Marty Lagina and Bill Predebon generously shared their knowledge on Husky Bites, a free, interactive Zoom webinar hosted by Dean Janet Callahan. Here’s the link to watch a recording of his session on YouTube. Get the full scoop, including a listing of all the (60+) sessions at mtu.edu/huskybites.

What are you doing for supper this Monday night 11/23 at 6 ET? Grab a bite with Dean Janet Callahan and Marty Lagina, CEO of Heritage Sustainable Energy, winemaker, and creator and star of the long-running reality TV show, Curse of Oak Island.

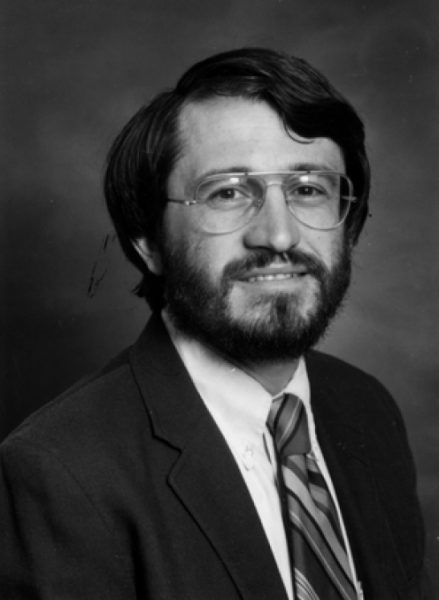

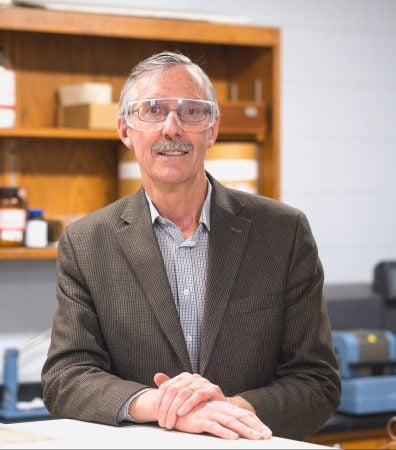

Joining in as Dean Callahan’s co-host will be Bill Predebon, the JS Endowed Department Chair of the Department of Mechanical Engineering-Engineering Mechanics at Michigan Tech.

Lagina is one of Dr. Predebon’s former students—as an undergraduate student in mechanical engineering, Lagina worked as his research assistant.

“If there’s ever been a human being, who if you cut him he bleeds Michigan Tech, that’s Bill Predebon,” says Lagina.

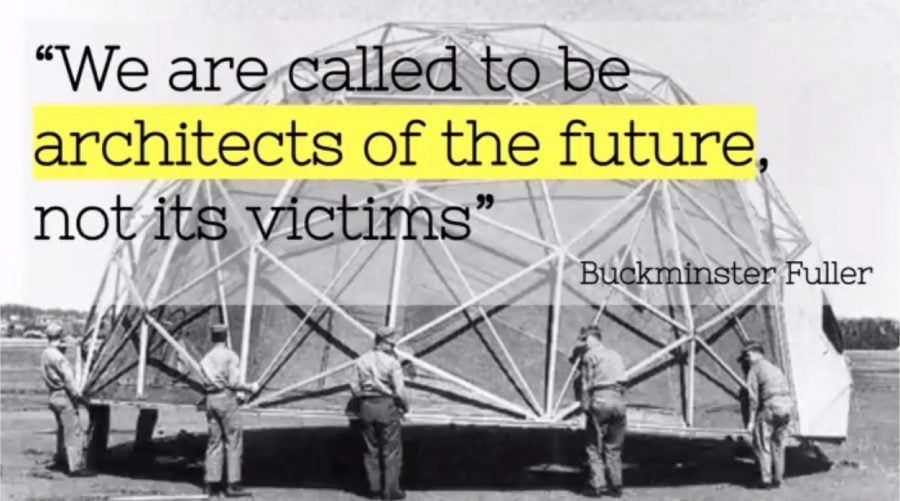

Throughout his life, Lagina says his engineering education has given him the confidence to try new things.

“I was thinking of going to law school, and my father told me: ‘You would make a better lawyer if you knew how things worked.’ So I went to Michigan Tech to study engineering and I liked it. And it prepared me very well for what turned out to be a very multifaceted career.”

