On April 15, 2025, Michigan Technological University marked a significant milestone with the 25th annual Design Expo—a celebration of innovation, creativity, and collaboration. Over 1,000 students took over campus spaces to present their work, showcasing a wide range of groundbreaking projects developed through Senior Design and Enterprise teams. From sustainable energy solutions and medical technologies to aerospace simulations and infrastructure designs, students demonstrated not only technical excellence, but also a deep understanding of the societal and environmental impact of their work.

Now in its 25th year, the Design Expo continues to be a signature event that brings together students, faculty, industry partners, and the broader community to celebrate the culmination of months—sometimes years—of hard work. The projects on display reflect Michigan Tech’s hands-on, problem-solving approach to education and its commitment to preparing students for real-world challenges.

As part of this landmark year, several teams were recognized for their outstanding achievements. Read on to meet the 2025 Design Expo award winners and honorable mentions who stood out among an exceptional field of competitors. Visit the Design Expo Awards website for the complete project descriptions and videos.

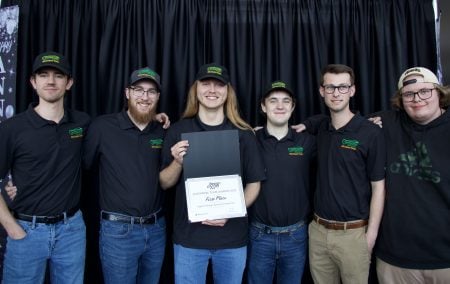

Enterprise Awards

First Place: Team 124 – Supermileage Systems

Led by David VanBuren and Jonathan Watson, this team engineered a high-efficiency vehicle, pushing the boundaries of fuel economy. Their project was guided by advisor Nicholas V. Hendrickson and supported by industry leaders, including General Motors, Aramco Americas, Oshkosh, Halla Mechatronics, and many others.

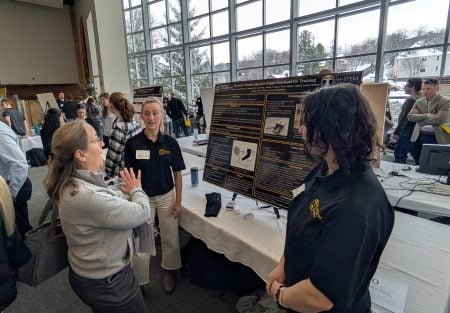

Second Place: Team 119 – H-STEM Enterprise

Under the leadership of Miles Heskett and Amelia Fadoir, the H-STEM team developed innovative healthcare solutions. Advisor Dr. Smitha Rao and the Visser Foundation provided essential support for their endeavors.

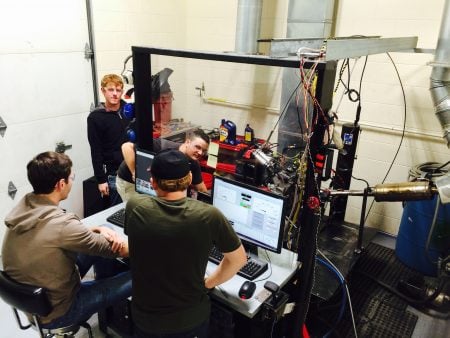

Third Place: Team 123 – Blizzard Baja Enterprise

Lauren Carroll and Liam LaFave spearheaded the design of an off-road vehicle tailored for rugged terrains. Their project benefited from the mentorship of Kevin Johnson and sponsorship from companies that include General Motors, Aramco Americas, CTech Manufacturing, and Milwaukee Tools.

Honorable Mention: Team 113 – Green Campus Enterprise

Caroline Brown and Ray Buenzli led their team, which focused on sustainable campus initiatives aimed at reducing environmental impact. Their work was overseen by advisor Robert Handler and supported by MTU Facilities.

