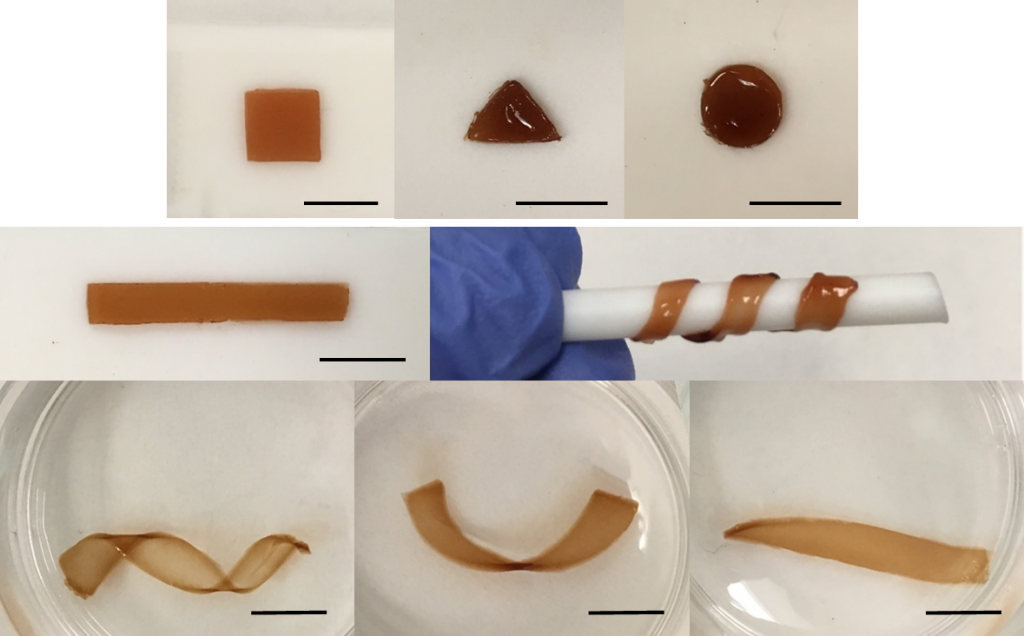

Bruce Lee, an associate professor of biomedical engineering at Michigan Tech, focuses on smart adhesives and biomaterials inspired by nature. More specifically, the natural glues made by mussels that anchor them to rocks, boats and docks. His past work on hydrogels and tissue adhesives led him to look more closely at what makes these adhesives work underwater—and how people could use them.