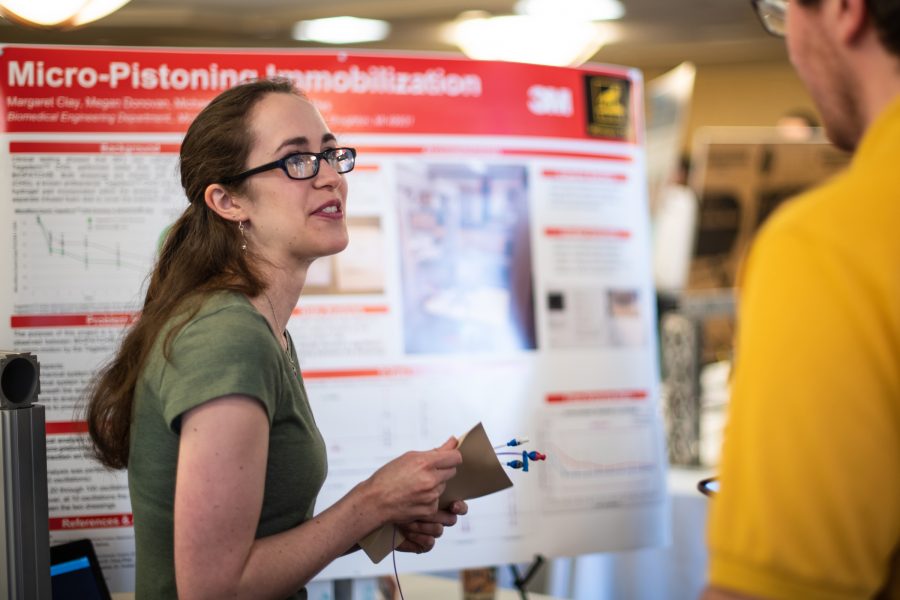

Earlier this month a team of students from Michigan Technological University won the Judge’s Choice for Design in the 2024 National Fluid Power Association Fluid Vehicle Challenge, a national competition.

Competing with 21 other universities from all over the country, the Michigan Tech team set out to design, build, and test a bicycle powered by pneumatics. This requires an in depth understanding of fluid power, pneumatic fittings, and electronic control systems.

The contest, dubbed “Hydraulics, Meets the Bicycle,” combines human-powered vehicles along with fluid power and consists of three races—sprint, endurance, and efficiency.

Despite not winning any races, this year the MTU team was a design champion for the competition.

Lukas Hensely, Cheyenne Goff, Collin Little, Tate Newlin, and Isaac Steers made up the winning team. All are students in Michigan Tech’s Department of Manufacturing and Mechanical Engineering Technology. The fluid-powered bike project also served as their senior design project, required for graduation.

MMET Senior Lecturer David Wanless advised the team. Joe Jackan, Jarp Industries, served as the team mentor. Sponsors this year in addition to NFPA, were Iowa Fluid Power and Jarp Industries.

The competition includes race results, two design reviews, conference participation and a final presentation.