Craving some brain food? Join Dean Janet Callahan and a special guest each Monday at 6 p.m. EST for a new, 20-minute interactive Zoom webinar from the College of Engineering at Michigan Technological University, followed by Q&A. Grab some supper, or just flop down on your couch. This family friendly event is BYOC (Bring Your Own Curiosity). All are welcome. Get the full scoop and register—it’s free—at mtu.edu/huskybites.

The special guests: A dozen engineering faculty have each volunteered to present a mini lecture for Husky Bites. They’ll weave in a bit of their own personal journey to engineering, too.

“We created Husky Bites for anyone who likes to learn, across the universe,” says Callahan. “We’re aiming to make it very interactive, with a “quiz” (in Zoom that’s a multiple choice poll), about every five minutes. “Everyone is welcome, and bound to learn something new. We are hoping entire families will enjoy it,” she adds. “We have prizes, too, for near perfect attendance!”

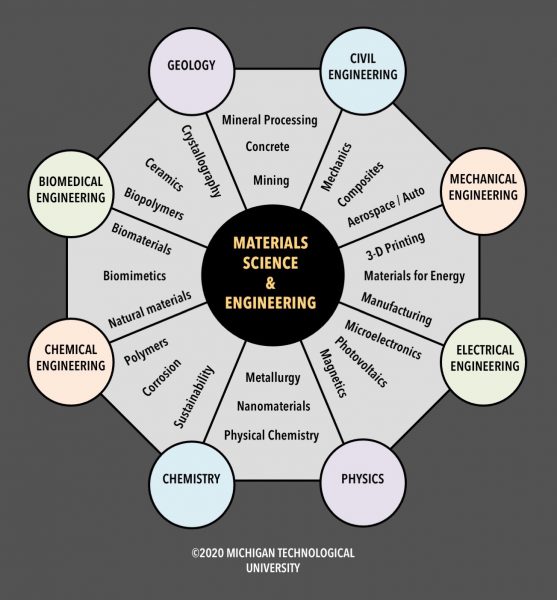

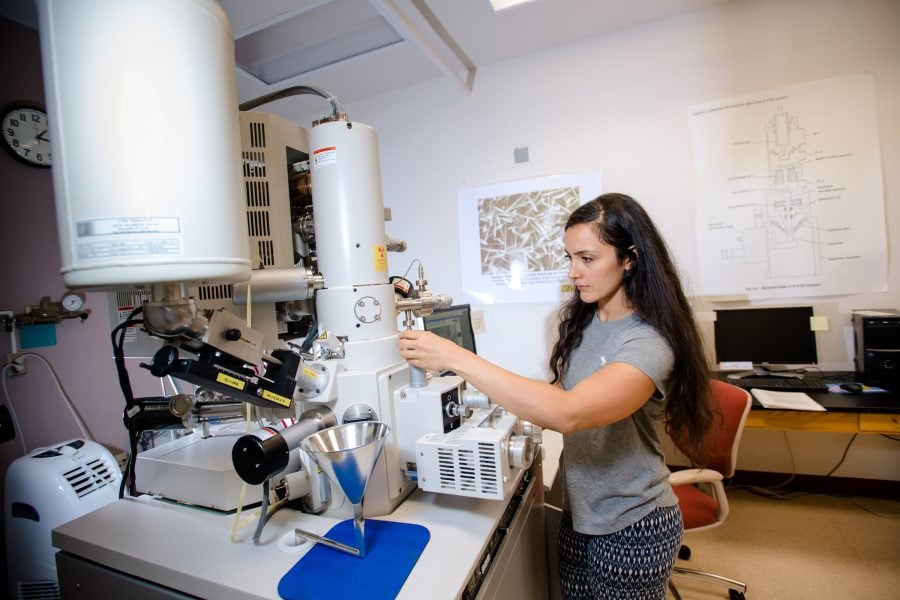

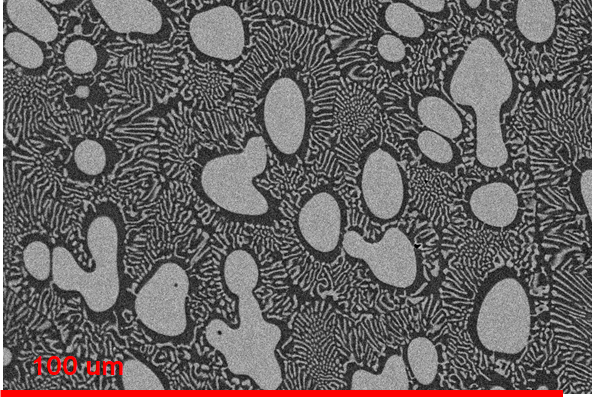

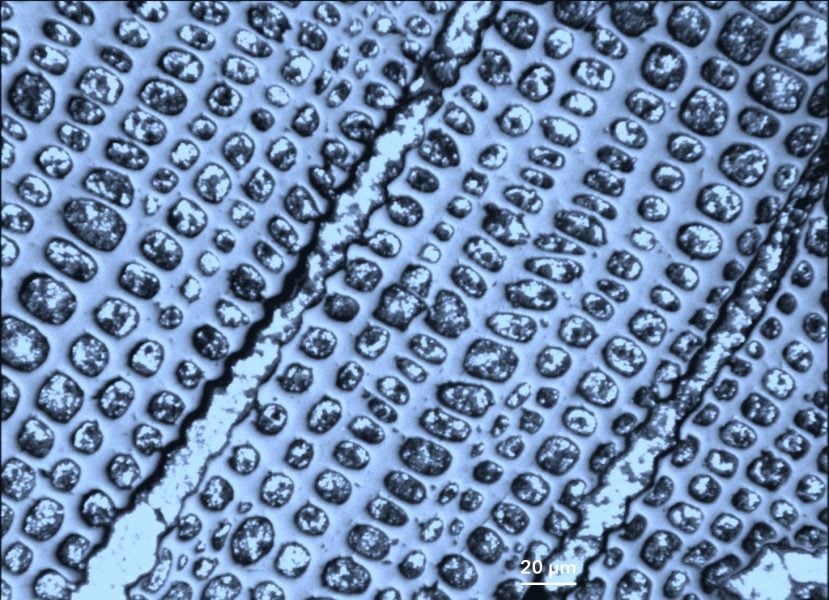

