In celebration of its 25 years at Michigan Technological University, the Enterprise Program has awarded eight inaugural Enterprise Distinguished Service Awards to recognize the dedication and exceptional contributions of advisors and champions who have played pivotal roles in shaping the program’s success. The recipients of the Enterprise Distinguished Service Award are Brett Hamlin, Glen Archer, Rick Berkey, Jason Blough, Brad King, Robert Pastel, Tony Rogers, and Christopher “Kit” Cischke.

Each of the award winners has more than 15 years of service within Enterprise, dedicating their time and expertise to guide teams, ensure student success, and advance the program’s discovery-based learning mission. The eight advisors have also fostered industry collaborations and strengthened the bridge between academia and industry.

This eight-part series highlights the contributions of each award recipient.

Clean Snowmobile Team Faculty Advisor

Jason Blough, chair and distinguished professor in the Department of Mechanical and Aerospace Engineering, has advised the SAE Clean Snowmobile Enterprise since 2006.

“Prior to joining the mechanical engineering department, I worked at the Keweenaw Research Center for about five years,” Blough recalls. “I ran a noise and vibrations group, and one of the projects I worked on while I was there was helping to redevelop and understand the noise testing procedures for snowmobiles.”

Blough became a member of the SAE snowmobile committee, which establishes the testing standards snowmobiles must meet in order to be sold in North America. Many of the standards the committee established were adopted by Europe as well.

“I got involved with the snowmobile industry to help them make quieter snowmobiles and do a better job testing them,” Blough says. “When I joined the faculty at Michigan Tech, the Clean Snowmobile Enterprise already existed, but the faculty advisor left shortly after I joined, so I took over. There were a lot of reasons for me to take it over, and it just made sense — I had contacts in the snowmobile industry and had already been working on snowmobiles. Plus, I’m a noise and vibrations person, and one of the goals of Clean Snowmobile is to make them quieter.”

For Blough, one of the best aspects of the Enterprise Program is the continuity – students are members for at least two years, and most stay on for three years or longer.

“You get to actually build a relationship with students. In a classroom setting, you see them for a semester and then they move on. But with Enterprise, I get to know them well enough that they open up about their lives, and we joke around together. I get to build a different kind of relationship with them, and it’s much more enjoyable.”

Blough has had students join Clean Snowmobile during the second semester of their first year and continue on through their fifth year. “They grow and mature throughout the experience, and you get to see it. When you’re working with students every week, you get to see them change and mature, and take on leadership roles. It’s very rewarding. The relationship you build is strong enough that you still talk with them years after they’ve graduated.”

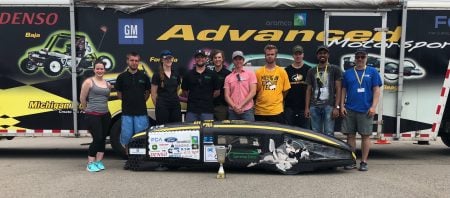

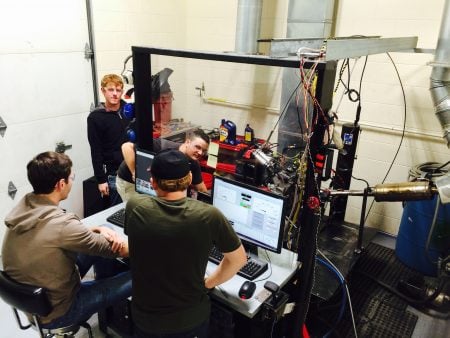

When asked about standout experiences and memories, Blough recalls the SAE International Clean Snowmobile Challenge (CSC) of 2021. CSC is a competition where student teams from participating universities reengineer existing snowmobiles to reduce emissions and noise. The teams then compete in a variety of events that test, among other things, emissions, noise, fuel economy/endurance, and acceleration. In 2020, CSC was canceled halfway through the competition due to the COVID-19 pandemic; in 2021, the event was 100 percent virtual and simulation-based. In other words, competitors needed to simulate riding and test conditions.

“We had created a practice curriculum around 2016 for mechanical and aerospace engineering and had included a lot of simulation into the engineering practice courses. When the students found out that the 2021 CSC would be an entirely simulation-based competition, the mechanical engineering students grabbed the bull by horns and said, ‘We know how to do this stuff.’ And in 2021, Michigan Tech won every aspect of the entire competition. We won for both diesel and spark-ignited engines, and we won all of the sub-competitions — best performance, best design, etc. We won every category.”

The team has also seen its share of disappointment. “In 2010, we were leading the competition,” Blough remembers. “All we needed to do was finish the last event with our gasoline sled and we would get first place. Well, the battery cable came off about 8 feet from the finish line. The cable came off, the sled stopped moving, and that was it. It was a real heartbreaker,” Blough says with a laugh. “We were so close!”

In addition to advising the Clean Snowmobile Enterprise, Blough also served as the SAE student chapter advisor from 2004 to 2021. In that role, he provided support to the Formula SAE, Baja, and Supermileage Enterprises in addition to Clean Snowmobile. Blough has also been a member of the Enterprise advisory board for as long as he’s been advising, helping shape the direction of the program. To receive the Distinguished Service Award feels like an acknowledgment and a thank you for being with the program for so long and in different facets.

“It’s a really nice nod of appreciation after putting in the time over the years to support the students,” Blough says. “It’s been rewarding. I’m a strong advocate for the Enterprise Program in all its forms and for all its teams. It gives our students an opportunity that they can’t get anywhere else — to get academic credit and also leadership experience and growth. For some of these students, by the time they’re juniors and seniors, they’re leading a group of 25-50 students or more. And the students truly lead the group. It’s a fabulous experience for them, and I’ve done and will continue to do everything I can to support it.”

About the Enterprise Program

Michigan Tech’s Enterprise Program offers students a unique, hands-on learning experience that goes beyond the classroom. With more than 25+ Enterprise teams spanning disciplines such as engineering, business, computing, and science, students collaborate on real-world projects sponsored by industry and government partners. Enterprise students develop technical expertise, leadership skills, and teamwork experience—preparing them for success in their careers. Many teams work on cutting-edge innovations, from automotive and aerospace to sustainability and emerging technologies.

Explore the Enterprise Program experience and see how you can get involved! Follow Michigan Tech Enterprise on Facebook, Instagram, and LinkedIn for the latest updates.