Lyon (Brad) King shares his knowledge on Husky Bites, a free, interactive webinar this Monday, May 18 at 6 pm. Learn something new in just 20 minutes, with time after for Q&A! Get the full scoop and register at mtu.edu/huskybites.

Turning dreams into reality is a powerful motivator for Lyon (Brad) King. He’s the Richard and Elizabeth Henes Professor of Space Systems in the Department of Mechanical Engineering-Engineering Mechanics, and leader of Michigan Tech Aerospace—a collection of research, development, and educational labs dedicated to advancing spacecraft technology.

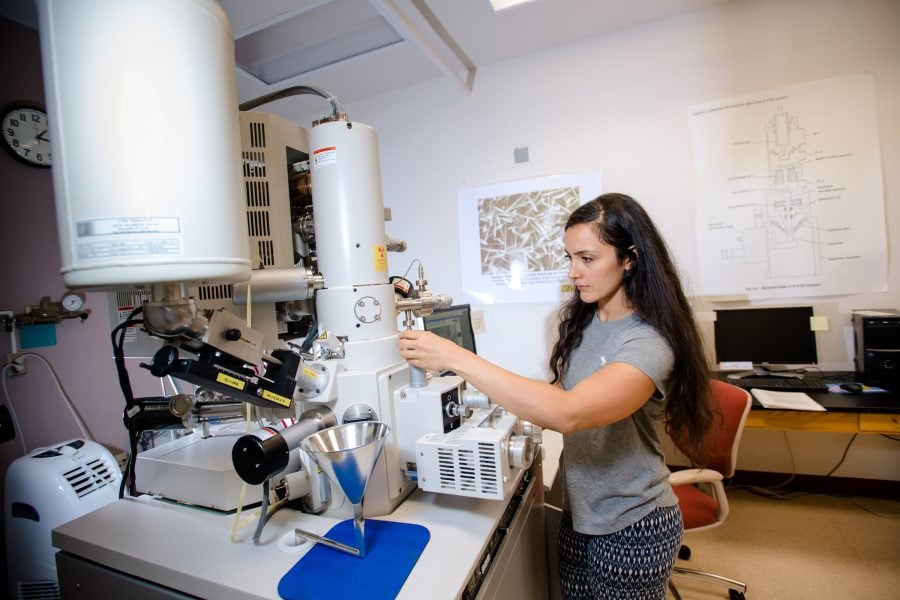

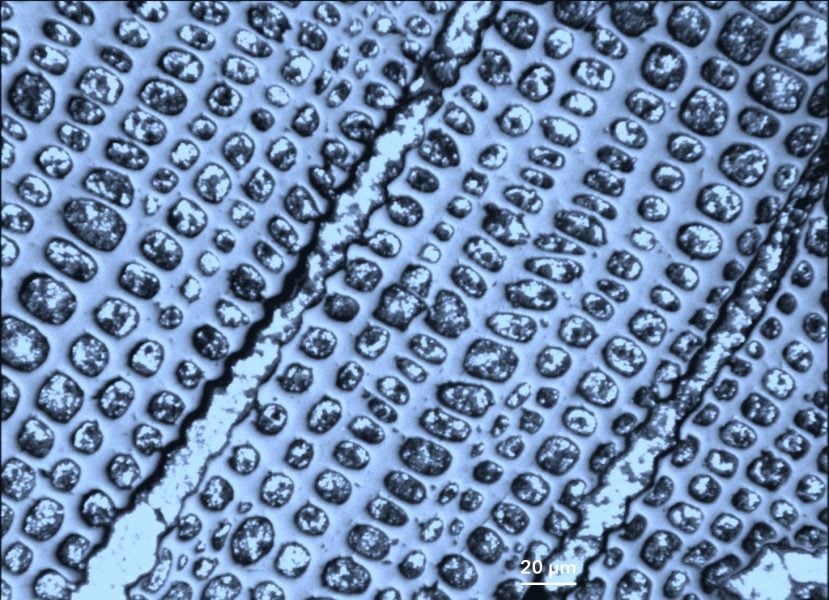

King specializes in spacecraft propulsion — and the launching of student careers. He mentors a large team of graduate students in his research lab, the Ion Space Propulsion Lab, where teams develop next-generation plasma thrusters for spacecraft. Off campus, at the MTEC SmartZone, King is cofounder and CEO of the fast-growing company, Orbion Space Technology.