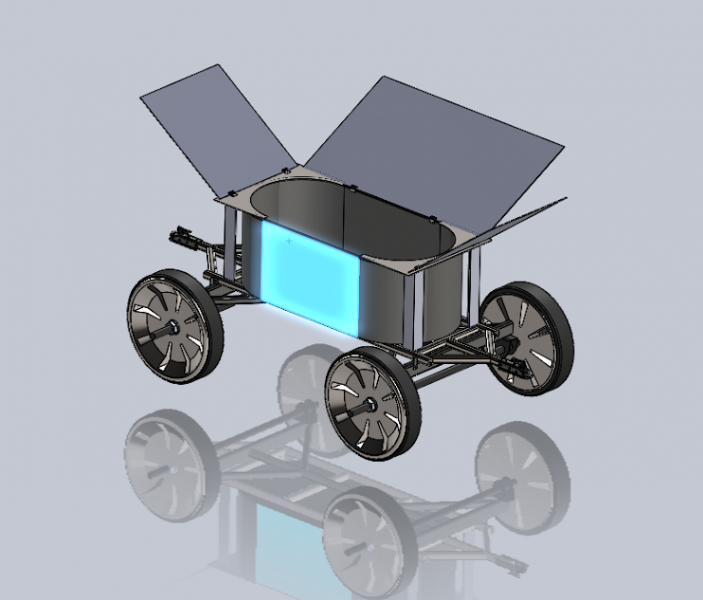

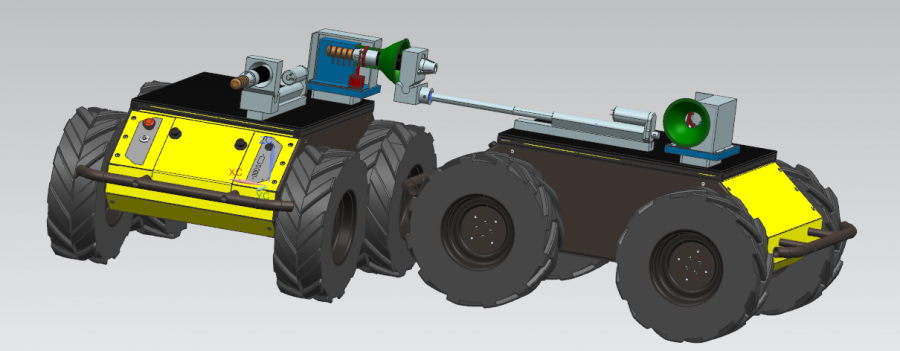

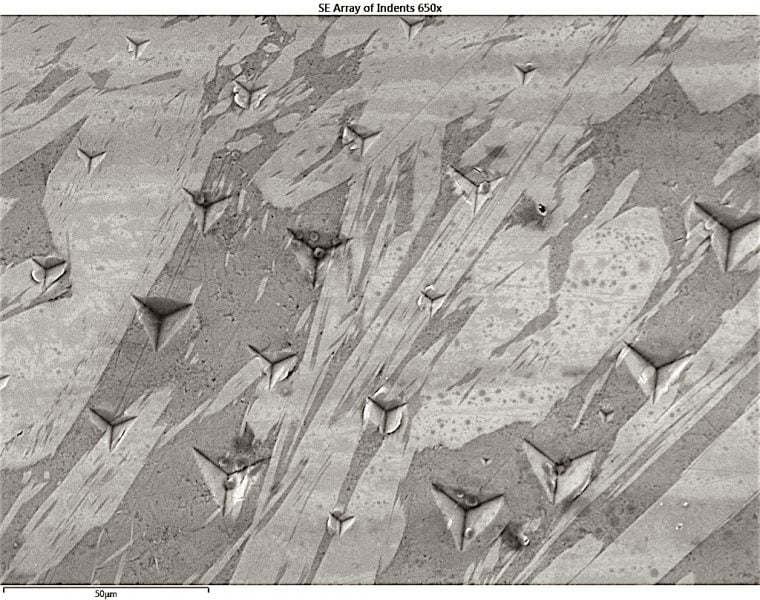

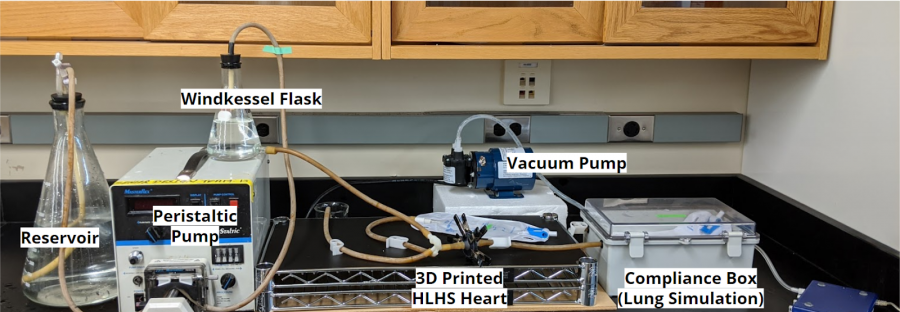

Topics include: Space, Satellites, and Students; Shipwrecks and Underwater Robots; A Quieter Future (Acoustics); Geospatial Wizardry; Color-Changing Potions and Magical Microbes; Scrubbing Water, There’s Materials Science and Engineering, in my Golf Bag, Biomedical Engineering the Future, How Do Machines Learn, Robotics, Math in Motion, and more. Get the full scoop and register (it’s free) at mtu.edu/huskybites.

