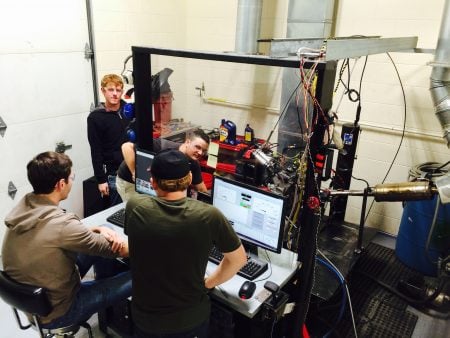

Since its inception, the Enterprise Program at Michigan Technological University has provided students with hands-on, interdisciplinary learning experiences, offering them the opportunity to work on real-world projects that have shaped their futures. Over the past 25 years, the program has seen tremendous growth and success, and its impact is undeniable.

The journey began in 1998 when a three-year National Science Foundation (NSF) grant was awarded to support the pilot program. By 1999, the Enterprise Program was officially launched with just three teams, testing the innovative approach of combining academic learning with practical, industry-driven projects.

In 2000, the program scaled up, welcoming more students and expanding the number of teams. Just a year later, the Formula SAE team achieved a significant milestone by placing 20th out of 123 universities in an international competition. This was only the beginning of many future competitive successes.

By 2002-2003, the program introduced a 20-credit Enterprise minor, further enriching students’ academic experience by allowing them to dive deeper into the intersection of theory and practice. During this period, the program worked to expand its team offerings to be interdisciplinary, providing a comprehensive platform for students to thrive.

Over the years, Enterprise teams have tackled everything from environmental challenges to space exploration. The Aerospace Enterprise stood out by winning the prestigious University Nanosat 6 competition, and in 2019, they successfully launched the Oculus-ASR satellite into orbit, marking a monumental achievement for the university. And that is just a tiny sample of the dynamic history of the Enterprise Program.

Key Milestones in the 25-Year History of the Enterprise Program

| Date | Milestone |

| October 1, 1998 | Three-year National Science Foundation (NSF) grant EEC-9872533 (submitted under the Action Agenda for Systemic Engineering Education Reform) for $749,976 awarded to Michigan Tech. The proposal was titled “Redesigning Engineering Education with Active Learning and Integration Through the Engineering Enterprise (REEALITEE).” |

| 1999 | The Pilot Year – 3 teams are created to test the Enterprise concept. The first teams are Program in Integrated Sustainable Manufacturing (PrISM), Resource Engineering Associates (REA), and Wireless Communication Enterprise (WCE)—which is still operating today! |

| 2000 | Official Enterprise Program launch and scale-up from the successful pilot year—200 enrolled Enterprise students, 11 Enterprise teams, and 19 majors represented |

| 2000 | Blizzard Baja joins the Enterprise Program |

| 2000 | Clean Snowmobile, Consumer Product Manufacturing, Formula SAE, and ITOxygen are formed |

| 2001 | Robotics Systems Enterprise and Automotive Systems Enterprise (later renamed Supermileage Systems Enterprise in 2008) are formed |

| 2001 | Formula SAE places 20th (out of 123 universities) and is runner-up for the Mechanical Dynamics Functional Digital Car Award and 3rd Plade in the TRC Safety and Crash Worthiness Award |

| 2002 | Aerospace Enterprise is formed |

| 2002 – 2003 | New 20-credit Enterprise minor is offered. The Enterprise Program grows to 17 Enterprises, 400 students, and 19 disciplines—76% of teams supported by industries |

| 2004 | Blue Marble Security Enterprise forms as a Wireless Communications spinoff to engage students in homeland security innovations |

| 2004 | International Business Ventures is formed—revisioned into the Innovative Global Solutions Enterprise in 2015 |

| 2005 | Husky Game Development and STC Arts Enterprise (later rebranded as CinOptic Enterprise) are formed |

| 2006 | The new Institute for Interdisciplinary Studies expands Enterprise accessibility to students from all majors—Institute Associate Director Mary Raber, critical to Enterprise growth since its inception, serves as the program’s director |

| 2006 | BoardSport Technologies Enterprise is formed |

| 2009 | Advanced Metalworks Enterprise is formed with the merger of ICE and PrISM, and Green Campus Enterprise and Velovations are formed |

| 2011 | Humane Interface Design Enterprise is formed |

| 2011 | Husky Game Development launches Arcane Brawlers on Xbox Live |

| 2012 | The National Academy of Engineering (NAE) included Enterprise as one of only 29 programs selected nationally in their publication “Infusing Real World Experiences into Engineering Education” |

