The Aerospace Enterprise, under the direction of Dr. Brad King, is launching satellites as well as student careers. At the University Nanosatellite Program, sponsored by the Air Force Research Lab (AFRL) in August, ten students from the Enterprise team presented their latest satellite application, Auris, to judges from several space-related agencies.

The challenge for the competition was to develop a satellite mission that is relevant to both industry and the military. Students conceived of the idea for Auris, a ‘listening satellite,’ through discussions with Enterprise alumni working in industry and their interest in monitoring communication from other satellites to estimate bandwidth utilization.

“Ten university teams were in attendance and of the teams, we were among three of the schools to be selected to move forward. We now move on to ‘Phase B’ of the program and have a guaranteed launch opportunity with substantial funding to complete the design and integration of our spacecraft,” says Matthew Sietsema, Chief Engineer for the Aerospace Enterprise.

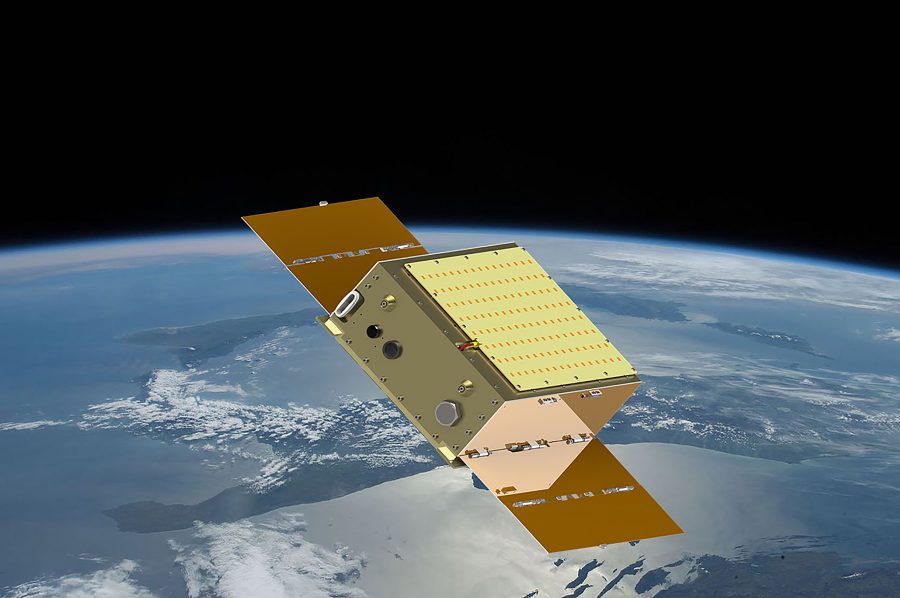

As a result of this award, the Aerospace Enterprise will soon have three satellites in space. Stratus, a climate monitoring satellite that determines cloud height and cloud top winds, was set for a March 2021 launch date. However, it was delayed due to the pandemic and is planned for launch in 2022. Oculus, an imaging target for ground-based cameras for the Department of Defense, was launched in June 2019.

“The Enterprise has remained on the same trajectory and has been very successful by all measures,” remarks King. “Students do a great job managing themselves and the leadership to replace themselves as they graduate and new members move up. It’s a challenge to juggle more than one satellite, but our students have remained focused and hard working while managing several projects and it’s a testament to their tenacity.”

Creating real-world, hands-on learning opportunities for around 100 students per semester, the Enterprise serves as a stepping stone for many as they launch their careers.

“Our students, even if they aren’t in leadership roles, do well securing positions in the aerospace industry. We tend to perform well because we offer a three-year, long-term program, which allows our students to maintain the situational knowledge required to solve complex problems.”