Senior Design Awards

First Place: Team 212 – Crimmins Renewable Energy Distribution

This team, comprising Brett Najmowicz, Emily Moyer, Luke Leslie, Zach Tauriainen, Nicholas Pierce, and Marcus Wu, developed a system for efficient renewable energy distribution. Advisors Trever Hassell and Tony Pinar, along with sponsor Roger Crimmins, played pivotal roles in their success.

Second Place: Team 220 – Dynamic Monitoring for Tennis Injury Prevention and Awareness

Olivia Luke, Dominic Hall, Gabe Dunn, Isabella Hasaj, Adithya Laasko, and Arianna Crossman collaborated to create a device aimed at preventing tennis-related injuries. Their project was guided by Dr. Smitha Rao and supported by Michigan Tech.

Third Place: Team 210 – Vision System for Parts Assembly Process

Ethan Plummer, Madelyn Jackson, MacKenzie Stevens, and Janae Koetje designed and developed a verification system utilizing AI-equipped vision technology. Their innovative system was advised by Dr. Jingfeng Jiang and Dr. Sean Kirkpatrick, with sponsorship from NASA.

Honorable Mentions:

- Team 228 – Simulation-Based Human Body Impedance Modeling for Realistic IEC Defibrillation Safety Standards

Cate Roelant, Emily Dowdy, and Simon Rhode worked to develop a human body impedance simulation model that would enable more accurate and cost-effective testing limits for medical devices. Advised by Orhan Soykan and Jeremy Goldman and sponsored by the U.S. FDA. - Team 216 – LIDAR-based Ice Detection (LID)

Brennan Vrba, Michael Rozzano, Connor Prodin, Austin Champine, Logan Gehring, and Connor Morey worked to develop a system for more accurately detecting ice buildup on aircrafts using LIDAR. Their project was advised by Dr. Tony Pinar, and sponsorship was given by SICK and the ECE departments. - Team 231 – Developing Infrared/Visible Light Therapies for the Bathroom

Hope Gibbons, Miles Cornils, Daniel Bowes, and Ryan Moreau researched the options for a light therapy system that can be effectively used in wet environments. Their team was advised by Sean Kirkpatrick and Chunxiu (Traci) Yu and sponsored by Kohler. - Team 235 – Moonstep: Hypo-Gravity Simulator for Lunar Locomotion Modeling

Parker Courte-Rathwell, Danny Ezzo, and Ingrid Halverson designed a simulator to study movement in lunar gravity conditions. Their innovative project was advised by Dr. Tan Chen and Dr. Steven Elmer, with sponsorship from NASA.

Image Contest Winners

The Design Expo also featured an Image Contest, celebrating the visual storytelling of student projects. Winning images captured the essence of innovation, teamwork, and the vibrant spirit of the expo.

- First Place: TIE – SENSE Enterprise

This stunning overhead image showcases the SENSE Marine Energy Collegiate Competition team on the GLRC waterfront. - First Place: TIE – Formula SAE Enterprise

This captivating image showcases the team at the Toronto shootout. - Second Place: Multiplanetary INnovations Enterprise (MINE)

A dynamic portrayal ATLAS’ first simulated lunar sandbox test with zero-point turn tracks.

The 2025 Design Expo not only celebrated a quarter-century of innovation but also set the stage for future breakthroughs. It’s clear that Michigan Tech’s students continue to push the boundaries of innovation, tackling some of the most pressing challenges facing our world today. The talent, creativity, and dedication showcased at this year’s event are a testament to the exceptional education and hands-on learning that the university fosters.

Congratulations to all participants, advisors, and sponsors who made this event a resounding success! Your hard work and ingenuity have set a new benchmark for future design and engineering projects. As we look to the future, it’s exciting to imagine how these projects will evolve and contribute to a better tomorrow. The success of Design Expo 2025 is just the beginning—Michigan Tech’s commitment to developing the next generation of leaders in technology and innovation is stronger than ever.

We can’t wait to see what the next 25 years will bring.