| 2012 | Nanotechnology Innovation Enterprise wins patent disclosure competitions sponsored by MTU’s Institute for Leadership and Innovation |

| 2012 | Open Source Hardware Enterprise is formed |

| 2013 | Alternative Energy Enterprise is formed |

| 2014 | Enterprise program expands to include graduate students in the program |

| 2015 | General and Expedition Adventure Research (GEAR) is formed |

| 2015 | Multiplanetary INnovation Enterprise (MINE) is formed (originally named the Mining Innovation Enterprise) |

| 2016 | The Enterprise Manufacturing Initiative, sponsored by the GM Foundation is started—It is a cross Enterprise, collaborative group of students interested in learning more about manufacturing while enhancing the manufacturability of a project within their Enterprise team |

| 2016 | Strategic Education through Naval Systems Experiences (SENSE) is formed |

| 2017 | Michigan Tech’s Enterprise Program was selected by the American Society of Mechanical Engineers (ASME) Engineering Education Awards Committee for the Donald N. Zwiep Innovation in Education Award |

| 2017 | Supermileage Systems wins a technical innovation award at Shell Eco-Marathon Americas |

| 2018 | Robotic Systems Enterprise wins 2nd place Concept Design Event in the SAE Auto Drive Challenge competition |

| 2019 | Built World Enterprise (BWE) is formed |

| 2019 | The first satellite built by Aerospace Enterprise is launched by SpaceX at Cape Canaveral as part of the Department of Defense STP-2 mission |

| 2019 | Multiplanetary INnovation Enterprise (MINE) decided to form a team to participate in the NASA Lunabotics Competition |

| 2019 | H-STEM Enterprise is formed |

| 2020 | HotForest Solutions Enterprise is formed—rebranded into Circular Solutions Enterprise in 2024 |

| 2020 | Clean Snowmobile Challenge celebrates 20 years; it’s one of five Enterprise teams involved in the SAE International Collegiate Design Program that impacts more than 10,000 students annually |

| 2020 | Blizzard Baja hosts the 40th annual Winter Baja event at Michigan Tech |

| 2020 | Robotic Systems Enterprise wins 2nd place in the overall SAE Auto Drive Challenge competition. It also wins 2nd place in Social Responsibility Event, 23rd place in Concept Design Event |

| 2020 | BWE participates in the ACRP Student Design Competition and receives First Place for “Runway Intersection Marking” in the Runway Safety/Runway Incursions/Runway Excursions Challenge |

| 2021 | Multiplanetary INnovation Enterprise (MINE) competes virtually in the NASA Lunabotics Competition |

| 2022 | Blizzard Baja sweeps the competition at the Backwoods Baja event at UW Stout |

| 2022 | Innovative Global Solutions (IGS) makes historic trip to Kenya (Africa) to improve the aquaponics system |

| 2023 | Robotic Systems Enterprise wins 2nd place Concept Design Event in the SAE Auto Drive Challenge competition |

| 2023 | BWE’s Timber Strong Team participates in its first competition and wins 3rd place at the Indiana-Kentucky Symposium, setting an ASCE build time record of around 39 minutes |

| 2023 | Multiplanetary INnovation Enterprise (MINE) team’s ARES robot wins the judge’s innovation award as well as the 6th place Caterpillar Autonomy Award in NASA Lunabotics Competition |

| 2024 | The Multiplanetary Innovation Enterprise (MINE) team’s STELLAR robot qualified to go to the Kennedy Space Center Visitor Center for the finals, where it excavated and deposited the third-largest berm |

| 2024 | BWE’s Timber Strong Team participates in 2nd competition at Akron, Ohio, and places 1st overall. The team reset the ASCE national build time record with a time of just over 14 minutes |

And that is just a sample of the dynamic history that makes up the past 25 years of the Enterprise Program!

As we move forward, the Enterprise Program continues to grow, evolve, and offer invaluable opportunities for students to apply their knowledge, develop teamwork and leadership skills, and prepare for successful careers in a variety of industries. This unique program remains a cornerstone of Michigan Tech’s commitment to experiential learning, and its legacy will undoubtedly inspire future generations of students to dream big and make an impact on the world.

As we celebrate 25 years of the Enterprise Program, it’s essential to acknowledge the remarkable experiences it has provided to thousands of students. Are you an Enterprise Program alumni? We would love to hear your story!