speed, and power output. The current calibration method used by John Deere utilizes a static weight stack attached to a moment arm. This design must be replaced because it exceeds the dynamometer test cell envelope, is difficult to transport from test cell to test cell, requires considerable time and effort for two workers to assemble and disassemble, and requires the repetitive lifting of 40 to 45 pound weights.

Honorable Mention 2 – 128 – Compliance Keweenaw..

Honorable Mention 2 – 128 – Compliance Keweenaw: Aspirus Keweenaw Hand-washing Compliance System

Team Members: Anna Waller, Jannah Brandt, Drew Markel, Creighton Bradley, and Rebecca Manshaem, Biomedical Engineering

Advisor: Bruce Lee, Biomedical Engineering

Sponsor: Aspirus Keweenaw

Project Overview: Hand hygiene is of importance to hospitals not only for the safety and health of employees but also to reduce the spread of hospital-acquired infections and protect patients. Aspirus Keweenaw recruited our team to create an automated system to track hand-washing compliance among employees to assist them in their goal of 100 percent compliance. We created a system using a microcontroller and

RFID readers to detect when a healthcare worker enters a patient’s room and reaches compliance

using the sanitizing foam dispenser. This system will be placed near the doorway and communicate with

a wristband that identifies the healthcare worker and vibrates as a reminder if compliance is not

reached.

Honorable Mention 3 – 138 – Chrysler 300 Split Tailgate

Honorable Mention 3 – 138 – Chrysler 300 Split Tailgate

Team Members: Kelly Shanahan, Joshua Yagley, Alex Bancroft, Jerad Marble, and Parry Ragland, Mechanical

Engineering

Advisor: Kevin Johnson, Mechanical Engineering-Engineering Mechanics

Sponsor: Fiat Chrysler Automobiles

Project Overview: Our goal is to design, engineer, build, and test a split decklid adapted from the current Chrysler 300 architecture. This decklid system will provide the customer both the access required of typical decklids without the upswing of the lower waterfall area and the added feature of a tailgate style lower swing out panel which will provide a surface for tailgate functions. This feature is rare in the industry and provides an opportunity for segment differentiation creating a unique selling point.

Summary: More information:

2015 Design Expo Photo Gallery

Video Playlist from Michigan Tech Expo Channel on YouTube

2015 Design Expo Image Contest Entries

The Design Expo 2015 Image Contest winners have been selected. Congratulations to MSE senior design team members Jordan Pontoni, Calvin Nitz, Shane Anderson and Austin DePottey for their first place image of a team member at work in the foundry. The image illustrates the team’s project, Casting 357 Aluminum, sponsored by Eck Industries. The team’s advisor is MSE engineer/scientist Thomas Wood.

Team 150, Title: “E357 Alloying to Increase Elongation and Maintain Mechanical Properties”, the foundry shot.

Robotics Systems Enterprise team won second place for its image of ECE student Kealy Smith working on an Afraid-of-the-Dark bot. The team is sponsored by ArcelorMittal.

then 216 (Robotics Systems Enterprise), and 205 (Blue Marble Enterprise).

2015 Design Expo Booklet (4Mb PDF)

2015 Design Expo Weblog (4Mb PDF)

Michigan Tech news article: Design Expo 2015 Success: Winners, Senior Design and Enterprise Projects

Pre-event news Michigan Tech article: Get Ready, Get Set: Design Expo 2015