College of Engineering Dean Audra Morse has selected the core first-year engineering faculty team from the Department of Engineering Fundamentals (EF) for the Deans’ Teaching Showcase for their work in developing and delivering an innovative learning experience. The team includes Matt Barron, James Bittner, Gabriel Draughon, Amy (AJ) Hamlin, Brett Hamlin, Michelle Jarvie-Eggart, Amber Kemppainen, Amy Monte and Ken Thiemann, and is supported by staff, students and adjunct instructors who are essential to the team’s mission. The team will be recognized at an end-of-term event with other showcase members and is a candidate for the CTL Instructional Award Series.

The team implements many high-impact practices across 11 sections of ENG1101 and ENG1102, serving 800-1,000 students per semester. Students enter with a wide variety of skills and attributes. The team adopts many strategies to ensure all students develop the knowledge and mindsets needed to succeed in second-year classes associated with 18 different majors.

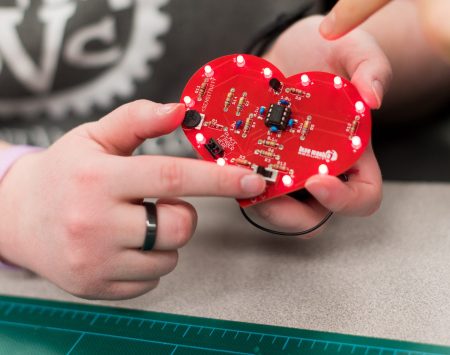

This passionate team of educators continually pushes the boundaries of pedagogy in order to meet students where they are at and support their growth throughout their first year. Their practices include cohort scheduling that places students in several of the same classes together, making it easier to form study groups and friendships; flipped classrooms that foster hands-on learning during class time; and undergraduate near-peer mentors from the innovative LEarning with Academic Partners (LEAP) program who support the active learning environment.

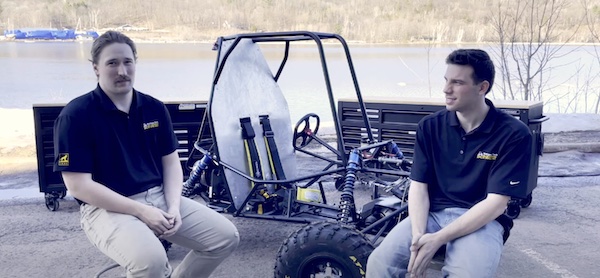

The team embraces the Kern Entrepreneurial Engineering Network (KEEN) framework, which fosters a mindset of curiosity, building connections across disciplines and creating value for others. By using project-based learning and design thinking, students identify opportunities, design solutions using the tools and mindsets of engineering problem solving, and build and test prototypes.

“The EF team is a role model for collaborative instructional teams,” noted Mary Raber, EF’s department chair. “Everyone has participated in professional development opportunities such as entrepreneurial-minded learning, design thinking and inclusive STEM teaching to build their educational skill set. Together, they create an inspiring and dynamic learning environment for students while supporting their growth and development as first-year college students.”

Student evaluations reflect the team’s positive impact, with typically high ratings and positive feedback that includes comments such as, “I really enjoyed your enthusiasm towards the curriculum and found it very helpful that you would sit down and work through something if I had a question,” and “The enthusiastic and engaging energy you bring to the class gives a boost of energy and makes me feel more motivated,” and “Your enthusiasm and interest in our learning was great and the hands-on activities and team projects allowed a lot of room for creativity and personal interest!”

Morse commended the EF Team for their success. “Their diligence in continually innovating the first-year engineering program is phenomenal and key to Engineering’s high first-year retention rate,” she said. “The team constantly looks for ways to help our students succeed, helping them in the critical transition into college, and building their skills so they can be successful in their major.”

By the Jackson Center for Teaching and Learning.