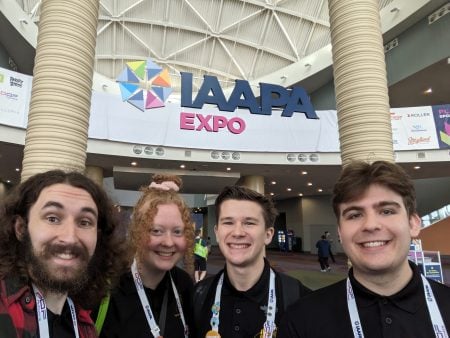

Environmental engineering students from Michigan Tech traveled to New Mexico State University to compete in the 34th annual WERC Environmental Design Contest—and took home numerous awards, $4,000 in prize money, plus the opportunity to be published in IEEE Xplore.

All are members of Michigan Tech’s Built World Enterprise (BWE), part of Michigan Tech’s award-winning Enterprise Program.

For Francine Rosinski, it was her third year in a row competing at WERC, with a different sort of project each time. This year, tasked with creating a stormwater management plan for a disadvantaged community, Rosinski and six other students, Jenna Cook, Allison Olson, Isabel Smith, Nadia Stauffer, Eden Traub, and Andrew Wozniak, created a system of bioretention cells and bioswales employing natural clays and biochar to remove chloride pollution from road salts. Their client? The small, snowy community of Dollar Bay, Michigan, that has been experiencing flooding issues for years.

The WERC Environmental Design Contest was established in 1991 as one facet of a Waste-management Research Consortium (WERC), formed by the U.S. Department of Energy, Sandia National Labs, New Mexico State University, University of New Mexico, and Dine College.

The contest expanded and has continued on for 35 years, inviting undergraduate engineering students from across the country to design solutions for conserving and recycling water, energy, natural resources, and waste.

Each year industry and government agencies propose and sponsor real-world tasks for the contest. The tasks are open-ended, giving teams room for innovation and creativity.

A total of 18 teams competed for prizes this year, including students from Michigan Tech, California Polytechnic State University, Louisiana State University, New Mexico State University, Northern Arizona University, Ohio University, University of Mississippi, University of Arkansas, University of Idaho, Washington State University, and Washington University. Some universities sent more than one team to take part in the contest.

Michigan Tech sent two teams. MTU’s WERC 1 team earned 1st place overall for its green infrastructure stormwater management design, 2nd place for its bench scale demonstration, and received an honorable mention for its business flash talk, basically a quick, 3-minute business pitch. The students dedicated a full academic year to the creation of their green infrastructure stormwater management system for Dollar Bay.

Michigan Tech’s second team, WERC 4, was comprised of all first-year students. The team earned the WERC Judges’ Choice Award for its algal CO2 removal system.

“My favorite part of this project was connecting with the community–spending time attending town hall meetings, meeting with local engineers, and interviewing countless residents on their struggles dealing with ongoing flooding in the town,” said team member Nadia Stauffer, who will graduate this December.

“The competition also gave us time to watch the solar eclipse,” says Roskinski. She graduated in April and recently began work as a water resources engineer in Grand Rapids.

“As an engineer, you will have to work not only with other engineers but also with the community and many other people,” adds Rosinski. “This is what I think sets us apart from other teams in the WERC competition because we addressed specific needs in the community.”

Figuring out how to make an innovative stormwater plan was especially challenging, adds Rosinski. “The competition asked for a nature-based design. There are only so many ways to divert runoff using vegetation or natural materials. We chose to remove a specific pollutant, salinity from road salt and found natural materials that could remove it. This also gave us a competitive edge.”

“College can seem overwhelming and scary at times, but Michigan Tech has prepared us well.”

Besides connecting with the community, participation in WERC provides students with the opportunity to present their findings to knowledgeable professional engineers. “WERC judges offer a great deal of support,” notes Rosinski. “We have received compliments from engineers who said our design was innovative. One judge who has served in the competition for over 30 years told us our poster was one of the best he had seen. Another judge said our writing was great. These opportunities for in-person feedback and professional connections are phenomenal and one-of-a-kind.”

At Michigan Tech, Audra Morse, faculty advisor of Built World Enterprise, encourages undergraduate students of all majors to compete in design competitions and solve problems that relate to civil and environmental engineering. BWE also partners with Engineers Without Borders to provide opportunities for students to collaborate all over the world.

“At Michigan Tech classes are hard, but they push you to be better and to grow, and most importantly, to think critically,” notes Rosinski. “Taking part in Enterprise and BWE enabled me to use the knowledge gained in my classes. I could apply it to real situations while using critical thinking. At the same time, I was also gaining soft skills—public speaking, leadership, and teamwork.”

Rosinski first joined BWE as a second-year student. “Back then I didn’t think I had the knowledge or skills to compete against seniors at other universities for the WERC competition,” she says. “I will never forget being with my team and hearing them call our name for first place for our bench-scale model, then second place for our task. All of a sudden I realized I really could be an engineer, that I do have what it takes to be successful.”

When Rosinski first joined the Built World Enterprise, it was new on campus and smaller with around 15-20 members. BWE has since doubled in size, with over 40 members. Rosinski spent her senior year serving as BWE president.

“Leadership roles are about mentoring and pushing your team to be better, and I strived for that,” she says. “I am so proud, and now I am eagerly waiting to see what BWE does in the future!”