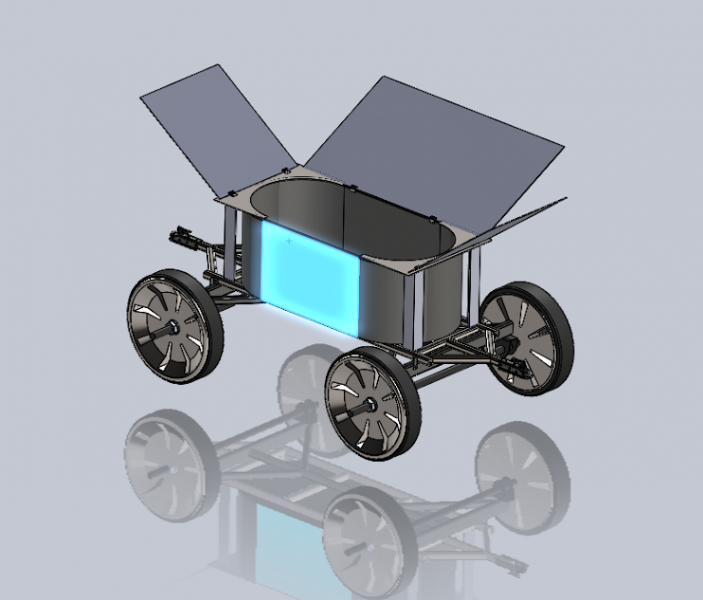

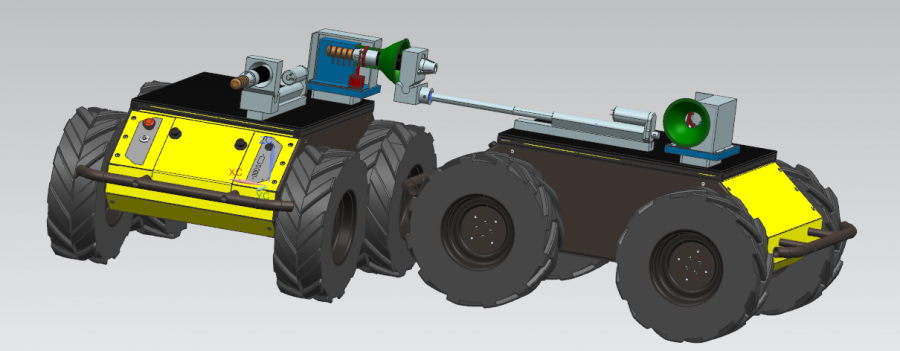

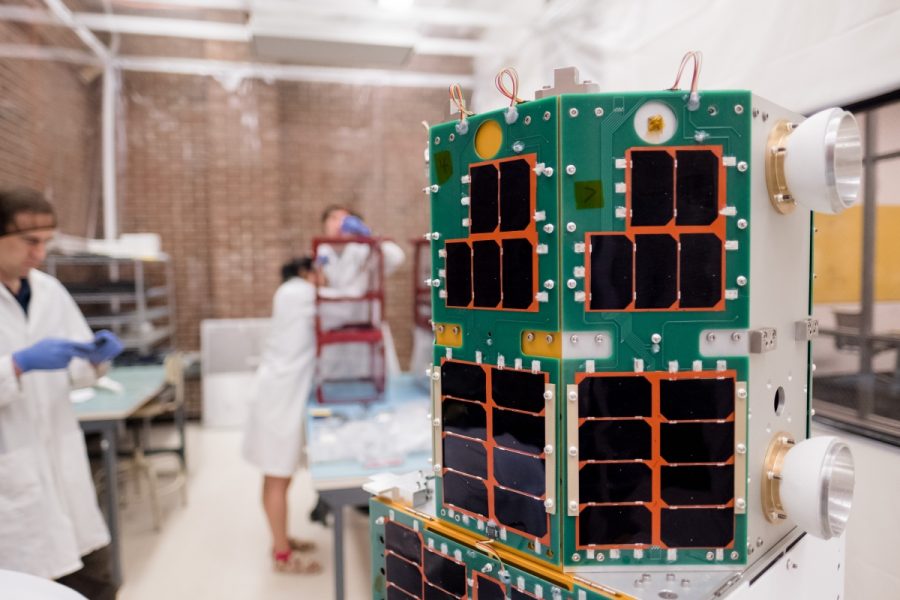

As the founder and faculty advisor of Michigan Tech’s Aerospace Enterprise, King empowers undergraduate students to design, build, and fly spacecraft, too. One of the team’s student-built satellites (Oculus) is now in orbit; their second small satellite (Stratus) is due to launch in March 2021, and a third (Auris) now in process.