“When something interesting comes along, and it looks like fun, and it’s legal and ethical (even better if it’s good for society) and you might make some money—do it!”

Lagina graduated from Michigan Tech with his mechanical engineering degree in 1977, then took a job as a petroleum engineer for Amoco. A few years later, while attending law school at the University of Michigan, he worked as an independent petroleum engineer consultant, hired by various Michigan corporations to explore wells. “I was a law student, putting together oil deals, working out of a tiny room the size of a small walk-in closet,” he recalls.

“Our first 14 lost money, then we finally hit a decent well. It put us in business.” His partner in that first energy consulting business: Craig Tester, another Michigan Tech mechanical engineering graduate. They were college roommates.

Once Lagina earned his JD, the two founded Terra Energy to pioneer the exploration and development of the Antrim shale natural gas resources of Michigan, which they did—successfully developing over $3 billion of oil and natural gas resources.

When he turned 40, Lagina decided to change course. He formed Heritage Sustainable Energy, a renewable energy provider. Heritage has successfully developed a series of wind and solar projects in Michigan, installing enough capacity to power the equivalent of 57,000 average Michigan homes every year.

Heritage operates a total of 139.2 megawatts (MW) of installed renewable energy capacity, with hundreds of MW in its project pipeline, along with a commitment to help reduce Michigan’s dependence on conventional energy sources.

In 2006, Lagina started doing some unnatural exploring to solve a 200–500 year old mystery. Featured on the History Channel, Lagina, his family and friends attempt to solve the “Curse of Oak Island,” based on the legend of a Nova Scotia island.

“I’m the skeptic,” says Lagina. “My brother, Rick, is the optimist, but I’m the engineer who needs more proof.”

Part National Treasure, part Indiana Jones, the five-segment series follows their exploits as they attempt to—literally—get to the bottom of the ‘money pit’ on the island that has given up some clues, booby traps, bizarre hints and puzzle pieces. Theories of what is buried range from treasures from Solomon’s temple, the Holy Grail, the Knights Templar, or pirates.

First, they had to spend millions to purchase a controlling interest in the North Atlantic island. “And everything is difficult,” Lagina says. “It’s been dug at for 200-plus years, so you need to figure out if you are discovering something from the original works or not.”

Tester, an expert on drilling, resistivity, and more, also appears on The Curse of Oak Island.

Born in Kingsford on Michigan’s Upper Peninsula, Marty has spent nearly all his life living in Michigan. His background is in engineering and the energy business, but with family ties to one of Italy’s premier winegrowing areas, a passion for wine is in his blood.

He founded Mari Vineyards in 1999 (the same year he was inducted into Michigan Tech’s ME-EM Academy). His goal: to make world-class red wines in northern Michigan but with a nod to the Italian style of his ancestors. The winery’s namesake is Lagina’s Grandma Mari, an Italian immigrant who settled in the Iron Mountain area of Michigan’s Upper Peninsula. Lagina is said to have fond memories of her creating wine in the basement of her home.

Mari Vineyards is situated on 60 acres in Traverse City. The winery is 100 percent carbon neutral and built from UP dolomite stone, dug from the bases of wind turbines. Lagina has unique growing methods, too—something he plans to share during his session of Husky Bites. As for the wine? “It’s good!” he says.

“Winemaking is an art, but it’s also highly technical,” he adds. “My education at Michigan Tech is what gives me the confidence for innovation.”

Dr. Predebon, what do you do in your spare time?

“I’ve been at Michigan Tech since 1975. That’s 45 years this fall. I just finished 22 years as department chair. My work has absorbed my life, by choice. I have a real passion for our program. We do a good job of preparing engineers, with a heavy emphasis on hands-on education.

“I have always enjoyed teaching, so the way I look at my role is to nurture the growth of my faculty and staff, right along with our students. I want to help them all reach their potential.

“That said, exercise is a big part of my life, too. I try to exercise every day. I mainly run on a treadmill and lift weights. My wife is an artist and a potter, and together we organically garden. Turns out you can grow anything here in the UP. My wife is very good; I just help. We have a peach tree, we have grown watermelon, we’ve grown cantaloupes, we’ve grown potatoes, her passion is pumpkins so we grow these large pumpkins—150 pounds.”