A diverse, multitalented group of Michigan Tech students and faculty have been awarded fellowships and grants totaling an impressive $71,728 from the Michigan Space Grant Consortium (MSGC) for its 2024-25 cycle.

The MSGC, which consists of 52 consortia, is sponsored by the National Aeronautics and Space Administration (NASA). The MSGC promotes awareness, research and education in “space-related science and technology in Michigan.” To achieve this goal, the organization not only funds fellowships and scholarships for students pursuing STEM careers but also financially supports curriculum enhancement and faculty development.

Michigan Tech Undergraduate Students Who Received $4,000 for Faculty Led Fellowships

- Grace Hoeppner (biomedical engineering): “Effects of Microgravity on Predisposing Factors for Atrial Fibrillation Thrombosis Risk”

- Grace Murray (social sciences): “Cultivating Healthy Communities: A Mixed-Methods Analysis of Female Eponyms in Heirloom Plant Varieties and their Impacts in Community Food Networks”

Michigan Tech Graduate Students Who Received $5,000 Graduate Fellowships

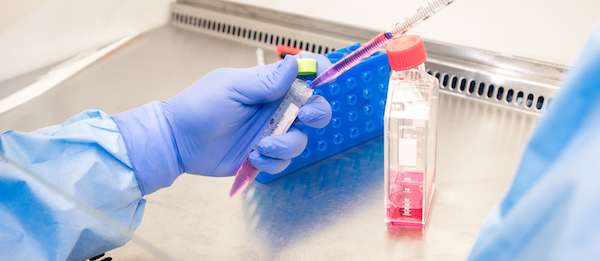

- Alexander Apostle (Chem): “Improved Synthesis and Application of Human Telomeres”

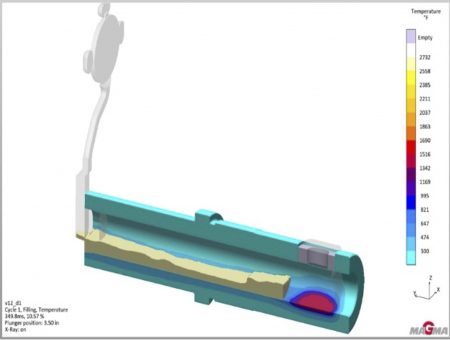

- Matthew Beals (ME-EM): “Advancing Adaptive Aerostructures: Utilizing Steady-State Traveling Waves for Drag Reduction and Sustainable Aviation”

- Grady Boyle (CFRES): “Using High Resolution Multitemporal Imagery for Ash Inventory and EAB Invasion Mapping in the Upper Great Lakes Region”

- Jacob Jackson (BioMed): “Cell-Specific Adaptive Deep Brain Stimulation in the Subthalamic Nucleus of a Parkinson’s Rat Model”

- Benjamin Mohrhardt (ECE): “Investigating and Predicting the Formation of Toxic Nitrogenous Byproducts from Phenolic Compounds in the Presence of Nitrate under Far-UVC Irradiation from KrCl* Excilamps”

- Ian Norwood (Physics): ”Constraining Frictional Charging on Coarse-Mode Atmospheric Dust Particles”

- Eleanor Serocki (CFRES): ”Estimating Trace Gas Flux Dynamics in Boreal Wetlands”

- Tanner Sether (Physics): ”Toward a Deep Learning Approach for Fast Galaxy Catalog Generation”

- Matthew Sisson (MSE): ”Micromagnetism of Self-Assembled FeSi2 Nanoislands”

- Caitlyn Sutherlin (SS): ”Community- and Nature-Led Adaptation in El Salvador”

- Kyle Wehmanen (KIP): ”Human Powered Locomotion on Variable Terrain: a Continuing Investigation for how to Move on Mars”

Michigan Tech Faculty and Staff Members Who Received $5,000 or More for Hands-On NASA-Oriented Experiences for Student Groups (HONES) or Research Seed Grants

- Paul van Susante (ME-EM): HONES — “NASA Lunabotics Competition”

The Graduate School is proud of these students for their outstanding scholarship. These awards highlight the quality of students at Michigan Tech, their innovative work, their leadership potential and the incredible role played by faculty in students’ academic success.