Jin W. Choi has been appointed Chair of the Department of Electrical and Computer Engineering at Michigan Technological University, effective July 1, 2022.

Dr. Choi comes to Michigan Tech from Louisiana State University, where he served as the Mark and Carolyn Guidry Professor in the Department of Electrical and Computer Engineering. At LSU, Choi led the graduate program in the Department of Electrical and Computer Engineering, and was director of the BioMEMS and Bioelectronics Laboratory.

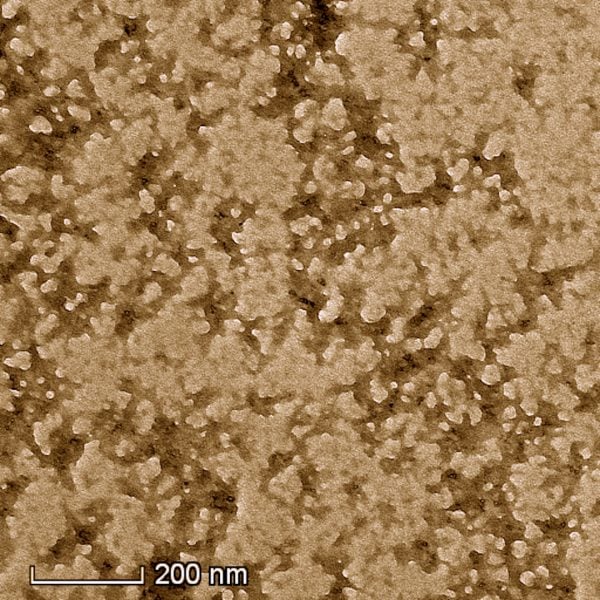

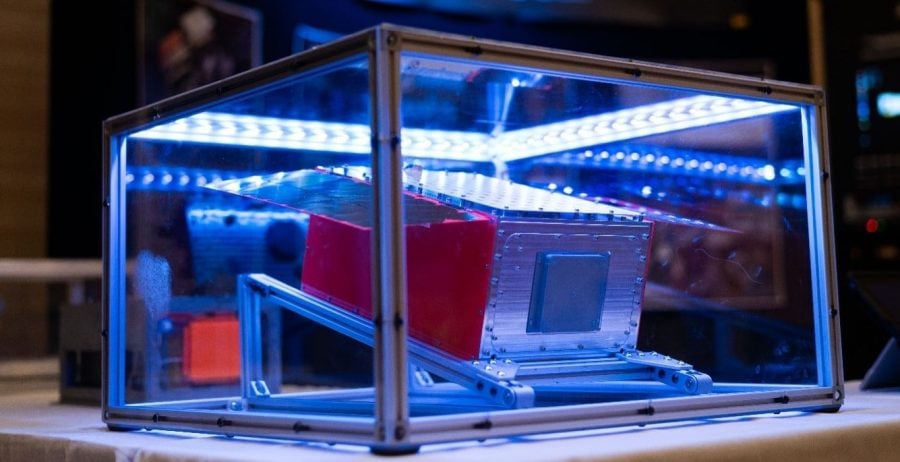

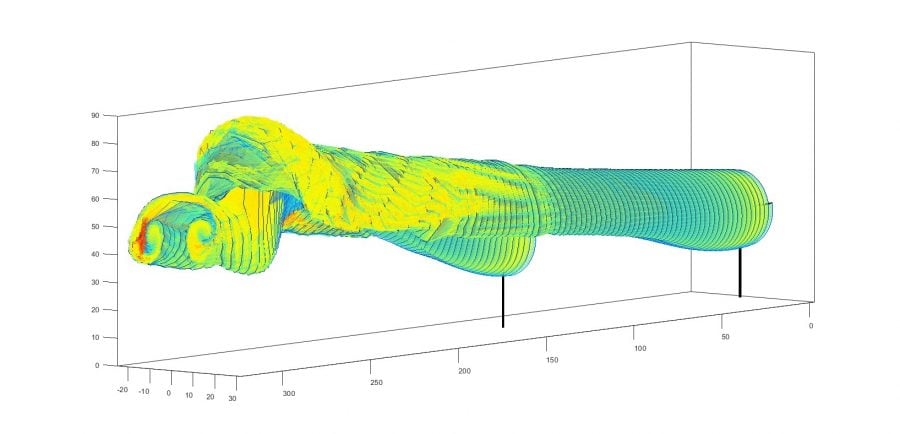

Choi earned his BS and MS in Electrical Engineering at Seoul National University in Seoul, Korea, and his PhD at the University of Cincinnati. His work as a faculty member at Louisiana State University received numerous recognitions for excellence in teaching and mentoring, scholarship, and innovation in engineering research. His research interests include MEMS and BioMEMS, biomedical and bioelectronic devices, microfluidic devices and systems, lab-on-a-chip systems, and various sensors and sensor systems. He holds 8 US patents, including one recently issued to Choi and collaborators for a wireless implantable neural stimulator, designed to help patients with neurodegenerative diseases control pain and improve quality of life.

Janet Callahan, Dean of the College of Engineering, says Choi brings with him a wealth of experience and perspective.

“Dr. Choi’s entrepreneurial approach to research and teaching strongly equips him to carry out the department’s mission of teaching the next generation of electrical, computer and robotics engineers,” says Callahan. “At Michigan Tech he will creatively facilitate the development of technological innovations across a wide field of areas.”

“I am excited to be part of building a better tomorrow with our students, faculty, and staff in the Department of Electrical and Computer Engineering.”

Choi says he was highly drawn to Michigan Tech’s electrical and computer engineering program. He cites several factors that contributed to his decision to move north from Baton Rouge all the way to Michigan’s Upper Peninsula.

“When I came for an interview, I saw great potential for the ECE department to move forward and advance even further,” he says. “The solid and envisioning leadership of the College and the University was strongly encouraging, as well. Most importantly, the motivated students, talented faculty, and supportive staff made me want to join Michigan Tech in this leadership position.”

With Choi at the helm, the ECE department will continue its strong pursuit of excellence in education, research, and service. A primary goal of Choi’s is to promote collaboration within the university, and beyond.

“The horizon of electrical and computer engineering stretches from power engineering to modern and future electronics, space technology, communication and connectivity, computing devices, healthcare, robotics, automobiles, and much more,” Choi explains. “Electrical and computer engineering undoubtedly provide backbone technologies to our modern society as we undergo the 4th industrial revolution. Michigan Tech is patently where a better tomorrow begins.”

“Our goal as engineers is to contribute to our society and to the wellness of human beings.”

At Michigan Tech, the ECE department prepares members of the future workforce and promotes innovative research, notes Choi. “As ECE department chair, I hope to continuously improve the quality of learning—by exploring opportunities for students, assisting students and faculty for their success, and elevating our engagement of alumni and stakeholders to the department.”

Michigan Technological University is a public research university founded in 1885 in Houghton, Michigan, and is home to more than 7,000 students from 55 countries around the world. Consistently ranked among the best universities in the country for return on investment, the University offers more than 125 undergraduate and graduate degree programs in science and technology, engineering, computing, forestry, business and economics, health professions, humanities, mathematics, social sciences, and the arts. The rural campus is situated just miles from Lake Superior in Michigan’s Upper Peninsula, offering year-round opportunities for outdoor adventure.