In celebration of its 25 years at Michigan Technological University, the Enterprise Program has awarded eight inaugural Enterprise Distinguished Service Awards to recognize the dedication and exceptional contributions of advisors and champions who have played pivotal roles in shaping the program’s success. The recipients of the Enterprise Distinguished Service Award are Brett Hamlin, Glen Archer, Rick Berkey, Jason Blough, Brad King, Robert Pastel, Tony Rogers, and Christopher “Kit” Cischke.

Each of the award winners has more than 15 years of service within Enterprise, dedicating their time and expertise to guide teams, ensure student success, and advance the program’s discovery-based learning mission. The eight advisors have also fostered industry collaborations and strengthened the bridge between academia and industry.

This eight-part series highlights the contributions of each award recipient.

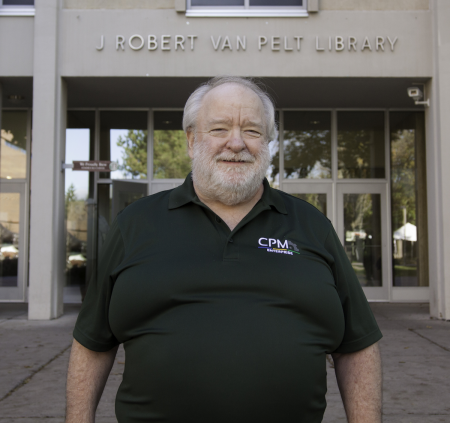

Christopher “Kit” Cischke, a teaching professor in the Department of Electrical and Computer Engineering, first came to Michigan Tech as a student in 1997. During his studies, Cischke helped found one of the original Enterprise teams, the Wireless Communications Enterprise (WCE). After graduating in 2001 with a bachelor’s in electrical engineering, Cischke spent several years in industry before completing his master’s in computer engineering at the University of Minnesota–Twin Cities. He then returned to Houghton to teach computer engineering classes and serve as advisor to the (now much bigger) WCE he helped found as an undergraduate.

After nearly 20 years of working with WCE, Cischke says his favorite part of working with Enterprise students is watching them take ownership of their projects.

“When students do projects in class, they work hard out of obligation,” Cischke says, “Their grade depends on it. But with Enterprise, students take real ownership. They want to succeed, and they put in the time to make it happen and they do cool things on their own volition.”

Cischke notes there have been many standout memories over his years as WCE advisor. One particular example that comes to mind is receiving a set of projects students worked on for Ford from roughly 2016 to 2018.

“A WCE student who interned at Ford talked to his boss and asked if there were any projects that WCE could take on,” Cischke remembers. “The folks at Ford gave us three projects and were super happy with what the students were able to accomplish. What brings the projects to mind, though, is the enthusiasm of the student who approached the company. No one asked the student to see whether Ford had any projects we could work on. Because of the student’s enthusiasm for Enterprise and for engineering and for Ford, they took ownership and the initiative to secure what were some really great projects. And this is very representative of what you see from students every year in Enterprise.”

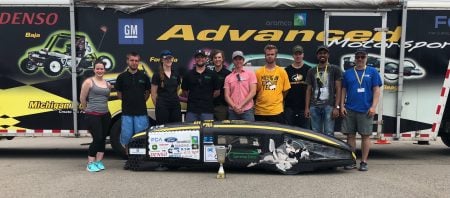

Another project that stands out in Cischke’s mind is one where WCE students built street lights for campus that were powered entirely by renewable energy. “They got hold of an old street light housing and put in LED bulbs, a special kind of wind turbine, batteries, and a small solar panel. They pulled all these different technologies together, harnessed both wind and solar, and stored the energy in a battery to power a highly efficient bulb for a street lamp.”

Cischke notes that the nature of the Enterprise program is to bring in individual student projects funded by external companies. For WCE, this is often companies like Ford, ITC, Stellantis, and Samsung.

“External companies ask Enterprise to work on projects, but what many people don’t realize is that we also have a number of internal projects,” Cischke says. “As far back as the start of Enterprise, one of the ideas was to create royalty-generating intellectual property. Only a couple of projects have gotten that far, but it’s always one of our goals. In the recent past, WCE created a smart circuit breaker that, when tripped, would send a notification to your phone, and you could reset the breaker from your phone. The students who built it were able to demo it for the power industry and came very close to commercialization.”

It’s experiences like that, Cischke says, that demonstrate the program’s value.

“The experience gained from Enterprise is so useful in the real world, because it’s so much like working in a professional setting. The practical experience is so powerful. I would imagine that most stories Enterprise students tell during job interviews come from Enterprise experiences – teamwork, entrepreneurship, budgeting, etc.”

When asked about receiving one of the inaugural Distinguished Service Awards, Cischke says, “It has been an honor to be a part of what I think is one of the most distinguishing aspects of engineering education at Michigan Tech. Watching the students do what they do has been a reward in and of itself. There are a lot of former Enterprise students who have gone on to do amazing and, in some cases, very big things, and to be a part of that as an advisor – and to receive recognition for what goes into advising – is icing on the cake.”

He continues, “One thing that continues to amaze me about Enterprise is how much student leadership there is. The fact that anything has happened at all is due to the fact that students take ownership of the entire organization. It is so fulfilling to see students rise up to take on the administrative aspects of their projects. They take the initiative to make sure things happen. The fact that they self-organize, self-regulate, and self-administer is part of what makes it joyful as an advisor. It is just so cool to watch them step up and grow and mature over time. They walk in the door as students, not quite sure what to do, and they walk out the door engineers ready to hit the ground running.”

About the Enterprise Program

Michigan Tech’s Enterprise Program offers students a unique, hands-on learning experience that goes beyond the classroom. With more than 25+ Enterprise teams spanning disciplines such as engineering, business, computing, and science, students collaborate on real-world projects sponsored by industry and government partners. Enterprise students develop technical expertise, leadership skills, and teamwork experience—preparing them for success in their careers. Many teams work on cutting-edge innovations, from automotive and aerospace to sustainability and emerging technologies.

Explore the Enterprise Program experience and see how you can get involved! Follow Michigan Tech Enterprise on Facebook, Instagram, and LinkedIn for the latest updates.