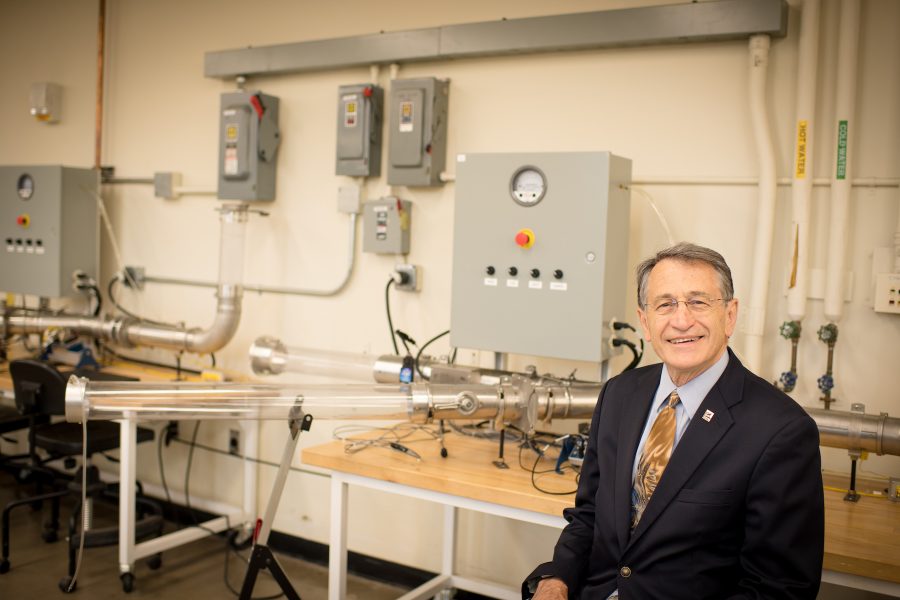

The series kicks off on Monday, May 11 with a session from GMES professor and chair John Gierke, a self-professed “Yooper graduate of the school of hard rocks.”

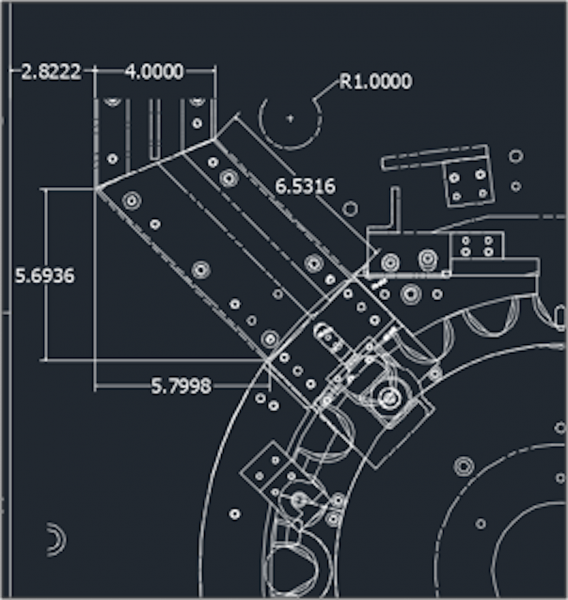

In his Husky Bites session, “How the Rocks Connect Us,” Gierke will talk about how the geology of the Keweenaw is more exposed and accessible. “The experience of spending time in the Copper Country is enhanced if you understand more about the forces of nature that formed this beautiful place,” he says. “The processes that led to the geological formations that lie beneath us and shaped our landscapes are what dictated many of the natural resources that are found where each of us live.” Gierke was born in the EUP (the Soo, aka Sault Sainte Marie) and graduated from Michigan Tech. He will provide practical explanations for why the mines are oriented as they are, where water is more prevalent—and the geological features that lead to waterfalls. You can read all about it here.

Other guests on Husky Bites include engineering faculty L. Brad King, Gordon Parker, Rebecca Ong, Guy Meadows, Andrew Barnard, Tony Pinar, Daisuke Minakata, Jeremy Bos, Joe Foster, Smitha Rao, and Steve Kampe.

Want to see the full schedule? Just go to mtu.edu/huskybites. You can register from there, too.