“The desire to explore space is what drives me. Very early in my studies I realized that the biggest impediment to space exploration is propulsion. Space is just so big it’s hard to get anywhere. So I dedicated my professional life to developing new space propulsion technologies.”

King has served as the Enterprise advisor ever since a couple of students came to him with the idea to form a team nearly two decades ago. “My current role now is more that of an outside evaluator,” he says. “The team has taken on a life of its own.”

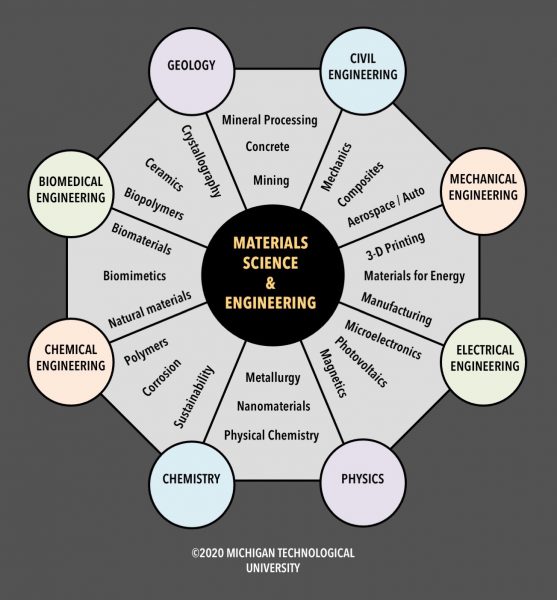

Like all Enterprise teams at Michigan Tech, Aerospace Enterprise is open to students in any major. “It’s important for students to learn how to work in an interdisciplinary group,” says King. “In the workplace, they will never be on a team where every member has the same expertise. To design, build, manage and operate a satellite requires mechanical, electrical, computer science, physics, materials, everything — it really crosses a lot of boundaries and prepares them for a career.”

Adds King: “Michigan Tech has a history and reputation for hands-on projects, particularly its Enterprise Program. Our students don’t just write papers and computer programs. They know how to turn wrenches and build things. That’s been deeply ingrained in the University culture for years.”

Last, but not least: “Aerospace Enterprise has a leadership and management hierarchy that is self-sustaining,” says King. “Current leaders are constantly working to mentor their successors so we have continuity from year-to-year.”

“Dr. King provides excellent mentoring and high-level direction, but does not give students all the answers. It’s up to the students to figure it out. We work in small teams, which forces us to take on more responsibility. We’re thrown off the deep end. It’s hard, but worth it.”

The New Space Era

Commercialization is driving aerospace expansion in Michigan and across the nation. “We were ahead of it,” says King. “We certainly were feeding it and played a part in causing it. MTU’s products — which are our graduates — are out there, making this happen.” Aerospace Enterprise alumni are engineers, managers, technology officers and research scientists in a diverse array of aerospace-related industries and institutions, from the U.S. Army, U.S. Air Force and NASA to SpaceX, both startups and major manufacturers. King himself has hired several of his former students at Orbion Space Technology.

Q: When did you first get into engineering? What sparked your interest?

A: I have always been interested in building things — long before I knew that was called “engineering.” I don’t recall when I became fascinated with space but it was at a very early age. I have embarrassing photos of me dressed as an astronaut for halloween and I may still even have an adult-sized astronaut costume somewhere in my closet — not saying. The desire to explore space is what drives me. Very early in my studies I realized that the biggest impediment to space exploration is propulsion. Space is just so big it’s hard to get anywhere. So I dedicated my professional life to developing new space propulsion technologies. There is other life in our solar system. That is a declarative statement. It’s time that we find it. The moons of Jupiter and Saturn hold great promise and I’m determined to see proof in my lifetime.

Q: Can you tell us more about your growing up? Any hobbies?

A: I was born and raised just north of Houghton (yes, there actually is some habitable environment north of Houghton). I received my BS, MS, and PhD from the University of Michigan. I spent time traveling around the country working at NASA in Houston, NIST in Boulder, and realized that all of my personal hobbies and proclivities were centered around the geography and climate of northern Michigan. I returned in 2000 and began my career as a professor at MTU. I enjoy fishing, boating, hockey, and spent more than 15 years running my dogsled team all over the Keweenaw Peninsula.

Michigan Tech’s Three Student-Built Satellites

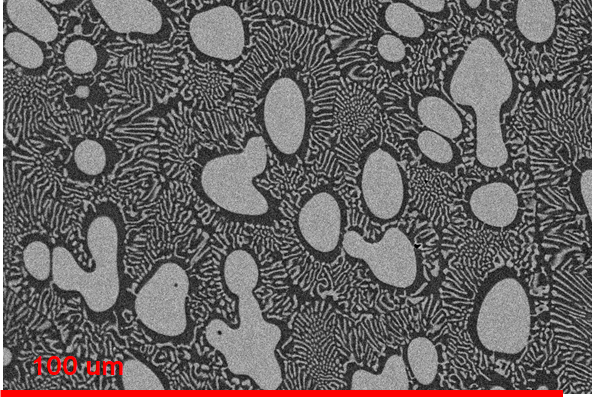

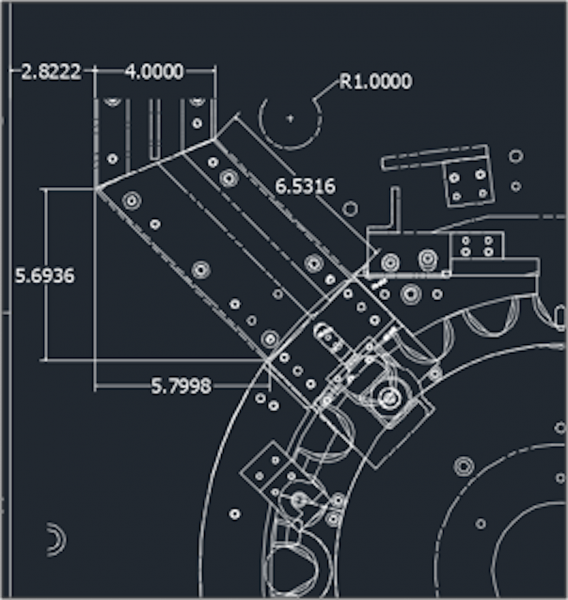

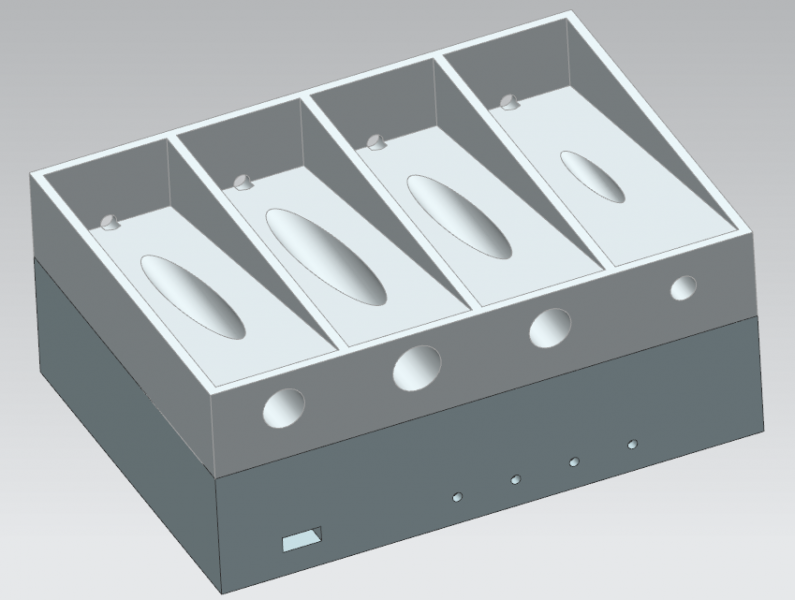

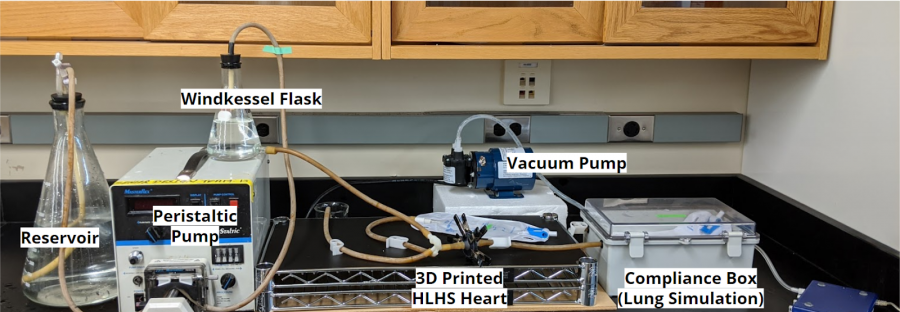

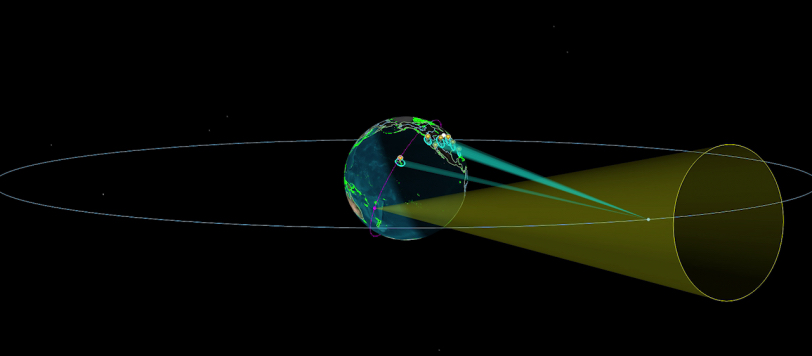

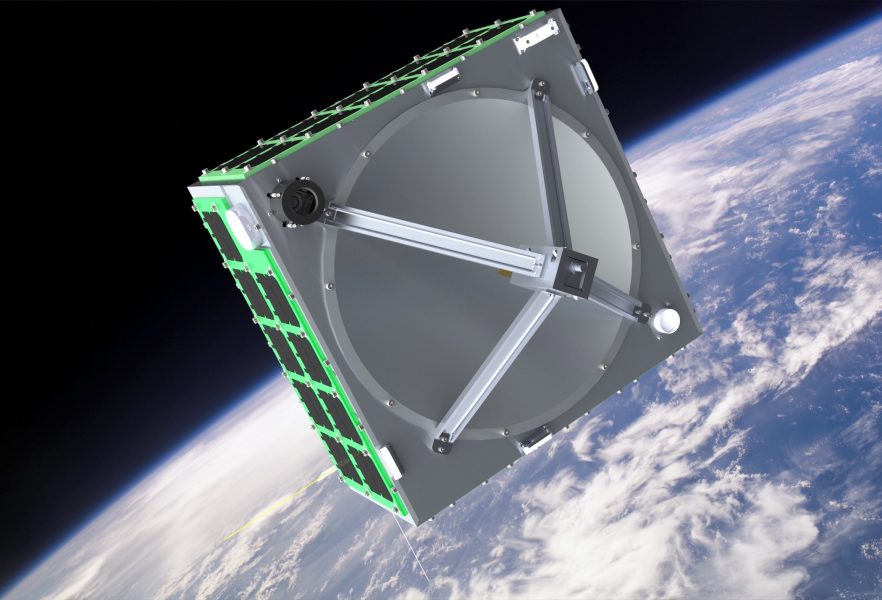

OCULUS-ASR, a microsatellite now in orbit, provides new info to the Air Force. “It is the first satellite mission dedicated to helping telescope observatories understand what they are imaging using a cooperative target. “It’s a very capable little vehicle. There’s a lot packed into it.”

STRATUS, a miniaturized satellite, will image atmospheric clouds to reconcile climate models. It’s funded by NASA’s Undergraduate Student Instrument Program and the CubeSat Launch Initiative. STRATUS will be carried to the International Space Station inside the SpaceX Dragon cargo capsule by a Falcon 9 rocket. The Dragon will dock to the ISS where STRATUS will be unloaded by the crew. STRATUS will then be placed in the Kibo Module’s airlock, where the Japanese Experiment Module Remote Manipulator System robotic arm will move the satellite into the correct position and deploy it into space. All this on March 21. Stay tuned!

AURIS, a microsatellite, is designed to monitor and attribute telecommunications signals in a congested space environment. Funding comes from the Air Force Research Lab (AFRL)’s University Nanosatellite Program.

Huskies in Space

Learn more about the team and its missions on Instagram and Facebook.

Find out how to join.

Read more about Aerospace Enterprise in Michigan Tech News:

And Then There Were Two: MTU’s Next Student Satellite Set to Launch in 2021

Enterprise at MTU Launches Spacecraft—and Careers

Countdown. Ignition. Liftoff. Huskies in Space!

Mission(s) AccomplishedMichigan Tech’s Pipeline to Space

Winning Satellite to be Launched into Orbit